1. ņä£ ļĪĀ

ņ░©ļ¤ēņÜ® ņ£Āņ▓┤Ēü┤ļ¤¼ņ╣ś ļ░Å ņ£Āņ▓┤ĒÄīĒöäņŚÉņä£ ņ£Āņ▓┤ņØś ņĢĢļĀźņ£╝ļĪ£ ņØĖĒĢ┤ņä£ ĒÜīņĀäĒĢśļŖö ļČĆĒÆłņ£╝ļĪ£ ņ×äĒÄĀļ¤¼ ļĖöļĀłņØ┤ļō£Ļ░Ć ņ׳ļŗż. ĒåĄņāüņĀüņ£╝ļĪ£ ļåÆņØĆ ņĢĢļĀźņØä ļ░øņØīņ£╝ļĪ£ ņØĖĒĢśņŚ¼ ļåÆņØĆ ņØæļĀźĻ│╝ ļ│ĆĒśĢņØ┤ ļ░£ņāØĒĢśĻ▓ī ļÉśļŖöļŹ░, ņØ┤ļ¤¼ĒĢ£ ļĖöļĀłņØ┤ļō£ļź╝ ņÜ®ņĀæĒĢĀ ņŗ£ņŚÉļŖö ņĢĢļĀźņ£╝ļĪ£ ņØĖĒĢ£ ĒŚłņÜ®ņØæļĀźņØä Ļ│äņé░ĒĢśĻ│Ā, ņØ┤ļź╝ ĒåĄĒĢ┤ņä£ ņÜ®ņĀæĻĄ¼Ļ░ä(ĻĖĖņØ┤ ļśÉļŖö ĒÅŁ) ņäżĻ│äĻ░Ć ņØ┤ļŻ©ņ¢┤ņĀĖņĢ╝ ĒĢ£ļŗż.

ļĖöļĀłņØ┤ļō£ņŚÉ Ļ░ĆĒĢ┤ņ¦ĆļŖö ņÖĖļČĆ ĒלņØĆ ļŗ©ņł£ ņĢĢļĀźļ┐Éļ¦ī ņĢäļŗłļØ╝ ņøÉņŗ¼ļĀźņŚÉ ņØśĒĢ£ ņØæļĀź ļō▒ ļ│Ąņ×ĪĒĢ£ ĒśĢĒā£ņØś ļ│ĄĒĢ®ņØæļĀźņØ┤ ļ░£ņāØĒĢśļŖöļŹ░, ļŗ©ņł£ĒĢ£ ņØ┤ļĪĀņĀü ĒĢ┤ņäØļ░®ļ▓Ģņ£╝ļĪ£ļŖö ņśłņĖĪņØ┤ ņ¢┤ļĀżņøīņä£ ņ╗┤Ēō©Ēä░ļź╝ ņØ┤ņÜ®ĒĢ£ ņĀäņé░ĒĢ┤ņäØņØ┤ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ļŗż

1,2).

ņØ┤ļ¤¼ĒĢ£ ņĀäņé░ĒĢ┤ņäØņĀüņØĖ ĻĄ¼ņĪ░ņŗ£ĒŚśĻ│╝ ņ£ĀĒĢ£ņÜöņåīĒĢ┤ņäØņØä ĒåĄĒĢśņŚ¼, ņ£Āņ▓┤ĻĖ░Ļ│äņÜ® ļĖöļĀłņØ┤ļō£ ļ┐Éļ¦ī ņĢäļŗłļØ╝ ļŗżņ¢æĒĢ£ ĒśĢĒā£ņØś ņåīĒśĢ ĒÆŹļĀźļ░£ņĀäņÜ® ļ│ĄĒĢ®ņ×¼ ļĖöļĀłņØ┤ļō£ņØś ņĢłņĀäņä▒ņØ┤ļéś, ņĀĢĻ▓® ļ░Å ĻĘ╣ĒĢ£ ĒÆŹņåŹņØ╝ ļĢīņØś ļĖöļĀłņØ┤ļō£ņØś ĒĢ┤ņäØļÅä Ļ░ĆļŖźĒĢśļŗż

2,3).

ļĀłņØ┤ņĀĆ ņÜ®ņĀæņØĆ ļåÆņØĆ ņĀĢņĀÉņČ£ļĀźņØä Ļ░Ćņ¦ĆļŖö ņŚÉļäłņ¦Ćļź╝ ĻĄŁņåī ļČĆļČäņŚÉ ņ¦¦ņØĆ ņŗ£Ļ░äļÅÖņĢł ņåīņ×ģ ĒĢ©ņ£╝ļĪ£ņä£ ņŚ┤ņśüĒ¢źļČĆļź╝ ņĄ£ņåīĒÖö ĒĢĀ ņłś ņ׳Ļ│Ā, ļ╣ĀļźĖ ļāēĻ░üņåŹļÅäļĪ£ ņØĖĒĢ┤ņä£ ņÜ®ņĀæ Ēøä ļ│ĆĒśĢļÅä ĒāĆ ņÜ®ņĀæļ▓ĢņŚÉ ļ╣äĒĢ┤ņä£ ņĄ£ņåīĒÖö ĒĢĀ ņłś ņ׳ļŖö ņןņĀÉņØ┤ ņ׳ļŗż

4). ĒĢśņ¦Ćļ¦ī, Ļ│Āļ░ĆļÅä ņŚÉļäłņ¦Ć ņÜ®ņĀæņØĆ ņÜ®ņĀæļČĆņØś ļāēĻ░üņåŹļÅäņÖĆ ņś©ļÅäĻĄ¼ļ░░Ļ░Ć ļ¦żņÜ░ ņ╗żņä£ ņĘ©ņä▒ņĪ░ņ¦üĻ│╝ Ēü░ ņ×öļźśņØæļĀźņØä ĒśĢņä▒ĒĢĀ ņłśļÅä ņ׳ņ¢┤ņä£ ņÜ®ņĀæņäżĻ│ä ņĀäņŚÉ ņÜ®ņĀæļČĆ ļ░Å ļ¬©ņ×¼ņŚÉ ņ×æņÜ®ĒĢśļŖö ņØæļĀź ļ░Å ļ│ĆĒśĢļ¤ēņŚÉ ļīĆĒĢ£ ņé¼ņĀäĻ▓ĆĒåĀĻ░Ć ļ░śļō£ņŗ£ ĒĢäņÜöĒĢśļ®░, ņ£ĀĒĢ£ ņÜöņåīļ▓ĢņØ┤ ĒÜ©Ļ│╝ņĀüņ£╝ļĪ£ ņé¼ņÜ®ļÉĀ ņłś ņ׳ļŗż. ņÜ®ņĀæļČĆĻ░Ć ĻĖĖĻ│Ā ļäōņ¢┤ņ¦łņłśļĪØ, ņÜ®ņĀæļČĆņ£äņŚÉ ņ×æņÜ®ĒĢśļŖö ņØæļĀźņØä ņāüļīĆņĀüņ£╝ļĪ£ ņżäņØ╝ ņłś ņ׳ņ¢┤ņä£ ņÜ®ņĀæņŗĀļó░ļÅäļŖö Ē¢źņāüļÉśļéś, ņÜ®ņĀæļČĆņŚÉ Ļ░ĆĒĢ┤ņ¦ĆļŖö ņŚ┤ļĪ£ ņØĖĒĢ┤ ļ│ĆĒśĢņØ┤ ņ╗żņ¦ĆļŖö ļŗ©ņĀÉļÅä ņ׳ļŗż.

ļ│Ė ļģ╝ļ¼ĖņŚÉņä£ļŖö

Fig. 1ņŚÉņä£ ņśłņŗ£ļÉ£ ļ░öņÖĆ Ļ░ÖņØ┤ Ļ│ĀņĢĢņØ┤ ņĀüņÜ®ļÉśļŖö ļĖöļĀłņØ┤ļō£ļź╝ ļĀłņØ┤ņĀĆ ņÜ®ņĀæņŗ£, ļĀłņØ┤ņĀĆ ņÜ®ņĀæļČĆņ£ä ņĄ£ņĀüņäżĻ│ä(ļČĆļČä ņÜ®ņĀæ vs. ņĀäņ▓┤ ņÜ®ņĀæ)ļź╝ ĒåĄĒĢ┤ņä£ Ļ░ü ņĪ░Ļ▒┤ ļ│ä ļĖöļĀłņØ┤ļō£Ļ░Ć ļ░øļŖö ņØæļĀźĻ│╝ ļ│ĆĒśĢļ¤ēņØä ĒĢ┤ņäØĒĢśļŖö ļ░®ļ▓Ģ ļ░Å Ļ▓░Ļ│╝ņŚÉ ļīĆĒĢ£ ļé┤ņÜ®ņØä ļ│┤Ļ│ĀĒĢśĻ│Āņ×É ĒĢ£ļŗż.

Fig.┬Ā1

3D modeling of impeller blade

2. ļ│Ė ļĪĀ

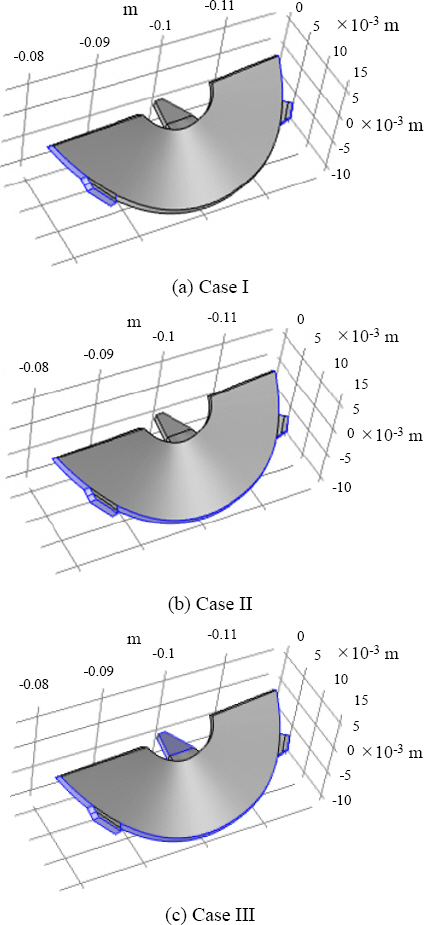

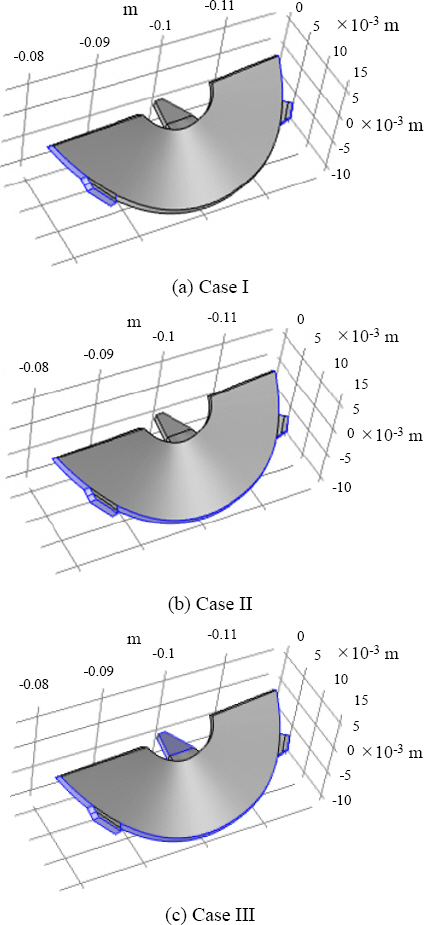

ļ│Ė ņŚ░ĻĄ¼ņŚÉņä£ļŖö ļĀłņØ┤ņĀĆ ņÜ®ņĀæņŗ£, ļĖöļĀłņØ┤ļō£ Ļ│ĀņĀĢņØä ņ£äĒĢ┤ņä£ ĒĢśļČĆ ĒāŁ Ļ│ĀņĀĢ (

Fig. 2a), ĒĢśļČĆ ņĀä ņśüņŚŁ Ļ│ĀņĀĢ (

Fig. 2b), ĻĘĖļ”¼Ļ│Ā ĒĢśļČĆ ņĀä ņśüņŚŁĻ│╝ ņāüļČĆ ĒāŁ Ļ│ĀņĀĢ (

Fig. 2c)ņØś ņäĖ Ļ░Ćņ¦Ć Ļ▓ĮņÜ░ļź╝ Ļ░ĆņĀĢĒĢśĻ│Ā, Ļ░üĻ░üņØś Ļ▓ĮņÜ░ņŚÉ ļīĆĒĢ£ ņŗ£ļ«¼ļĀłņØ┤ņģś Ļ▓░Ļ│╝ļź╝ ņä£ļĪ£ ļ╣äĻĄÉ Ļ▓Ćņ”Ø ĒĢśņśĆļŗż. ņŗ£ļ«¼ļĀłņØ┤ņģśņŚÉ ņé¼ņÜ®ļÉ£ ņåīņ×¼ļŖö AISI 4340ņØ┤ļ®░ ņāüņäĖ ļ¼╝ņä▒ņ╣śļŖö

Table 1ņŚÉ ĻĖ░ņłĀ ĒĢśņśĆļŗż

5).

Fig.┬Ā2

Case study of laser welding simulation

Table┬Ā1

Mechanical properties of AISI 4340

5)

|

Yield strength, MPa |

Tensile strength, MPa |

Elastic modules, GPa |

Hardness, HV |

|

470 |

745 |

190-210 |

43 |

ņŗ£ļ«¼ļĀłņØ┤ņģś ņĪ░Ļ▒┤ņ£╝ļĪ£ ļĖöļĀłņØ┤ļō£Ļ░Ć ļ░øļŖö ņĢĢļĀźņØä 1MPaņŚÉņä£ 5MPa ļ▓öņ£äļĪ£ ņäżņĀĢĒĢśĻ│Ā, Ēæ£ļ®┤ņŚÉ Normal ĒĢ£ ļ░®Ē¢źņ£╝ļĪ£ Ļ░ĆņĢĢļ░®Ē¢źņØä ņäżņĀĢĒĢśņśĆĻ│Ā, ņ×Éņ£ĀļÅä ĻĄ¼ņåŹ(constraints)ņØĆ x,y,z ļ░®Ē¢źņ£╝ļĪ£ ņäżņĀĢ ĒĢśņśĆļŗż. ļĖöļĀłņØ┤ļō£Ļ░Ć Ļ│ĀņåŹņ£╝ļĪ£ ĒÜīņĀäņŗ£ ņøÉņŗ¼ļĀźņŚÉ ņØśĒĢ£ ņØæļĀźļÅä ļ░£ņāØļÉśņ¦Ćļ¦ī, ļ│Ė ņŚ░ĻĄ¼ņŚÉņä£ļŖö ņĢĢļĀź ņĪ░Ļ▒┤ņØś ņśüĒ¢źļ¦ī Ļ│Āņ░░ĒĢśĻĖ░ ņ£äĒĢ┤ ņøÉņŗ¼ļĀźņŚÉ ņØśĒĢ£ ņØæļĀźļ░£ņāØņØĆ ņĀ£ņÖĖ ĒĢśņśĆļŗż.

Fig. 2ņŚÉņä£ļŖö ņÜ®ņĀæ ļČĆļź╝ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁ Ļ│ĀņĀĢ(Case I), ĒĢśļČĆ ņĀä ņśüņŚŁ Ļ│ĀņĀĢ(Case II), ĻĘĖļ”¼Ļ│Ā ĒĢśļČĆ ņĀä ņśüņŚŁĻ│╝ ņāüļČĆ ĒāŁ Ļ│ĀņĀĢ(Case III)ņ£╝ļĪ£ ĻĄ¼ļČä ĒĢśņśĆļŗż.

ļśÉĒĢ£, ņåīņ×¼ ĒīīņåÉņŚÉ ļīĆĒĢ£ ĒīÉļ│äņĪ░Ļ▒┤ņ£╝ļĪ£ ņåīņ×¼ņŚÉ Ļ░ĆĒĢ┤ņ¦ĆļŖö ĒĢŁļ│ĄņØæļĀźĻ│╝ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØä Ļ│äņé░ĒĢśņśĆņ£╝ļ®░, ņØ┤ļź╝ ņ£äĒĢ┤ņä£ COMSOL Multiphysics Ver. 5.3ņØä ņé¼ņÜ®ĒĢśņśĆĻ│Ā, Ļ▓Ćņ”Ø ļÉ£ Solid Mechanics ļ¬©ļōłņØä ņĀüņÜ®ĒĢśņśĆļŗż.

3. Ļ▓░ Ļ│╝

3.1 ņØæļĀź ļČäĒż (Stress distribution analysis)

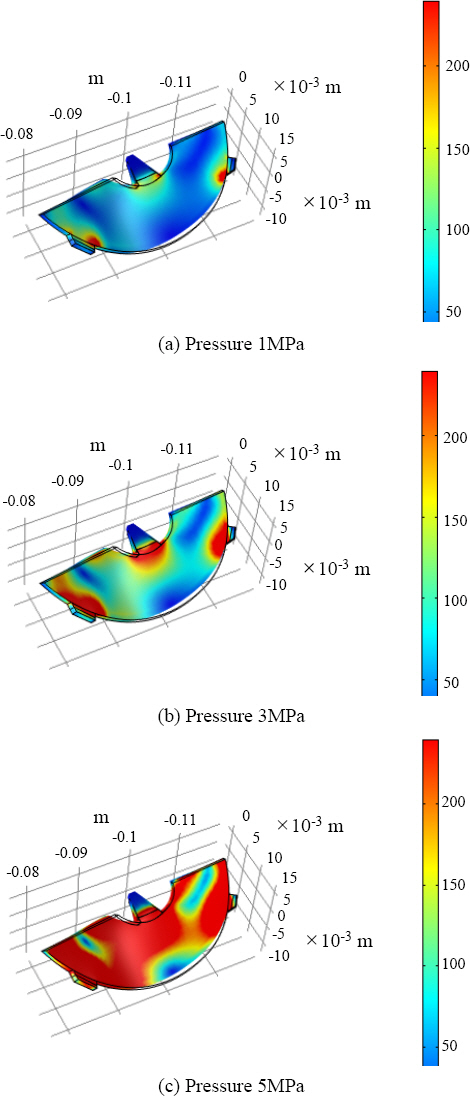

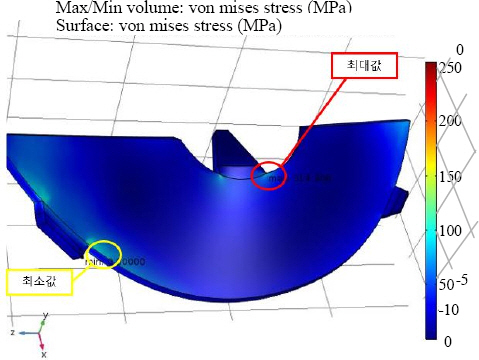

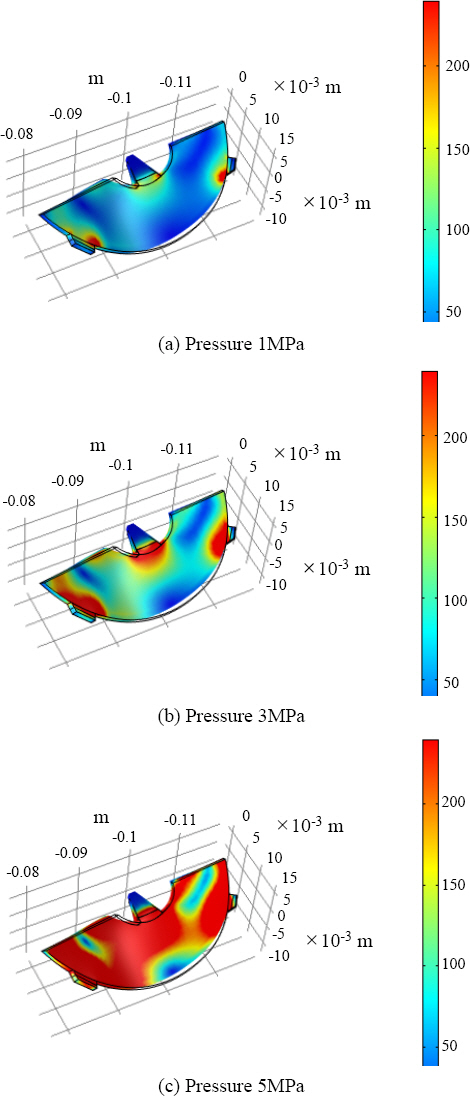

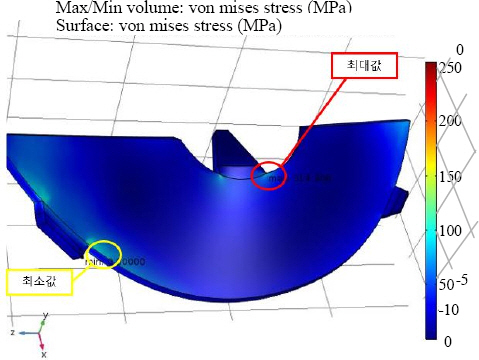

ņåīņ×¼ņŚÉ Ļ░ĆĒĢ┤ņ¦ĆļŖö ņĢĢļĀźņŚÉ ļö░ļźĖ ņØæļĀźļČäĒżļź╝ ņĢīņĢä ļ│┤ĻĖ░ ņ£äĒĢ┤ņä£ 1MPaņŚÉņä£ 5MPa ļ▓öņ£äņØś ņ£Āņ▓┤ņĢĢļĀźņØä ļĖöļĀłņØ┤ļō£ Ēæ£ļ®┤ņŚÉ Ļ░ĆĒĢśļ®┤ņä£, Von Mises ņØæļĀźņØä Ļ│äņé░ ĒĢśņśĆļŗż. ļŗżņ¢æĒĢ£ ņĢĢļĀź ĒĢśņŚÉņä£ņØś Von Mises ņØæļĀźļČäĒż Ļ│äņé░ĒĢśĻ│Ā, ņØ┤Ēøä Von Mises ņØæļĀźņØ┤ ņåīņ×¼ņØś ĒŚłņÜ® ĒĢŁļ│ĄĻ░ĢļÅäņØś ņ┤łĻ│╝ņŚ¼ļČĆļź╝ Ļ┤Ćņ░░ĒĢśņśĆĻ│Ā, Ļ▓░Ļ│╝ļź╝

Fig. 3ņŚÉ ņĀĢļ”¼ ĒĢśņśĆļŗż.

Fig.┬Ā3

Stress distribution on the blade (Case I, unit MPa)

Fig. 3ņŚÉ ļéśĒāĆļé┤ ļ░öņÖĆ Ļ░ÖņØ┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆņØæļĀźņØ┤ 250MPa ļé┤ņÖĖļĪ£ ņŻ╝ļĪ£ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁ ņŻ╝ņ£äņŚÉ ņØæļĀźņØ┤ ņ¦æņżæņØ┤ ļÉśņŚłļŗż. ņØ┤ļŖö ņĢĢļĀźņØ┤ Ļ░ĆĒĢ┤ņ¦ł ņŗ£ņŚÉ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁņØś ĻĄ┤Ļ│ĪļČĆņŚÉ ņØæļĀźņØ┤ ņ¦æņżæņØ┤ ļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż. ĒĢśņ¦Ćļ¦ī, ļĖöļĀłņØ┤ļō£ Ēæ£ļ®┤ņŚÉļŖö ļīĆļČĆļČä 100MPa ņØ┤ĒĢśņØś ņāüļīĆņĀüņ£╝ļĪ£ ņ×æņØĆ ņØæļĀźļČäĒżĻ░Ć ļ░£ņāØ ļÉśņŚłļŗż.

ņĢĢļĀźņØ┤ 3MPaļĪ£ ņāüņŖ╣ņŗ£ņŚÉļŖö ļĖöļĀłņØ┤ļō£ ņāüĒĢś ĒāŁ ļČĆļČä ņŻ╝ņ£äļĪ£ ņĀÉņ░©ņĀüņ£╝ļĪ£ ņØæļĀźņØ┤ ņāüņŖ╣ĒĢśļŖö Ļ▓āņØä ļ│╝ ņłśĻ░Ć ņ׳ņŚłņ£╝ļ®░, ņĄ£Ļ│Ā ņĢĢļĀźņØĖ 5MPaņØś Ļ▓ĮņÜ░ņŚÉņä£ļŖö ņĀä ņśüņŚŁņŚÉņä£ ĒĢŁļ│ĄĻ░ĢļÅäļź╝ ņ┤łĻ│╝ĒĢśļŖö ņØæļĀźņØ┤ ĒśĢņä▒ļÉ©ņØä ņĢī ņłś ņ׳ņŚłļŗż.

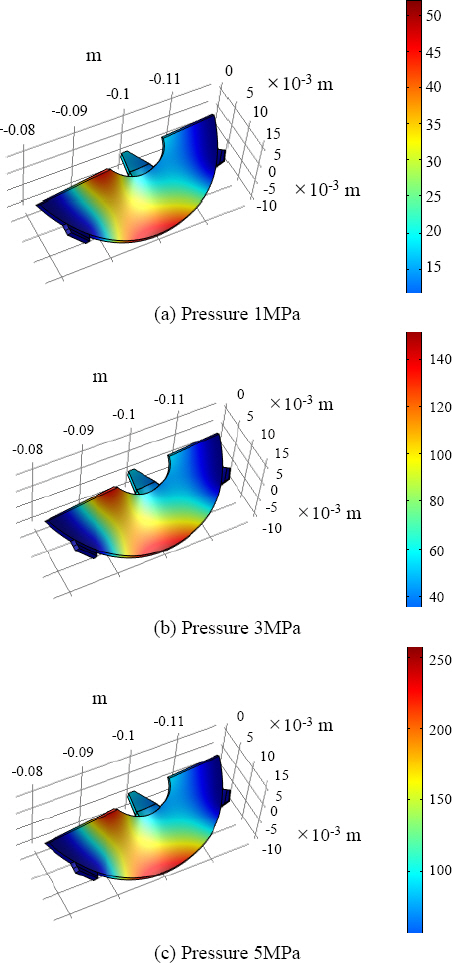

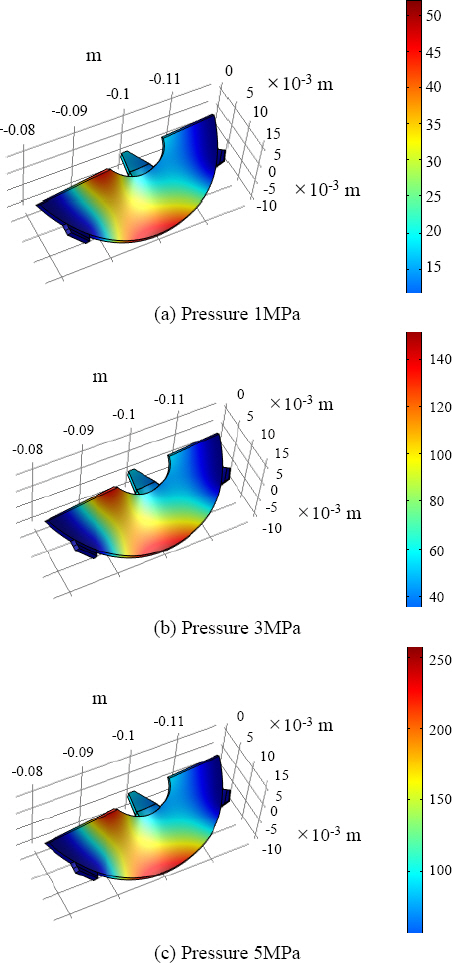

Fig. 4ņØś Ļ▓ĮņÜ░ļŖö ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ņśüņŚŁņØä ņĀäņ▓┤ņĀüņ£╝ļĪ£ ĻĄ¼ņåŹĒĢ£ Ļ▓ĮņÜ░ņØ┤ļ®░, ņØ┤ļŖö ļĀłņØ┤ņĀĆ ņÜ®ņĀæņŗ£ ĒĢśļČĆņśüņŚŁņØä ņĀäņ▓┤ņĀüņ£╝ļĪ£ ņĀæĒĢ®ĒĢ£ Ļ▓ĮņÜ░ļź╝ Ļ░ĆņĀĢĒĢśņŚ¼ ņŗ£ļ«¼ļĀłņØ┤ņģś ĒĢ£ Ļ▓āņØ┤ļŗż.

Fig.┬Ā4

Stress distribution on the blade (Case II, unit MPa)

Ļ▓░Ļ│╝ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆņØæļĀźņØ┤ 250MPa ņØ┤ņāüņ£╝ļĪ£ ļ░£ņāØ ļÉśņŚłļŖöļŹ░, ņØ┤ļŖö ņĢ×ņäĀ Case IņØś Ļ▓ĮņÜ░ņÖĆ ļ¦łņ░¼Ļ░Ćņ¦ĆļĪ£ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁ ņŻ╝ņ£äņŚÉ ņØæļĀźņ¦æņżæņØ┤ ļ░£ņāØ ļÉśņŚłļŗż.

ņĢĢļĀźņØä 3MPaĻ│╝ 5MPaļĪ£ ļŹö Ļ░ĆĒĢśņśĆņØä ļĢīņŚÉļÅä ņØ┤ļ¤¼ĒĢ£ ņØæļĀźļČäĒż ĒśäņāüņØĆ ļ╣äņŖĘĒĢ£ Ļ▓ĮĒ¢źņØä ļ│┤ņśĆņ£╝ļ®░, ņĀäņ▓┤ņĀüņ£╝ļĪ£ ņØæļĀźņØś Ēü¼ĻĖ░ļ¦ī ņ”ØĻ░ĆĒĢśļŖö Ļ▓āņØä ņĢī ņłśĻ░Ć ņ׳ņŚłļŗż.

Fig. 5ņØś Ļ▓ĮņÜ░, ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ņśüņŚŁļ┐Éļ¦ī ņĢäļŗłļØ╝ ņāüļČĆ ņśüņŚŁņØś ĒāŁ ļČĆļČäĻ╣īņ¦Ć ĻĄ¼ņåŹĒĢ£ Ļ▓ĮņÜ░ņØ┤ļ®░, ņØ┤ļŖö ļĀłņØ┤ņĀĆ ņÜ®ņĀæņŗ£ ĒĢśļČĆņśüņŚŁņØä ņĀäņ▓┤ņĀüņ£╝ļĪ£ ņĀæĒĢ®ĒĢ£ Ļ▓ĮņÜ░ņÖĆ ļŹöļČłņ¢┤ ņāüļČĆ ĒāŁ ļČĆļČäņØä ņÜ®ņĀæĒĢ£ ņé¼ļĪĆļź╝ ņŗ£ļ«¼ļĀłņØ┤ņģś ĒĢ£ Ļ▓āņØ┤ļŗż.

Fig.┬Ā5

Stress distribution on the blade (Case III unit MPa)

Ļ▓░Ļ│╝ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤, 1MPaņŚÉņä£ļÅä ņĄ£ļīĆņØæļĀźņØ┤ ņåīņ×¼ņØś Ēīīļŗ©Ļ░ĢļÅä ņØ┤ņāüņ£╝ļĪ£ ļ░£ņāØĒĢ©ņØä ņĢī ņłśĻ░Ć ņ׳ņŚłļŗż. ļŗżļ¦ī, ņØ┤ļ¤¼ĒĢ£ ņ╣śļ¬ģņĀü ņØæļĀźņ¦æņżæņØĆ ļĖöļĀłņØ┤ļō£ ņĀä ņśüņŚŁ ņżæņŚÉņä£ ņĢäņŻ╝ ļ»ĖņåīņśüņŚŁņŚÉņä£ ļ░£ņāØĒĢśņśĆņ£╝ļ®░, ļīĆļČĆļČäņØś ņśüņŚŁņŚÉņä£ļŖö ĒĢŁļ│ĄĻ░ĢļÅä ņØ┤ĒĢśņØś ņØæļĀźņØ┤ ļ░£ņāØĒĢ©ņØä ņĢī ņłś ņ׳ņŚłļŗż. ņØ┤ļ¤¼ĒĢ£ Ļ▓░Ļ│╝ļź╝ ņóĆ ļŹö ņäĖļČäĒÖöĒĢśņŚ¼ ņé┤ĒÄ┤ ļ│┤ĻĖ░ ņ£äĒĢ┤ņä£ ņØæļĀź ņĄ£ļīĆņĀÉĻ│╝ ņĄ£ņåī Ļ░ÆņØä ņČöņĀüĒĢśņśĆļŗż.

Ļ▓░Ļ│╝ņĀüņ£╝ļĪ£

Fig. 6ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤, ņØæļĀź ņĄ£ņåīņśüņŚŁņØĆ ļĖöļĀłņØ┤ļō£ ņāüļČĆ ĒāŁņØś ņ×Éņ£ĀņśüņŚŁņØ┤ļ®░, ņĄ£ļīĆņśüņŚŁņØĆ ļĖöļĀłņØ┤ļō£ ņāüļČĆ ĒāŁņØś ņĮöļäłļČĆ ņśĆļŗż. ļö░ļØ╝ņä£, ņäżĻ│äņŗ£ ļĖöļĀłņØ┤ļō£ ņāüļČĆ ĒāŁņØś ņĮöļäł ļČĆņ£äņŚÉ ņØæļĀźņØ┤ ņ¦æņżæ ļÉśņ¦Ć ņĢŖļÅäļĪØ fillet ļō▒ņØś ņ▓£ņØ┤ņśüņŚŁņØä ļæÉĻ▓ī ļÉśļ®┤, ņØ┤ļ¤¼ĒĢ£ ņØæļĀźņ¦æņżæņŚÉ ņØśĒĢ£ ņåīņ×¼Ēīīļŗ©ņØä ņĄ£ņåīĒÖö ĒĢĀ ņłś ņ׳ņØä Ļ▓āņ£╝ļĪ£ ĻĖ░ļīĆ ļÉ£ļŗż.

Fig.┬Ā6

Max. and min. stress locations

3.2 ļ│ĆĒśĢļ¤ē ļČäĒż (displacement distribution analysis)

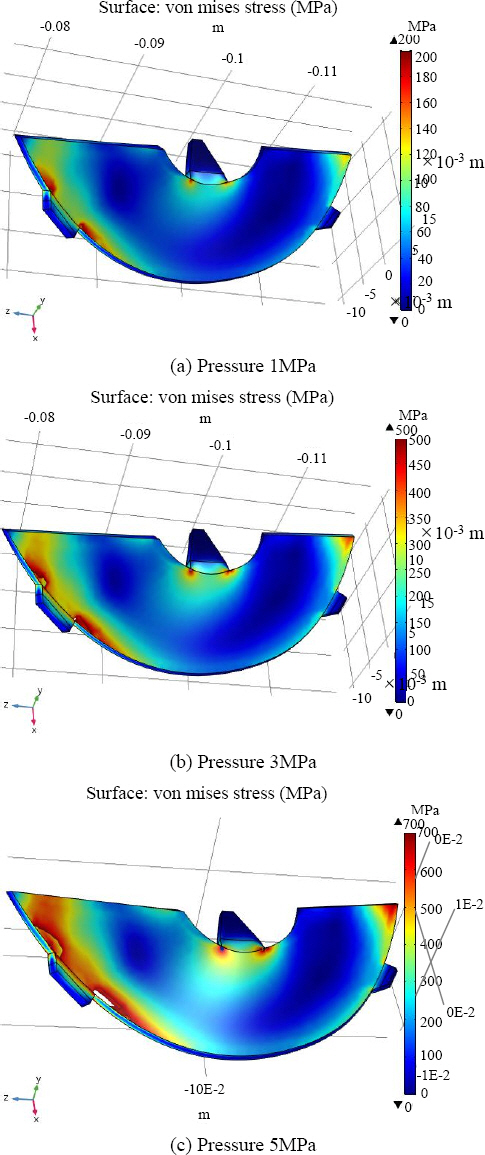

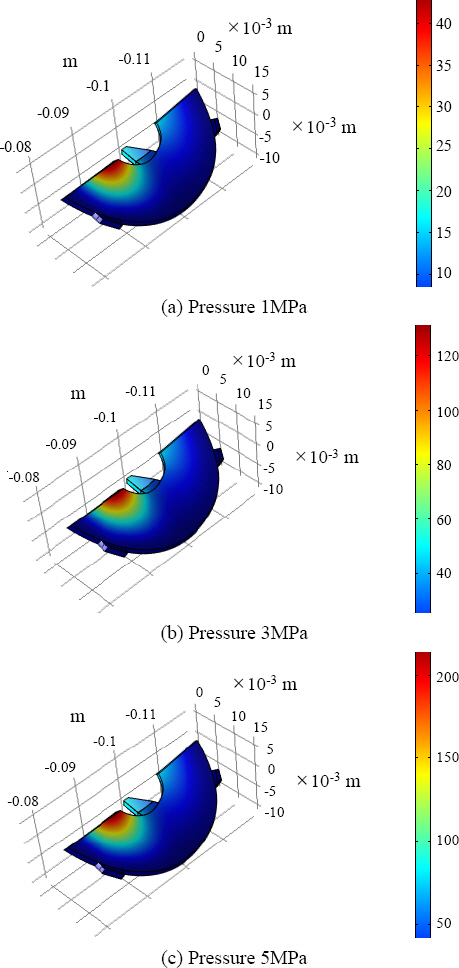

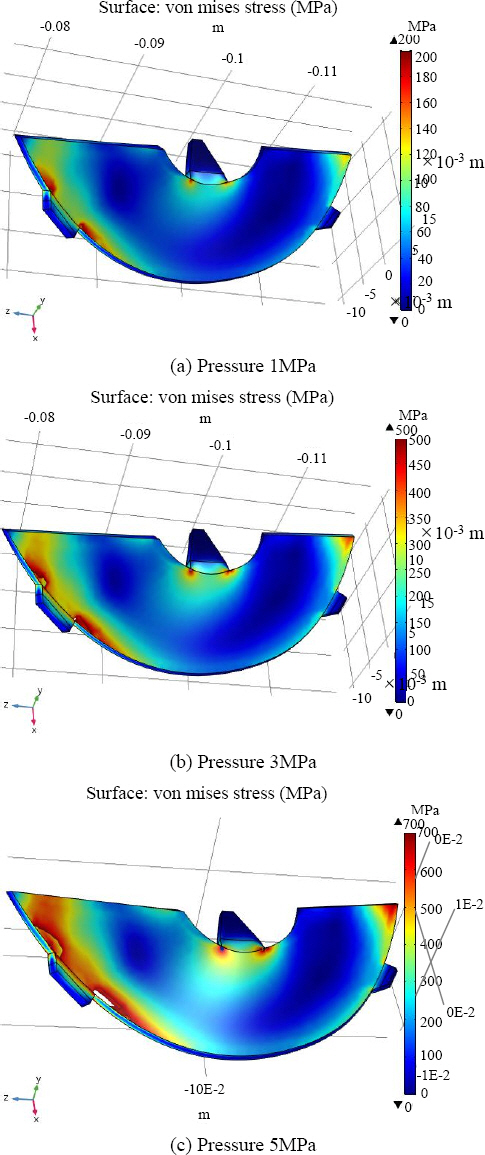

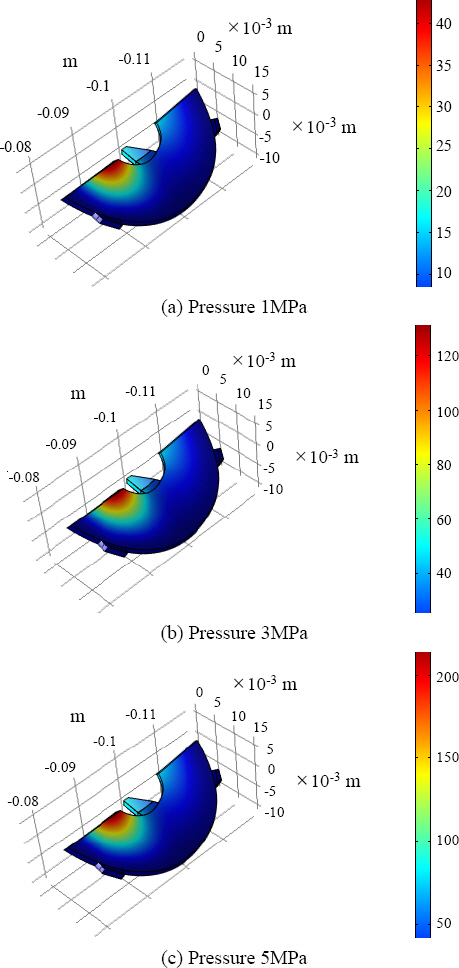

3.1ņĀłĻ│╝ ļÅÖņØ╝ĒĢ£ Ļ░ĆņĀĢņŚÉņä£ ļ│ĆĒśĢļ¤ēņØä ņČöņĀüĒĢśņśĆļŗż. ņåīņ×¼ņØś ļ│ĆĒśĢļ¤ēņØä ņĢīņĢäļ│┤ĻĖ░ ņ£äĒĢ┤ņä£ 1MPaņŚÉņä£ 5MPa ļ▓öņ£äņØś ņ£Āņ▓┤ņĢĢļĀźņØä ļĖöļĀłņØ┤ļō£ Ēæ£ļ®┤ņŚÉ Ļ░ĆĒĢśļ®┤ņä£, total displacement fieldļź╝ ņČöņĀü Ļ│äņé░ ĒĢśņśĆļŗż. ļŗżņ¢æĒĢ£ ņĢĢļĀźĒĢśņŚÉņä£ņØś ļ│ĆĒśĢļ¤ē Ļ│äņé░ Ļ▓░Ļ│╝ļź╝

Fig. 7ņŚÉ ņĀĢļ”¼ ĒĢśņśĆļŗż.

Fig.┬Ā7

Displacement distribution on the blade (Case I, unit ╬╝m)

Fig. 7 (Case I)Ļ│╝ Ļ░ÖņØ┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ 50╬╝m ļé┤ņÖĖļĪ£ ņŻ╝ļĪ£ ļĖöļĀłņØ┤ļō£ ņāüĒĢśļČĆ ĒāŁ(ĻĄ¼ņåŹņ£äņ╣ś)ņŚÉņä£ ņāüļīĆņĀüņ£╝ļĪ£ ļ©╝ ņżæņĢÖļČĆņ£äņØĖ Ļ▓āņ£╝ļĪ£ ĒÖĢņØĖ ĒĢśņśĆļŗż. ņØ┤ļŖö ņĢĢļĀźņØ┤ Ļ░ĆĒĢ┤ņ¦ł ņŗ£ņŚÉ ĻĄ¼ņåŹļÉ£ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁņŚÉņä£ ļ│ĆĒśĢļ¤ēņØ┤ ļłäņĀüļÉśņ¢┤ ĻĄ¼ņåŹņ£äņ╣śņŚÉņä£ Ļ░Ćņן ļ©╝ Ļ││ņŚÉ ņĄ£ļīĆ ļ│ĆĒśĢņØ┤ ļ░£ņāØ ļÉ£ Ļ▓āņØ┤ļŗż. ņĢĢļĀźņØ┤ 3MPaņÖĆ 5MPaļĪ£ ņāüņŖ╣ņŗ£ņŚÉ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ 140╬╝m Ļ│╝ 250╬╝m ļé┤ņÖĖņśĆņ£╝ļéś, ņĄ£ļīĆ ļ│ĆĒśĢņ£äņ╣śļŖö 1MPaĻ│╝ ļÅÖņØ╝ ĒĢśņśĆļŗż.

ļÅÖņØ╝ĒĢ£ ņĢĢļĀźņĪ░Ļ▒┤ņØä Case II (ĒĢśļČĆ ņĀäņśüņŚŁņØä ĻĄ¼ņåŹ)ņŚÉ ņĀüņÜ®ĒĢ£ Ļ▓░Ļ│╝ļź╝

Fig. 8ņŚÉ ļÅäņŗ£ ĒĢśņśĆļŗż. Ļ▓░Ļ│╝ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØ┤ 40╬╝m ļé┤ņÖĖ, 3MPaņŚÉņä£ļŖö 120╬╝m ļé┤ņÖĖ, ĻĘĖļ”¼Ļ│Ā 5MPaņŚÉņä£ļŖö 200╬╝m ļé┤ņÖĖļĪ£ Ļ│äņé░ļÉśņŚłļŗż. ņØ┤ļŖö Case I(ĒĢśļČĆ ĒāŁ ņØ╝ļČĆ ĻĄ¼ņåŹ)ņØś Ļ▓ĮņÜ░ļ│┤ļŗż ņāüļīĆņĀüņ£╝ļĪ£ ļ│ĆĒśĢļ¤ēņØ┤ ņĀüĻ▓ī ļ░£ņāØļÉ£ Ļ▓░Ļ│╝ļź╝ ļ│┤ņŚ¼ ņŻ╝Ļ│Ā ņ׳ļŗż. ņØ┤ļŖö ĒĢśļČĆņØś ĻĄ¼ņåŹņśüņŚŁņØ┤ Ēü╝ņŚÉ ļö░ļØ╝ ļ│ĆĒśĢļ¤ēņØ┤ ņāüļīĆņĀüņ£╝ļĪ£ ņĀüĻ▓ī ļ░£ņāØļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

Fig.┬Ā8

Displacement distribution on the blade (Case II, unit ╬╝m)

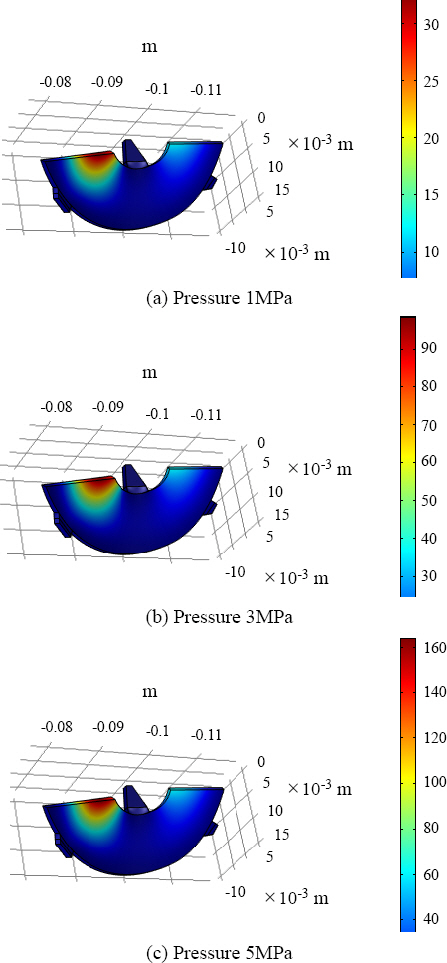

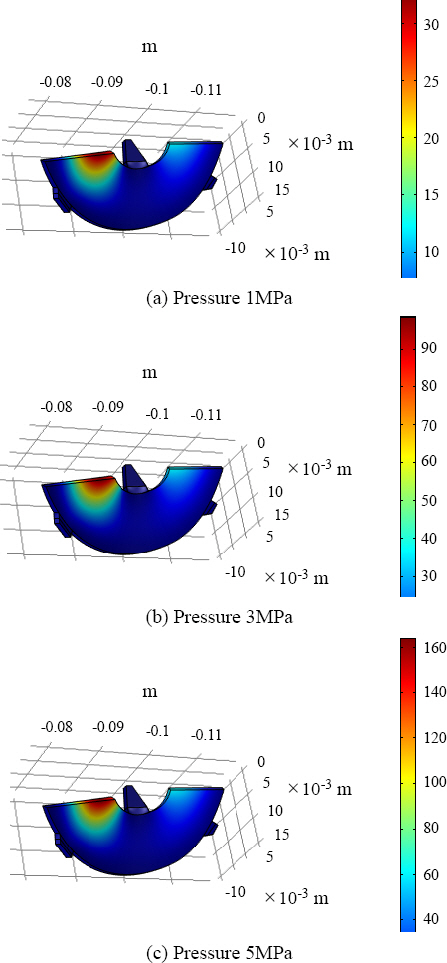

ļÅÖņØ╝ĒĢ£ ņĢĢļĀźņĪ░Ļ▒┤ņØä Case III (ņāüļČĆ ĒāŁ ļ░Å ĒĢśļČĆ ņĀäņśüņŚŁņØä ĻĄ¼ņåŹ)ņŚÉ ņĀüņÜ®ĒĢ£ Ļ▓░Ļ│╝ļź╝

Fig. 9ņŚÉ ļÅäņŗ£ ĒĢśņśĆļŗż. Ļ▓░Ļ│╝ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ 30╬╝m ļé┤ņÖĖ, 3MPaņŚÉņä£ļŖö 90╬╝m ļé┤ņÖĖ, ĻĘĖļ”¼Ļ│Ā 5MPaņŚÉņä£ļŖö 160╬╝m ļé┤ņÖĖļĪ£ Case IĻ│╝ Case IIņŚÉ ļ╣äĒĢ┤ņä£ ĒśäņĀĆĒ׳ ļ│ĆĒśĢļ¤ēņØ┤ ņĀüņŚłļŗż. ņØ┤ļŖö ĻĄ¼ņåŹļÉ£ ņśüņŚŁņØ┤ ļ¦ÄņĢäņä£ ņāüļīĆņĀüņ£╝ļĪ£ ļ│ĆĒśĢļ¤ēņØ┤ ņĀüĻ▓ī ļ░£ņāØļÉ£ Ļ▓░Ļ│╝ļź╝ ļ│┤ņŚ¼ ņŻ╝Ļ│Ā ņ׳ļŗż.

Fig.┬Ā9

Displacement distribution on the blade (Case III, unit ╬╝m)

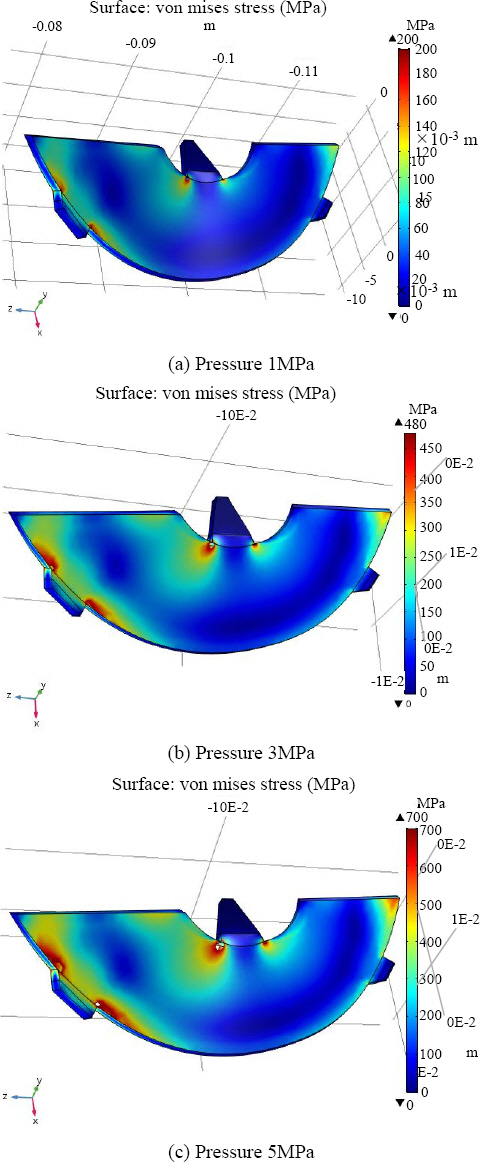

4. Ļ▓░Ļ│╝ ļČäņäØ ļ░Å Ļ│Āņ░░

ņĀæĒĢ®ļČĆļČäņŚÉ ļö░ļźĖ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØä ņĖĪņĀĢĒĢ£ Ļ▓░Ļ│╝ļź╝

Table 2ņŚÉ ņĀĢļ”¼ ĒĢśņśĆļŗż. ņĀĢļ”¼ļÉ£ ļ░öņÖĆ Ļ░ÖņØ┤, Ļ░ĆĒĢ┤ņ¦ĆļŖö ņĢĢļĀźņØ┤ ņ”ØĻ░ĆĒĢĀņłśļĪØ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ ņśłņĖĪļÉ£ ļ░öņÖĆ Ļ░ÖņØ┤ ņĀÉņ¦äņĀüņ£╝ļĪ£ ņ”ØĻ░ĆĻ░Ć ĒĢśņśĆļŗż. ļÅÖņØ╝ ņĢĢļĀźņŚÉņä£ļŖö Case I (ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁ Ļ│ĀņĀĢ) ļ│┤ļŗżļŖö Case III (ļĖöļĀłņØ┤ļō£ ņāüĒĢśļČĆ ĒāŁ Ļ│ĀņĀĢ)ņŚÉņä£ ļ│ĆĒśĢļ¤ēņØ┤ ņøöļō▒ņØ┤ Ļ░ÉņåīļÉ©ņØä ņĢī ņłś ņ׳ņŚłļŖöļŹ░, ņØ┤ļŖö ņÖĖĒīöļ│┤ ĒśĢĒā£ļ│┤ļŗżļŖö ņ¢æļŗ©ņ¦Ćņ¦Ć ĒśĢĒā£ļĪ£ Ļ│ĀņĀĢļÉśļŖö Ļ▓āņØ┤ ļ│ĆĒśĢļ¤ē Ļ┤ĆņĀÉņŚÉņä£ļŖö Ēø©ņö¼ ņ£Āļ”¼ĒĢ©ņŚÉņä£ ĻĖ░ņØĖĒĢ£ļŗż.

Table┬Ā2

|

Case study (Applied pressure) |

Max. disp. (╬╝m) |

|

Case I |

1 MPa |

52 |

|

3 MPa |

156 |

|

5 MPa |

260 |

|

Case II |

1 MPa |

45 |

|

3 MPa |

135 |

|

5 MPa |

224 |

|

Case III |

1 MPa |

45 |

|

3 MPa |

99 |

|

5 MPa |

164 |

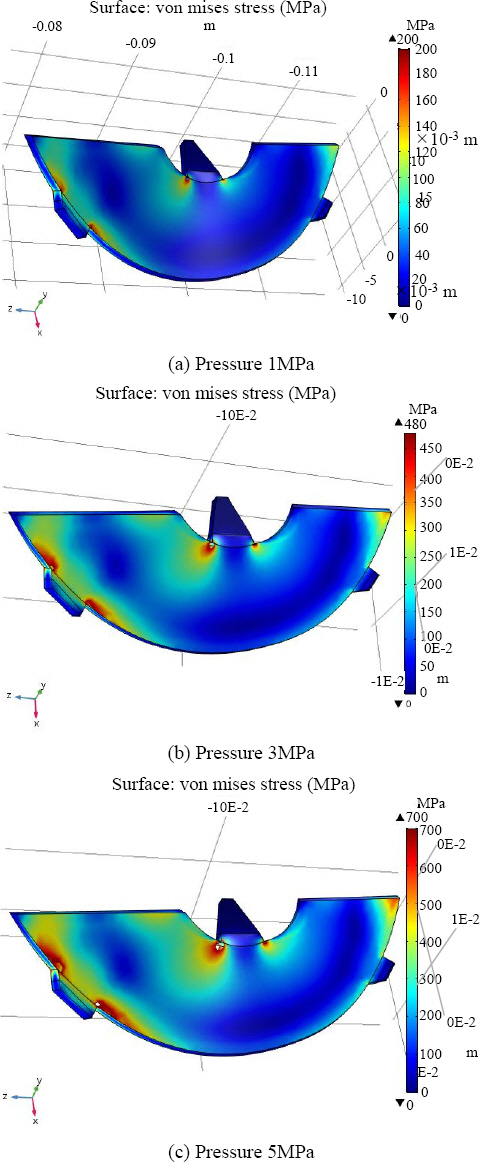

ļĖöļĀłņØ┤ļō£ ņĀæĒĢ®ļČĆļČäņŚÉ ļö░ļźĖ ņĄ£ļīĆņØæļĀźņØä ņĖĪņĀĢĒĢ£ Ļ▓░Ļ│╝ņŚÉņä£ļŖö ļ░śļīĆņØś Ļ▓ĮĒ¢źņØä ļ│┤ņśĆļŗż. ņ”ē, Case IņŚÉņä£ 1MPaļź╝ Ļ░ĆĒĢĀ ņŗ£ ņĄ£ļīĆņØæļĀźņØĆ 250MPa ļé┤ņÖĖ ņśĆņ£╝ļéś, Case IIņŚÉņä£ 1MPaņØä Ļ░ĆĒĢśņśĆņØä ņŗ£ņŚÉļŖö ņĄ£ļīĆņØæļĀźņØ┤ Ēīīļŗ©Ļ░ĢļÅä ņØ┤ņāüņØś ņØæļĀźļČäĒżļź╝ ļ│┤ņśĆļŗż. ĒŖ╣Ē׳ ņĄ£ļīĆņØæļĀźņØ┤ ļČäĒżĒĢ£ ņ¦ĆņĀÉņØĆ ņśłņĖĪļÉ£ ļ░öņÖĆ Ļ░ÖņØ┤ ĻĄ¼ņåŹļÉ£ ļĖöļĀłņØ┤ļō£ ņāüļČĆ ĒāŁĻ│╝ ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁņŚÉņä£ ļ░£ņāØņØ┤ ļÉśņŚłļŗż. ņØ┤ļŖö ļĖöļĀłņØ┤ļō£ņŚÉ ņĢĢļĀźņØ┤ Ļ░ĆĒĢ┤ņ¦ł ļĢīņŚÉ ĻĄ¼ņåŹļÉśņ¦Ć ņĢŖņØĆ ļĖöļĀłņØ┤ļō£ ĒāŁ ļČĆņ£äņØś ļ│ĆĒśĢņ£╝ļĪ£ ņØĖĒĢ┤ņä£ ņØæļĀźņØ┤ ņĀĆĻ░É ļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż. ļśÉĒĢ£,

Fig. 6ņŚÉņä£ ļéśĒāĆļéĖ ļ░öņÖĆ Ļ░ÖņØ┤ ņāüļČĆ ļĖöļĀłņØ┤ļō£ ĒāŁ ņŻ╝ņ£äļĪ£ ņĄ£ļīĆņØæļĀźņØ┤ ļ░£ņāØļÉśņŚłņ£╝ļ®░, ņØ┤ļŖö ĒĢśļČĆņØś 2Ļ░£ņØś ļĖöļĀłņØ┤ļō£ ĒāŁļ│┤ļŗż ņāüļČĆ 1Ļ░£ņØś ļĖöļĀłņØ┤ļō£ ĒāŁņŚÉ ņāüļīĆņĀüņ£╝ļĪ£ ĒĢśņżæņØ┤ ļ¦ÄņØ┤ Ļ░ĆĒĢ┤ņ¦ĆĻ▓ī ļÉśļŖö ĻĄ¼ņĪ░ņÖĆ ļŹöļČłņ¢┤ ņĮöļäłļČĆņØś ĒśĢņāüņŚÉ ņØæļĀźņ¦æņżæ ĒśäņāüņØ┤ ļ░£ņāØļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

5. Ļ▓░ ļĪĀ

ļ│Ė ļģ╝ļ¼ĖņŚÉņä£ļŖö Ļ│ĀņåŹ ĒÜīņĀäņÜ® ņ×äĒÄĀļØ╝ ļĖöļĀłņØ┤ļō£ļź╝ ļĀłņØ┤ņĀĆ ņÜ®ņĀæņŗ£ ļ░£ņāØĒĢśļŖö ņØæļĀźļČäĒż ļ░Å ļ│ĆĒśĢļ¤ē ņśłņĖĪņŚÉ ļīĆĒĢ£ ņ£ĀĒĢ£ņÜöņåī ĒĢ┤ņäØ Ļ▓░Ļ│╝ļź╝ ļČäņäØĒĢśņśĆļŗż. ņ£ĀĒĢ£ņÜöņåīļŖö ļĖöļĀłņØ┤ļō£ ĒĢśļČĆ ĒāŁ Ļ│ĀņĀĢ(Case I), ĒĢśļČĆ ņĀä ņśüņŚŁ Ļ│ĀņĀĢ(Case II), ņāüļČĆ ļ░Å ĒĢśļČĆ ĒāŁ ņśüņŚŁ Ļ│ĀņĀĢ(Case III) ĒĢśļŖö ņäĖ Ļ░Ćņ¦Ć Ļ▓ĮņÜ░ļź╝ ļČäņäØ ĒĢśņśĆļŗż.

Ļ░üĻ░üņØś Ļ▓ĮņÜ░ļ│äļĪ£ ļ│ĆĒśĢļ¤ēņØä ņĢīņĢäļ│┤ļ®┤, 1MPaņØś ņĢĢļĀźņŚÉņä£ļŖö ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ 45╬╝m ~ 52╬╝m ļé┤ņÖĖĻ░Ć ļ░£ņāØ ĒĢśņśĆĻ│Ā, ņĢĢļĀźņØ┤ 3MPaņÖĆ 5MPaļĪ£ ņāüņŖ╣ņŗ£ņŚÉ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ Ļ░üĻ░ü 99╬╝m ~ 156╬╝m Ļ│╝ 164╬╝m ~ 260╬╝mņØś ļ│ĆĒśĢļ¤ēņØ┤ ļ░£ņāØ ĒĢśņśĆļŗż.

ņĀäļ░śņĀüņ£╝ļĪ£ Ļ░ĆĒĢ┤ņ¦ĆļŖö ņĢĢļĀźņØ┤ ņ”ØĻ░ĆĒĢĀņłśļĪØ ņĄ£ļīĆ ļ│ĆĒśĢļ¤ēņØĆ ņĀÉņ¦äņĀüņ£╝ļĪ£ ņ”ØĻ░Ć ļÉśņŚłņ£╝ļ®░, ļÅÖņØ╝ ņĢĢļĀźņŚÉņä£ļŖö ĻĄ¼ņåŹļČĆņ£äĻ░Ć ļ¦ÄņØĆ Case IIIņØś ļ│ĆĒśĢļ¤ēņØ┤ ņøöļō▒ņØ┤ Ļ░ÉņåīļÉ©ņØä ņĢī ņłś ņ׳ņŚłļŗż. ļ░śļ®┤, ļĖöļĀłņØ┤ļō£ ņĀæĒĢ®ļČĆļČäņŚÉ ļö░ļźĖ ņĄ£ļīĆņØæļĀźņØä ņĖĪņĀĢĒĢ£ Ļ▓░Ļ│╝ņŚÉņä£ļŖö ļ░śļīĆņØś Ļ▓ĮĒ¢źņØä ļ│┤ņśĆļŖöļŹ░, ĻĄ¼ņåŹļČĆļČäņØ┤ ļ¦ÄņØĆ Case IIIņŚÉņä£ņØś ņØæļĀźņØ┤ Case I ļ│┤ļŗż ņøöļō▒Ē׳ļåÆņĢśļŗż. ņØ┤ļŖö ļĖöļĀłņØ┤ļō£ņŚÉ ņĢĢļĀźņØ┤ Ļ░ĆĒĢ┤ņ¦ł ļĢīņŚÉ ĻĄ¼ņåŹļÉśņ¦Ć ņĢŖņØĆ ļĖöļĀłņØ┤ļō£ ĒāŁ ļČĆņ£äņØś ļ│ĆĒśĢņ£╝ļĪ£ ņØĖĒĢ┤ņä£ ņØæļĀźņØ┤ ņĀĆĻ░É ļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

ļśÉĒĢ£, ĒāŁ ņŻ╝ņ£äļĪ£ ņĄ£ļīĆņØæļĀźņØ┤ ļ░£ņāØļÉśņŚłļŖöļŹ░, ĒĢśļČĆ 2Ļ░£ņØś ļĖöļĀłņØ┤ļō£ ĒāŁļ│┤ļŗż ņāüļČĆ 1Ļ░£ņØś ļĖöļĀłņØ┤ļō£ ĒāŁņŚÉ ņāüļīĆņĀüņ£╝ļĪ£ ĒĢśņżæņØ┤ ļ¦ÄņØ┤ Ļ░ĆĒĢ┤ņ¦ĆĻ▓ī ļÉśļŖö ĻĄ¼ņĪ░ņÖĆ ļŹöļČłņ¢┤ ņĮöļäłļČĆņØś ĒśĢņāüņŚÉ ņØæļĀźņ¦æņżæ ĒśäņāüņØ┤ ļ░£ņāØļÉ£ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ĒĢśņśĆļŗż.

Ļ▓░Ļ│╝ņĀüņ£╝ļĪ£ ņØæļĀźĻ│╝ ļ│ĆĒśĢļ¤ēņØĆ ļ░śļ╣äļĪĆ Ļ┤ĆĻ│äņŚÉ ņ׳ļŖöļŹ░, ņØ┤ļź╝ Ļ│ĀļĀżĒĢ£ ņÜ®ņĀæļČĆ ņäżĻ│äĻ░Ć ĒĢäņÜöĒĢśļ®░, ņ£ĀĒĢ£ņÜöņåīļ▓ĢņØä ņé¼ņÜ®ĒĢśņŚ¼ņä£ ņØæļĀźņØ┤ ņ¦æņżæņØ┤ ļÉśļŖö ļČĆļČäņØś ĒśĢņāüņØä ņĄ£ņĀüĒÖö ĒĢśņŚ¼ ņØæļĀźĻ│╝ ļ│ĆĒśĢļ¤ēņØä ņĄ£ņåīĒÖö ĒĢĀ ņłś ņ׳ļŖö ļĖöļĀłņØ┤ļō£ ņäżĻ│ä ļ░Å ļĀłņØ┤ņĀĆ ņÜ®ņĀæļČĆ ņäżĻ│äĻ░Ć ĒĢäņÜöĒĢĀ Ļ▓āņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

ņ£ĀĒĢ£ņÜöņåī ĒĢ┤ņäØĻ▓░Ļ│╝ņØś ņŗĀļó░ņä▒ņØä Ļ▓Ćņ”ØĒĢśĻĖ░ ņ£äĒĢ┤ņä£ļŖö ņŗżņĀ£ ņÜ®ņĀæĒÆłņØś ņŗżĒŚśņĀü Ļ▓░Ļ│╝ņÖĆ ļ╣äĻĄÉļź╝ ĒĢśņŚ¼ņĢ╝ ĒĢśņ¦Ćļ¦ī, ļ░Ćļ┤ēļÉ£ ņÜ®ņĀæļČĆ ņ£äņ╣śņØś ņĀ£ĒĢ£ ļ░Å ņÜ®ņĀæļČĆ Ļ░ĢļÅäņĖĪņĀĢņØś ņ¢┤ļĀżņøĆņØ┤ ņ׳ņ¢┤ņä£ ņłśĒ¢ēņØ┤ ļÉśņ¦Ć ļ¬╗ĒĢśņśĆļŗż. Ē¢źĒøä ņØ┤ļ¤¼ĒĢ£ ļČĆļČäņØ┤ ņóĆļŹö ļ│┤ņÖäļÉśļ®┤ ņÜ®ņĀæļČĆ ņäżĻ│äļź╝ ņ£äĒĢ£ ļ╣äņÜ®ņĀłĻ░É ļ░Å ņŗĀļó░ļÅä ĒĢŁņāüņØ┤ ņØ┤ļŻ©ņ¢┤ ņ¦ł Ļ▓āņ£╝ļĪ£ ĻĖ░ļīĆĻ░Ć ļÉ£ļŗż.

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print