1. ņä£ ļĪĀ

718ĒĢ®ĻĖłņØĆ ņÜ░ņłśĒĢ£ Ļ│Āņś©Ļ░ĢļÅäņÖĆ ļé┤ļČĆņŗØņä▒ņ£╝ļĪ£ ņØĖĒĢ┤ ņé░ņŚģĻ│äņŚÉ ļäÉļ”¼ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ļŖö NiĻĖ░ ņ┤łļé┤ņŚ┤ĒĢ®ĻĖłņØ┤ļŗż

1,2). ĻĘĖļ¤¼ļéś, ņĄ£ĻĘ╝ ļōżņ¢┤ ĻĖēļō▒ĒĢ£ Ni ņøÉņåīņ×¼ņØś Ļ░ĆĻ▓® ļĢīļ¼ĖņŚÉ ņé░ņŚģĻ│äņŚÉņä£ ļīĆļ¤ēņé¼ņÜ®ņØĆ ņĀ£ĒĢ£ņĀüņ£╝ļĪ£ ņØ┤ļŻ©ņ¢┤ņ¦ĆĻ│Ā ņ׳ļŗż

3). ĻĘ╝ļלļŖö ņ┤łļé┤ņŚ┤ ĒĢ®ĻĖłņØś ņØ╝ļČĆļź╝ ņāüļīĆņĀüņ£╝ļĪ£ ņĀĆļĀ┤ĒĢ£ ĒĢ®ĻĖłĻ░Ģņ£╝ļĪ£ ļīĆņ▓┤ĒĢśĻ▒░ļéś ņé¼ņÜ®ļ¤ēņØä ņżäņØ┤ļĀżļŖö ņŗ£ļÅäĻ░Ć ņØ┤ļŻ©ņ¢┤ņ¦ĆĻ│Ā ņ׳ļŗż

4-6). ĒŖ╣Ē׳, 718ĒĢ®ĻĖłĻ│╝ ļé┤ņŚ┤Ļ░ĢņØä ņÜ®ņĀæ┬ĘņĀæĒĢ®ĒĢśņŚ¼ ņé¼ņÜ®ĒĢśļĀżļŖö ņŗ£ļÅäĻ░Ć ĒÖ£ļ░£Ē׳ ņØ┤ļŻ©ņ¢┤ņ¦ĆĻ│Ā ņ׳ļŗż. ņØ╝ļ░śņĀüņØĖ ļé┤ņŚ┤ĒĢ®ĻĖłņØś ņÜ®ņĀæ ļ░®ļ▓ĢņØĆ ĒÖĢņé░ņĀæĒĢ®, ņĀäņ×Éļ╣öņÜ®ņĀæ, ļĖīļĀłņØ┤ņ¦Ģ, ļ¦łņ░░ ņÜ®ņĀæ ļō▒ņØ┤ ņ׳ļŗż

7). ļĖīļĀłņØ┤ņ¦ĢņØĆ ĒåĄņāüņĀüņ£╝ļĪ£ ļé«ņØĆ Ēü¼ļ”ĮĻ░ĢļÅäļź╝ ņ£Āļ░£ĒĢśļ®░, ĒÖĢņé░ ņÜ®ņĀæņØĆ Al, Ti ņøÉņåīņØś ņé░ĒÖö ļśÉļŖö ĒÄĖņäØņØ┤ ļ¼ĖņĀ£Ļ░Ć ļÉ£ļŗż

8,9). ņĀäņ×Éļ╣ö ņÜ®ņĀæņØĆ ĒŖ╣ņä▒ņØ┤ ņÜ░ņłśĒĢśļéś ņ¦äĻ│Ą ļČäņ£äĻĖ░ ņĀ£ņ¢┤ļź╝ ņ£äĒĢ£ ļŗ©Ļ░Ć ņāüņŖ╣ ļ¼ĖņĀ£Ļ░Ć ņ׳ļŗż. ĒĢ£ĒÄĖ, ļ¦łņ░░ ņÜ®ņĀæņØĆ ļŗżļźĖ ĻĖłņåŹņØä ņĀæĒĢ® ĒĢĀ ļĢī Ļ░Ćņן Ļ▓ĮņĀ£ņĀüņØ┤ļ®░ ļåÆņØĆ ņāØņé░ņä▒ņØä ļ│┤ņØ┤ļŖö ņןņĀÉņØ┤ ņ׳ļŗż

10). ļ¦łņ░░ņÜ®ņĀæņŚÉņä£ļŖö ņĢĢļĀźĒĢśņŚÉņä£ ĒÜīņĀäĒĢśļŖö ĻĖ░Ļ│äņĀü ņŚÉļäłņ¦ĆĻ░Ć ļ¦łņ░░ņØä ĒåĄĒĢ┤ ņŚ┤ņŚÉļäłņ¦ĆļĪ£ ļ│ĆĒÖśļÉśņ¢┤ ĻĖłņåŹņØä Ļ▓░ĒĢ®ņŗ£ĒéżļŖö ņŚÉļäłņ¦ĆļĪ£ ņé¼ņÜ®ļÉ£ļŗż. 718ĒĢ®ĻĖłĻ│╝ ņŖżĒģīņØĖļ”¼ņŖżĻ░ĢņØś ļ¦łņ░░ņÜ®ņĀæņØĆ ņŚ¼ļ¤¼ ņŚ░ĻĄ¼ņ×ÉņŚÉņä£ ņŚ░ĻĄ¼ļÉ£ ļ░öĻ░Ć ņ׳ļŖöļŹ░ ļ¦ÄņØĆ Ļ│ĄņĀĢ ļ│ĆņłśĻ░Ć ļ»ĖņäĖņĪ░ņ¦ü ļ░Å ņĀæĒĢ®Ļ░ĢļÅäņŚÉ ņśüĒ¢źņØä ļ»Ėņ╣śļŖö Ļ▓āņ£╝ļĪ£ ļ│┤Ļ│ĀļÉśĻ│Ā ņ׳ļŗż

11). ņŻ╝ņÜö ļ¦łņ░░ņÜ®ņĀæņØś Ļ│ĄņĀĢļ│ĆņłśļŖö ļ¦łņ░░ņŗ£Ļ░ä, ļ¦łņ░░ņĢĢļĀź, ņŗ£Ļ░ä, ņĢĢļĀź, ĒÜīņĀä ņåŹļÅä, ĻĘĖļ”¼Ļ│Ā ĒøäņŚ┤ņ▓śļ”¼ (post- weld heat-treatment, PWHT)ļō▒ņØ┤ļŗż. ĻĖ░ņĪ┤ņØś ņŚ░ĻĄ¼ņŚÉņä£ļŖö ļ¦łņ░░ņÜ®ņĀæņØä ņ£äĒĢ£ ĻĖ░ļ│ĖņĀüņØĖ Ļ│ĄņĀĢļ│Ćņłś ĒÜ©Ļ│╝ ļ░Å ņØ┤ņŚÉ ļö░ļźĖ ņĀæĒĢ®Ļ░ĢļÅäņŚÉ ļīĆĒĢ£ ņŚ░ĻĄ¼Ļ░Ć ņŻ╝ļź╝ ņØ┤ļŻ©ņŚłļŗż. ĻĘĖļ¤¼ļéś, PWHTņØś ĒÜ©Ļ│╝ņŚÉ ļīĆĒĢ£ ļ»ĖņäĖņĪ░ņ¦ü ļ░Å ĻĖ░Ļ│äņĀü ļ¼╝ņä▒ņØś ļ│ĆĒÖöļŖö ņĢäņ¦ü ņŚ░ĻĄ¼Ļ░Ć ļČĆņĪ▒ĒĢ£ ņāüĒÖ®ņØ┤ļŗż. ļ│Ė ņŚ░ĻĄ¼ņŚÉņä£ļŖö ņŚ¼ļ¤¼ ņś©ļÅäņŚÉņä£ PWHTļź╝ ņłśĒ¢ēĒĢśņśĆĻ│Ā ĻĘĖ Ēøä ņĀæĒĢ®ļČĆņØś Ļ▓ĮļÅä, ņØĖņןĒŖ╣ņä▒, ņ×öļźśņØæļĀź ņĖĪņĀĢ ņŗ£ĒŚśņØä ĒĢśņśĆļŗż. ņ¢╗ņ¢┤ņ¦ä ĻĖ░Ļ│äņĀü ĒŖ╣ņä▒ ĒÅēĻ░ĆĻ▓░Ļ│╝ļź╝ ļ»ĖņäĖņĪ░ņ¦ü ļ│ĆĒÖöņÖĆ ļ╣äĻĄÉĒĢśņŚ¼ ĒĢ┤ņäØĒĢśņśĆļŗż.

2. ņŗżĒŚśļ░®ļ▓Ģ

ļ¦łņ░░ņÜ®ņĀæņŗ£ĒŚśņØä ņłśĒ¢ēĒĢśĻĖ░ ņ£äĒĢ┤ TOHO (TH25) Break- typeņØś ņåīĒśĢļ¦łņ░░ņĢĢņĀæĻĖ░ ņןļ╣äļź╝ ņé¼ņÜ®ĒĢśņśĆļŗż. 718ĒĢ®ĻĖłĻ│╝ SNCRWĻ░ĢņØś ņ¦üĻ▓Į 20 mmņØś ņøÉĒåĄĒśĢ ņŗ£ĒÄĖņØä ņé¼ņÜ®ĒĢśņŚ¼ ņØ┤ņóģ ļ¦łņ░░ņÜ®ņĀæņØä ņłśĒ¢ēĒĢśņśĆļŗż. ļ¦łņ░░ņĢĢņĀæ Ļ│ĄņĀĢņĪ░Ļ▒┤ņØĆ ĒÜīņĀäņłś 150 RPM, ļ░£ņŚ┤ņĢĢļĀźņØĆ 35 MPa, ļ░£ņŚ┤ņŗ£Ļ░ä 40 sec, ņŚģņģŗņĢĢļĀź 100 MPa, ņŚģņģŗņŗ£Ļ░äņØĆ 5 secņśĆļŗż. 718ĒĢ®ĻĖł ļ░Å SNCRWņØś ĒÖöĒĢÖ ņĪ░ņä▒ņØä

Table 1ņŚÉ ļéśĒāĆļé┤ņŚłļŗż. 718ĒĢ®ĻĖłņØĆ ļ¦łņ░░ņÜ®ņĀæ ņĀäņŚÉ 1000 ┬░CņŚÉņä£ 2 ņŗ£Ļ░ä ļÅÖņĢł ņÜ®ņ▓┤ĒÖöņ▓śļ”¼ ĒĢśņśĆļŗż. ņŗ£ĒŚśĒÄĖņØĆ ņ¦üĻ▓Į 20 mm, ĻĖĖņØ┤ 100 mmņØś ĒÖśļ┤ēņ£╝ļĪ£ Ļ░ĆĻ│ĄĒĢśņśĆļŗż. ļ¦łņ░░ņÜ®ņĀæ Ēøä ņŗ£ĒÄĖņØĆ 500, 720, 900 ┬░CņŚÉņä£ 8ņŗ£Ļ░ä PWHT ņ▓śļ”¼ Ēøä Ļ│ĄļāēĒĢśņśĆļŗż. ĻĘĖ Ēøä ĻĖ░Ļ│äĻ░ĆĻ│ĄņØä ĒåĄĒĢ┤ Ēöīļלņē¼Ļ░Ć ņĀ£Ļ▒░ļÉ£ ņŗ£ĒÄĖņŚÉņä£ Ļ▓ĮļÅä ļ░Å ņØĖņןņŗ£ĒŚśņÜ® ņŗ£ĒÄĖļōżņØ┤ ņ▒äņĘ©ļÉśņŚłļŗż. PWHT ņ▓śļ”¼ ņĀä┬ĘĒøä Ļ▓ĮļÅäņŗ£ĒŚśņØĆ ņĢĢņ×ģņ×Éļź╝ 1 ŃÄÅņØś ĒĢśņżæņ£╝ļĪ£ 1 mm Ļ░äĻ▓®ņ£╝ļĪ£ 10 ņ┤ł ļÅÖņĢł Ļ░ĆņĢĢĒĢśņŚ¼ ņłśĒ¢ēĒĢśņśĆļŗż. ņØĖņןņŗ£ĒŚś ĒÄĖņØś Ļ▓īņØ┤ņ¦Ć ĻĖĖņØ┤ļŖö 25 mmņØ┤Ļ│Ā, ņØĖņןņŗ£ĒŚśņØĆ Ēü¼ļĪ£ņŖż ĒŚżļō£ ņåŹļÅä 2.5 mm/min ņĪ░Ļ▒┤ņ£╝ļĪ£ ņłśĒ¢ēļÉśņŚłļŗż. ļśÉĒĢ£, ņŚ┤ņ▓śļ”¼ ņĀä┬ĘĒøäļĪ£ ņāüļČäņäØņØä ņ£äĒĢśņŚ¼ Rigaku ņןļ╣äļź╝ ņØ┤ņÜ®ĒĢśņŚ¼ XRD ļČäņäØņØ┤ ņłśĒ¢ēļÉśņŚłļŗż. ņ×öļźś ņØæļĀźĒÅēĻ░ĆļŖö ļéśļģĖņĢĢņ×ģļ▓Ģņ£╝ļĪ£ ņłśĒ¢ēļÉśņŚłņ£╝ļ®░ Fronticsņé¼ņØś ņןļ╣äļź╝ ņé¼ņÜ®ĒĢśņśĆļŗż. ļéśļģĖ ņĢĢņ×ģņŗ£ĒŚśņÜ® Ēæ£ņżĆņŗ£ĒÄĖ ņĀ£ņ×æņØä ņ£äĒĢ┤ 718ĒĢ®ĻĖł ļ░Å SNCRWĒĢ®ĻĖłņØä 1000┬░CņŚÉņä£ 24ņŗ£Ļ░ä ņ¢┤ļŗÉļ¦ü ĒĢśņśĆĻ│Ā ņØ┤ ņŗ£ĒÄĖļōżņØĆ ņ×öļźĀņØæļĀźņØ┤ ņĀ£Ļ▒░ļÉ£ ņāüĒā£ļØ╝Ļ│Ā Ļ░ĆņĀĢĒĢśņśĆļŗż.

Table┬Ā1

Chemical compositions of Alloy 718 and SNCRW (wt.%)

|

Material |

Cr |

Fe |

Mo |

Al |

Si |

Mn |

Ti |

C |

Ni |

|

Alloy 718 |

19.0 |

17.8 |

2.8 |

0.62 |

0.1 |

0.06 |

1.1 |

- |

Bal. |

|

SNCRW |

19.9 |

68.5 |

- |

0.01 |

1.4 |

0.8 |

0.01 |

0.2 |

9.2 |

3. Ļ▓░Ļ│╝ ļ░Å ĒåĀņØś

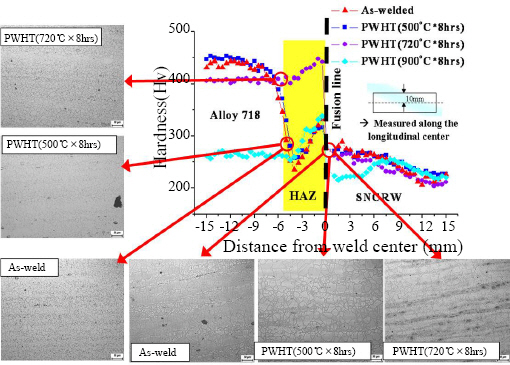

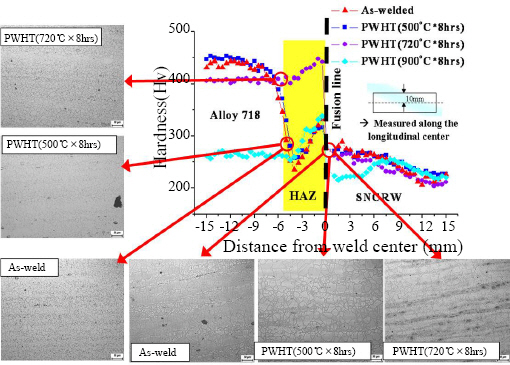

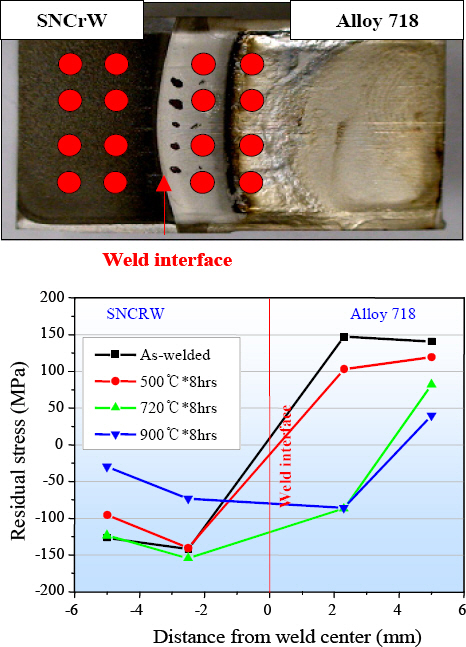

Fig. 1ņØĆ 718ĒĢ®ĻĖłĻ│╝ SNCRWņØś ļ¦łņ░░ņĀæĒĢ® ĒøäņØś ņŗ£ĒÄĖņØś Ļ▒░ņŗ£ņĀü ĻĄ¼ņĪ░ļź╝ ļ│┤ņŚ¼ņżĆļŗż. ļ¦łņ░░ņĀæĒĢ® ņŗ£ĒÄĖņØś ĒśĢņāüņØĆ 718ĒĢ®ĻĖłņØ┤ SNCRWļ│┤ļŗż ļåÆņØĆ Ļ░ĢļÅäļź╝ Ļ░Ćņ¦ĆĻĖ░ ļĢīļ¼ĖņŚÉ SNCRWļĪ£ ĻĄĮņ¢┤ņ¦ĆļŖö ĒśäņāüņØä ļ│┤ņśĆļŗż. SNCREWļČĆļČäņØś Ēöīļלņē¼ (Flash)ņŚÉņä£ļŖö ĻĘĀņŚ┤ņØ┤ ļ░£ņāØĒĢśņ¦Ć ņĢŖņØĆ ļ░śļ®┤ 718 ĒĢ®ĻĖłņ¬ĮņŚÉņä£ļŖö ĻĘĀņŚ┤ņØ┤ ļŗżņłś ļ░£ņāØĒĢśņśĆļŗż. ņØ┤Ļ▓āņØĆ 718ĒĢ®ĻĖłņØś Ļ░ĢļÅäĻ░Ć ļåÆņĢä ņåīņä▒ļ│ĆĒśĢņØ┤ ņ¢┤ļĀżņøĀĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

Fig. 2ļŖö ļ¦łņ░░ņĀæĒĢ® ņ¦üĒøä 718ĒĢ®ĻĖł ļ░Å SNCRWņØś ņ£äņ╣ś ļ│ä ļ»ĖņäĖņĪ░ņ¦ü ļ│ĆĒÖöļź╝ ļ│┤ņŚ¼ņŻ╝Ļ│Ā ņ׳ļŗż. 718ĒĢ®ĻĖł ļČĆļČäņØś Ļ▓ĮņÜ░ ņĀæĒĢ®ļČĆņŚÉņä£ ļ╣äĻĄÉņĀü ļ®Ćļ”¼ ļ¢©ņ¢┤ņ¦ä ļČĆņ£äļŖö Ļ▓░ņĀĢļ”ĮļÅäĻ░Ć ņāüļīĆņĀüņ£╝ļĪ£ Ēü¼Ļ│Ā Ļ▓░ņĀĢļ”ĮĻ│äļ®┤ņØ┤ ļ¦żņÜ░ ļČĆļō£ļ¤¼ņøĀļŗż. ļ░śļ®┤, ņĀæĒĢ®ļ®┤ņŚÉ Ļ░ĆĻ╣īņøī ņ¦łņłśļĪØ Ļ▓░ņĀĢļ”ĮļÅäĻ░Ć ļ»ĖņäĖĒĢ┤ņ¦ĆĻ│Ā ļ¼╝Ļ▓░(wavy)ĒśĢĒā£ņØś Ļ▓░ņĀĢļ”ĮĻ│äļ®┤ņØ┤ Ļ┤Ćņ░░ļÉśņŚłļŖöļŹ░ ņØ┤ļŖö ņĀäĒśĢņĀüņØĖ ļÅÖņĀüņ×¼Ļ▓░ņĀĢ ņĪ░ņ¦üņØś ĒŖ╣ņ¦ĢņØ┤ļŗż

12). ļ░śļ®┤, SNCREW ļČĆļČäņŚÉņä£ļŖö 718ĒĢ®ĻĖłņŚÉ ļ╣äĒĢ┤ ļÅÖņĀüņ×¼Ļ▓░ņĀĢņØ┤ ĒÖ£ļ░£ĒĢśĻ▓ī ļ░£ņāØĒĢśņ¦Ć ņĢŖņĢśļŗż.

Fig.┬Ā1

Appearance of friction welded Alloy 718 and SNCRW stainless steel specimens

Fig.┬Ā2

Optical images revealing the microstructure of Alloy 718 after friction welding

ļ¦łņ░░ņĀæĒĢ® Ēøä PWHTļź╝ 500, 720, 900 ┬░CņŚÉņä£ 8ņŗ£Ļ░ä ņłśĒ¢ēĒĢśņśĆĻ│Ā ņØ┤ņŚÉ ļö░ļźĖ Ļ▓ĮļÅäņØś ļ│ĆĒÖöļź╝ ņĖĪņĀĢĒĢśņśĆļŗż.

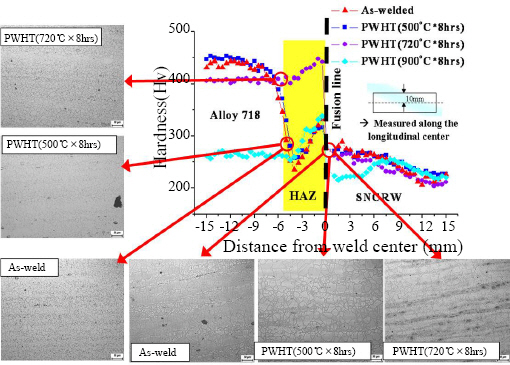

Fig. 3ņØĆ Ļ▓ĮļÅä ļ░Å ļČĆņ£äļ│ä ļ»ĖņäĖņĪ░ņ¦ü ļ│ĆĒÖöļź╝ ļ│┤ņŚ¼ņżĆļŗż. ņÜ®ņĀæ ņ¦üĒøä (as-welded)ņŚÉņä£ļŖö 718ĒĢ®ĻĖł ļ¬©ņ×¼ļČĆņØś Ļ▓ĮļÅäļŖö SNCRW ļ¬©ņ×¼ļČĆ ļ│┤ļŗż 200 Hv ņĀĢļÅä Ļ▓ĮļÅäĻ░Ć ļŹö ļåÆņĢśļŗż. ĻĘĖļ¤¼ļéś, 718ĒĢ®ĻĖłņŚÉ Ļ░ĆĻ╣īņÜ┤ ņŚ┤ņŚ┤Ē¢źļČĆ (heat affected zone, HAZ)ņŚÉņä£ļŖö Ļ▓ĮļÅäĻ░Ć ĻĖēĻ▓®Ē׳ ļé«ņĢäņĪīĻ│Ā ļŗżņŗ£ SNCRWņ¬Įņ£╝ļĪ£ ņØ┤ļÅÖĒĢśļ®┤ņä£ Ļ▓ĮļÅäĻ░Ć ņāüņŖ╣ĒĢśļŖö ļ¬©ņŖĄņØä ļ│┤ņŚ¼ņŻ╝ņŚłļŗż. ņØ┤ļŖö ļ¦łņ░░ņĀæĒĢ® Ēøä ļåÆņØĆ ļ¦łņ░░ņŚ┤ļĪ£ ņØĖĒĢ┤ ņŻ╝ņÜö Ļ░ĢĒÖöņāüņØĖ ╬│ŌĆ│ ņäØņČ£ņāüņØ┤ HAZņŚÉņä£ ņÜ®ĒĢ┤ļÉśņŚłĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ņé¼ļŻīļÉ£ļŗż

13). 500 ┬░C ņŚ┤ņ▓śļ”¼ĒĢ£ ņåīņ×¼ņØś Ļ▓ĮļÅäļŖö as-weld ņāüĒā£ņÖĆ ņ£Āņé¼ĒĢ£ Ļ▒░ļÅÖņØä ļ│┤ņśĆļŗż. ĒĢ£ĒÄĖ, 720 ┬░C ņŚ┤ņ▓śļ”¼ņØś Ļ▓ĮņÜ░ HAZņØś Ļ▓ĮļÅäĻ░Ć ĻĖēĻ▓®Ē׳ ņāüņŖ╣ĒĢśļŖö Ļ▓āņØä Ļ┤Ćņ░░ĒĢĀ ņłś ņ׳ņŚłļŗż. ņØ┤ļŖö ļ¦łņ░░ņĀæĒĢ® ņżæ ĻĖ░ņ¦ĆņŚÉ Ļ│ĀņÜ®ļÉśņŚłļŹś ╬│ŌĆ│ ņāüņØ┤ 720 ┬░CņŚÉņä£ ļŗżņŗ£ ņ×¼ņäØņČ£ļÉśņŚłĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ļ│┤ņØĖļŗż. ļ░śļ®┤, ņŚ┤ņ▓śļ”¼ ņś©ļÅäĻ░Ć ļŹö ļåÆņĢäņĀĖ 900 ┬░CĻ░Ć ļÉśļ®┤ HAZ ņÖĖņŚÉ 718ĒĢ®ĻĖłņØś ļ¬©ņ×¼ļČĆņŚÉņä£ļÅä Ļ▓ĮļÅäĻ░Ć Ēü¼Ļ▓ī ĒĢśļØĮĒĢśņśĆļŗż. ņØ┤ļŖö 900 ┬░C ņŚÉņä£ ╬│ŌĆ│ ņāüņØ┤ ņ×¼Ļ│ĀņÜ®ļÉśņŚłĻĖ░ ļĢīļ¼ĖņØ┤ļŗż

13). ĒĢ£ĒÄĖ, HAZ Ļ▓ĮĻ│äņ¬ĮņŚÉņä£ Ļ▓░ņĀĢļ”ĮļÅäļŖö ņŚ┤ņ▓śļ”¼ņŚÉ ļö░ļØ╝ Ēü¼Ļ▓ī ļ│ĆĒÖöĒĢśņ¦Ć ņĢŖņĢśļŗż. ņØ┤ļŖö Ļ▓ĮļÅäņØś ļ│ĆĒÖöĻ░Ć Ļ▓░ņĀĢļ”ĮĒü¼ĻĖ░ ļ│ĆĒÖö ļ│┤ļŗżļŖö Ļ░ĢĒÖöņāüņØś ņäØņČ£ ņŚ¼ļČĆņŚÉ Ēü¼Ļ▓ī Ļ┤ĆĻ│äļÉśņ¢┤ņ׳ņØīņØä ļ░śņ”ØĒĢ£ļŗż

14).

Fig.┬Ā3

Hardness value of Alloy 718 and SNCRW friction welded specimens after post-weld heat treatment

13)

720 ┬░C├Ś8ņŗ£Ļ░ä ņĪ░Ļ▒┤ņŚÉņä£ PWHTļÉ£ ņŗ£ĒÄĖņØś HAZ Ļ▓ĮļÅäņāüņŖ╣ņØ┤ ņøÉņØĖņØ┤ ╬│ŌĆ│ņāüņØś ņäØņČ£Ļ│╝ Ļ┤ĆļĀ©ņØ┤ ņ׳ļŖöņ¦Ć ĒÖĢņØĖĒĢśĻĖ░ ņ£äĒĢ┤ņä£ Ļ░ü ņŗ£ĒÄĖļ¦łļŗż XRD ļČäņäØņØä ņłśĒ¢ēĒĢśņśĆļŗż.

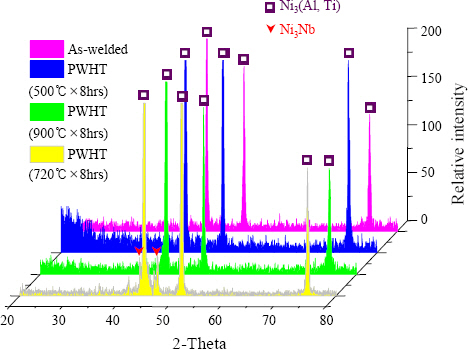

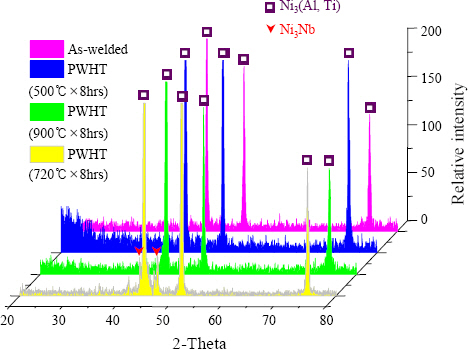

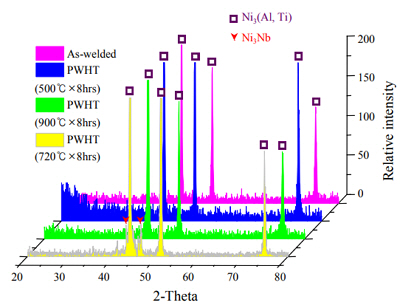

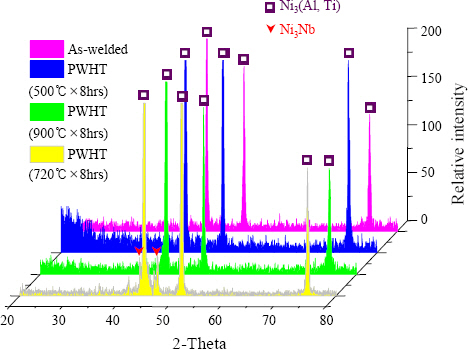

Fig. 4ļŖö Ļ░ü ņŗ£ĒÄĖņŚÉņä£ XRD ļČäņäØĒĢ£ Ļ▓░Ļ│╝ļź╝ ļéśĒāĆļé┤ņŚłļŗż. Ļ│ĄĒåĄņĀüņ£╝ļĪ£ ļ¬©ļōĀ ņŗ£ĒÄĖņŚÉņä£ ╬│ņāüņØĖ Ni

3(Al, Ti)Ļ░Ć Ļ┤Ćņ░░ļÉśņŚłļŗż. ĻĘĖļ¤¼ļéś, ņŻ╝Ļ░ĢĒÖöņāüņØĖ ╬│ŌĆ│(Ni

3Nb)ļŖö 720 ┬░C├Ś8ņŗ£Ļ░ä ņĪ░Ļ▒┤ņŚÉņä£ļ¦ī Ļ┤Ćņ░░ļÉśņŚłļŗż. ļö░ļØ╝ņä£ 720┬░C├Ś8ņŗ£Ļ░äņØś ņĪ░Ļ▒┤ņŚÉņä£ņØś Ļ▓ĮļÅäņāüņŖ╣ņØĆ ╬│ŌĆ│ņāüņØś ņ×¼ņäØņČ£ņØ┤ ņøÉņØĖņ×äņØä ņĢī ņłś ņ׳ņŚłļŗż.

Fig.┬Ā4

XRD patterns of Alloy 718 and SNCRW friction welded specimens after post-weld heat treatment

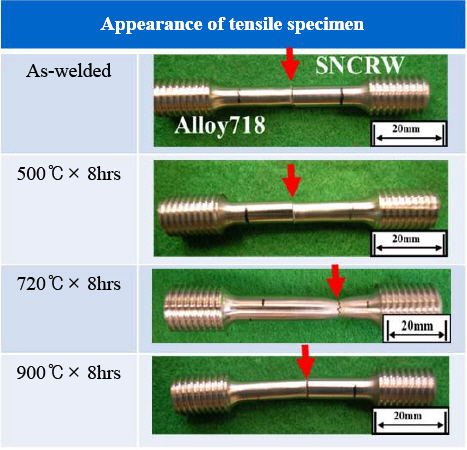

Fig. 5ļŖö PWHT ĒÜ©Ļ│╝ņŚÉ ļö░ļźĖ ņāüņś©ņØĖņןņŗ£ĒŚśņØś Ļ▓░Ļ│╝ļź╝ ļ│┤ņŚ¼ņŻ╝ļŖö ņé¼ņ¦äņØ┤ļŗż. Ēīīļŗ©ņŗ£ĒÄĖ ņé¼ņ¦ä ņ£äņØś ĒÖöņé┤Ēæ£ļōżņØĆ ņØĖņן Ēøä Ēīīļŗ© ņ¦ĆņĀÉņØä ļéśĒāĆļéĖļŗż. As-weld ņÖĆ 500, 900 ┬░C PWHT ņĪ░Ļ▒┤ņŚÉņä£ļŖö ļ¬©ļæÉ ņÜ®ņĀæļČĆņŚÉņä£ Ēīīļŗ©ņØ┤ ņØ╝ņ¢┤ļé¼ļŗż. ĻĘĖļ¤¼ļéś, 720 ┬░C├Ś8ņŗ£Ļ░ä PWHT ņĪ░Ļ▒┤ņŚÉņä£ļŖö SNCRW ļ¬©ņ×¼ņŚÉņä£ Ēīīļŗ©ņØ┤ ņØ╝ņ¢┤ļé£ Ļ▓āņØä ĒÖĢņØĖĒĢĀ ņłś ņ׳ņŚłļŗż. ņØ┤ļŖö ņŚ┤ņ▓śļ”¼ ĒÜ©Ļ│╝ņŚÉ ņØśĒĢ┤ 718ĒĢ®ĻĖł ļ¬©ņ×¼ļČĆņÖĆ HAZ Ļ░ĢļÅäĻ░Ć Ēü¼Ļ▓ī ņāüņŖ╣ĒĢ£ ļ░śļ®┤ SNCRW ļ¬©ņ×¼ļČĆņØś Ļ░ĢļÅäļŖö ņŚ¼ņĀäĒ׳ ļé«ĻĖ░ ļĢīļ¼ĖņŚÉ ļéśĒāĆļé£ ĒśäņāüņØ┤ļŗż

15). ņØ┤ Ļ▓░Ļ│╝ļŖö ļ¦łņ░░ņÜ®ņĀæ Ēøä PWHTņ▓śļ”¼ņØś ĒĢäņÜöņä▒ņØä ļŗżņŗ£ ĒĢ£ļ▓ł ļ│┤ņŚ¼ņŻ╝ļŖö Ļ▓░Ļ│╝ņØ┤ļŗż.

Fig.┬Ā5

Macro photos showing the shape of Alloy 718 and SNCRW specimens after tensile testing

Fig. 6ļŖö ļ¦łņ░░ņÜ®ņĀæ Ēøä ņÜ®ņĀæĒøäņŚ┤ņ▓śļ”¼ ņĪ░Ļ▒┤ļ│äņŚÉ ļö░ļØ╝ ņ×öļźśņØæļĀźņØä ņĖĪņĀĢĒĢ£ Ļ░ÆņØä ļéśĒāĆļé┤ņŚłļŗż. SNCRW ņśüņŚŁņŚÉņä£ ņĢĢņČĢņ×öļźśņØæļĀźņØ┤ Ļ┤Ćņ░░ļÉśĻ│Ā, 718ĒĢ®ĻĖł ņśüņŚŁņŚÉņä£ļŖö ņØĖņןņ×öļźśņØæļĀźņØ┤ Ļ┤Ćņ░░ļÉśņŚłļŗż. ņØ┤ļŖö 718ĒĢ®ĻĖłņØ┤ SNCRWļ│┤ļŗż ņāüļīĆņĀüņ£╝ļĪ£ ņĢäņŻ╝ ļåÆņØĆ Ļ░ĢļÅäļź╝ Ļ░Ćņ¦ĆĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ĒīÉļŗ©ļÉ£ļŗż

16). PWHTņś©ļÅäĻ░Ć ļåÆņØäņłśļĪØ ņ×öļźśņØæļĀźņØ┤ ņĀüņ¢┤ņ¦ÉņØä ĒÖĢņØĖĒĢĀ ņłś ņ׳ņŚłļŗż. 900┬░C├Ś8ņŗ£Ļ░ä ņĪ░Ļ▒┤ņŚÉņä£ Ļ░Ćņן ļé«ņØĆ ņ×öļźśņØæļĀźņØ┤ Ļ┤Ćņ░░ļÉśņŚłņ¦Ćļ¦ī ņĢ×ņŚÉņä£ ļ│┤ņØĖ Ļ▓░Ļ│╝ņÖĆ Ļ░ÖņØ┤ 900┬░C ├Ś8ņŗ£Ļ░ä ņĪ░Ļ▒┤ņŚÉņä£ļŖö ╬│ŌĆ│ņāüņØś ņ×¼Ļ│ĀņÜ®ņ£╝ļĪ£ Ļ▓ĮļÅäĻ░Ć ļ¦żņÜ░ ļé«ņĢśļŗż. ļö░ļØ╝ņä£, ļ╣äĻĄÉņĀü ņ×öļźśņØæļĀźņØ┤ ļé«Ļ│Ā ╬│═┤═┤ņāüņØś ņ×¼ņäØņČ£ ĒÜ©Ļ│╝ļź╝ ņ¢╗ņØä ņłś ņ׳ļŖö 720┬░C├Ś8ņŗ£Ļ░äņØś ņĪ░Ļ▒┤ņØ┤ ļ¦łņ░░ņÜ®ņĀæ PWHT ņĪ░Ļ▒┤ ņżæ Ļ░Ćņן ņĀüĒĢ®ĒĢ£ ņś©ļÅäļĪ£ ĒīÉļŗ©ļÉ£ļŗż.

Fig.┬Ā6

Distribution of residual stress of Alloy 718 and SNCRW friction welded specimens after post- weld heat treatment. Red dots indicate the position of measurement

4. Ļ▓░ ļĪĀ

718ĒĢ®ĻĖłĻ│╝ SNCRWĻ░ĢņØś ņØ┤ņóģ ļ¦łņ░░ņÜ®ņĀæņØä ņłśĒ¢ēĒĢśņśĆĻ│Ā, PWHTņŚÉ ļö░ļźĖ ļ»ĖņäĖņĪ░ņ¦ü ļ░Å ĻĖ░Ļ│äņĀüĒŖ╣ņä▒ ļ│ĆĒÖöļź╝ ņŚ░ĻĄ¼ĒĢśņŚ¼ ļŗżņØīĻ│╝ Ļ░ÖņØĆ Ļ▓░Ļ│╝ļź╝ ņ¢╗ņŚłļŗż.

1) 718ĒĢ®ĻĖłĻ│╝ SNCRWņØś ļ¦łņ░░ņĀæĒĢ®ļČĆļź╝ 720 ┬░C ņŚ┤ņ▓śļ”¼ĒĢ£ Ļ▓ĮņÜ░ ╬│ŌĆ│ņØś ņäØņČ£ļĪ£ ņØĖĒĢ┤ ļåÆņØĆ Ļ▓ĮļÅäĻ░Ć ņ¢╗ņ¢┤ņĪīļŗż. ļ░śļ®┤, PWHTĻ░Ć ņłśĒ¢ēļÉśņ¦Ć ņĢŖņĢśĻ▒░ļéś ņś©ļÅä ņĪ░Ļ▒┤ņØ┤ ļŗżļźĖ Ļ▓ĮņÜ░ ņāüļīĆņĀüņ£╝ļĪ£ ļé«ņØĆ Ļ▓ĮļÅäĻ░Ć ņ¢╗ņ¢┤ņĪīļŗż.

2) ļ¦łņ░░ņĀæĒĢ®ļČĆņØś ņ×öļźśņØæļĀźņØĆ 720 ┬░C ņØ┤ņāüņŚÉņä£ ņŚ┤ņ▓śļ”¼Ļ░Ć ņłśĒ¢ēļÉśņŚłņØä ļĢī ĒÜ©Ļ│╝ņĀüņ£╝ļĪ£ Ļ░ÉņåīļÉśņŚłļŗż.

3) PWHTĻ░Ć ņłśĒ¢ēļÉśņ¦Ć ņĢŖņĢśĻ▒░ļéś 500, 900 ┬░CņŚÉņä£ PWHTĻ░Ć ņłśĒ¢ēļÉ£ Ļ▓ĮņÜ░ ļ¦łņ░░ņÜ®ņĀæ ņŗ£ĒÄĖņØĆ ņÜ®ņĀæ ņØ┤ņØīļČĆņŚÉņä£ Ēīīļŗ©ļÉśņŚłļŗż. ļ░śļ®┤, 720 ┬░CņŚÉņä£ PWHTĻ░Ć ņłśĒ¢ēļÉ£ Ļ▓ĮņÜ░ SNCRW ļ¬©ņ×¼ ĻĖłņåŹņŚÉ ņØĖņן Ēīīļŗ©ņØ┤ ļ░£ņāØĒ¢łļŗż.