1. ņä£ ļĪĀ

Flux Cored Wire(ņØ┤ĒĢś FCW)ļŖö Flux Cored Arc Welding(ņØ┤ĒĢś FCAW)ņŚÉ ņé¼ņÜ®ļÉśļŖö ņÜ®ņĀæņ×¼ļŻīļĪ£ Covered Electrodeļź╝ ņé¼ņÜ®ĒĢśļŖö Shield Metal Arc Welding(ņØ┤ĒĢś SMAW)ņØä ļīĆņ▓┤ĒĢśĻĖ░ ņ£äĒĢ┤ 1953ļģä Arthur Bernard1)ņŚÉ ņØśĒĢ┤ Ļ░£ļ░£ ļÉśņ¢┤ Ēśäņ×¼ļŖö Ļ░Ćņן ļäÉļ”¼ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ļŖö ņÜ®ņĀæ ņ×¼ļŻīņØ┤ļŗż. ĒŖ£ļĖī(Tube) ļé┤ļČĆņŚÉ Ēöīļ¤ŁņŖż(Flux)ļź╝ ĒĢ©ņ£ĀĒĢśņŚ¼ ļ░śņ×ÉļÅÖ ļ░Å ņ×ÉļÅÖ ņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢśĻ│Ā ļåÆņØĆ ņāØņé░ņä▒Ļ│╝ ņØ┤ļÅÖņä▒ ļĢīļ¼ĖņŚÉ ļŗżņ¢æĒĢ£ ņé░ņŚģļČäņĢ╝ņŚÉ ņé¼ņÜ®ļÉ£ļŗż.

FCWņØś ņŚŁņé¼ļŖö ļŗ©Ļ│äņĀüņ£╝ļĪ£2) ņĄ£ņ┤ł ļīĆĻĄ¼Ļ▓Į(3.2mm)ņØ┤ ņŻ╝ļĪ£ ņé¼ņÜ®ļÉśņŚłņ£╝ļ®░, ņÜ®ņĀæņä▒Ļ│╝ ņĀüņÜ®ņä▒ņØś ļ¼ĖņĀ£ļĪ£ ņśżļ▓äļĀłņØ┤ ņÜ®ņĀæ(Overlay Welding)ļō▒ņØś ņØ╝ļČĆ ļČäņĢ╝ņŚÉ ņĀ£ĒĢ£ņĀüņ£╝ļĪ£ ņé¼ņÜ®ļÉśņŚłļŗż. ņØ┤Ēøä 1979ļģäļČĆĒä░ ņĀäņ×ÉņäĖļź╝ ņ£äĒĢ┤ ņŖ¼ļלĻĘĖ(Slag)ļź╝ ĒżĒĢ©ĒĢśļŖö ņåīĻĄ¼Ļ▓Į ņÖĆņØ┤ņ¢┤(1.2mm) Ļ░£ļ░£ļĪ£ ņé¼ņÜ®ļ¤ēņØ┤ Ēü¼Ļ▓ī ņ”ØĻ░ĆĒĢśĻĖ░ ņŗ£ņ×æĒ¢łļŗż. ņØ┤Ēøä ļ¦ÄņØĆ ņŚ░ĻĄ¼Ļ░Ć ņØ┤ļŻ©ņ¢┤ņĀĖ ļŗżņ¢æĒĢ£ ņŖ¼ļלĻĘĖ ĒāĆņ×ģņØś ņĀäņ×ÉņäĖņÜ® FCWņØś Ļ░£ļ░£ļĪ£ ņÜ®ņĀæ ņāØņé░Ļ│ĄņĀĢ ļ╣äņÜ®ņØä Ēü¼Ļ▓ī Ļ░Éņåīņŗ£Ēé¼ ņłś ņ׳ņ¢┤ ņĪ░ņäĀņé░ņŚģļČäņĢ╝ņŚÉ ņé¼ņÜ®ļ¤ēņØ┤ ņ”ØĻ░ĆļÉśņŚłĻ│Ā, ņÜ®ņĀæ ņāØņé░ ļ╣äņÜ® ņĀłĻ░ÉņŚÉ ņČ®ļČäĒ׳ ĻĖ░ņŚ¼ĒĢśĻ▓ī ļÉśņŚłļŗż.

ĒĢ£ĻĄŁņŚÉņä£ FCWņØś ņé¼ņÜ®ļ¤ēņØĆ ņ¦Ćļé£ 25ļģäĻ░ä ĻĖēĻ▓®ĒĢśĻ▓ī ņ”ØĻ░ĆĒĢśņŚ¼ ņĀäņ▓┤ ņĢäĒü¼ņÜ®ņĀæ(Arc Welding)ņØś ņĢĮ 30%ņØ┤ņāüņØä ņ░©ņ¦ĆĒĢśĻ│Ā ņ׳ļŗż3). FCWņØś ņé¼ņÜ®ļ╣äņ£©ņØĆ ņĪ░ņäĀĻ│╝ ņżæ┬ĘĒÖöĒĢÖĻ│ĄņŚģņŚÉņä£ Ļ░Ćņן ļåÆĻ│Ā, ņ×ÉļÅÖņ░©ļź╝ ņĀ£ņÖĖĒĢ£ ļ¬©ļōĀ ņśüņŚŁņŚÉņä£ 30%ņØ┤ņāüņØä ņ░©ņ¦ĆĒĢ£ļŗż3). Ēśäņ×¼ņŚÉļÅä FCWņØś ļåÆņØĆ ņāØņé░ņä▒Ļ│╝ ļ╣äņÜ®ņĀüņØĖ ĒÜ©Ļ│╝ļĪ£ ļŗżņ¢æĒĢ£ ņé░ņŚģļČäņĢ╝ļĪ£ ĒÖĢļīĆ ņĀüņÜ®ļÉśĻ│Ā ņ׳ļŗż.

ļ│Ė ļģ╝ļ¼ĖņØĆ ņĄ£ĻĘ╝ FCWņØś ņĀ£ņĪ░ĻĖ░ņłĀņĀü, ņ£ĀĒśĢļ│ä, Ļ░Ģņóģļ│ä Ļ░£ļ░£ ļÅÖĒ¢źņŚÉ ļīĆĒĢ┤ Ļ░üĻ░ü ņåīĻ░£ĒĢśĻ│Āņ×É ĒĢ£ļŗż.

2. Flux Cored WireņØś Ļ░£ņÜö

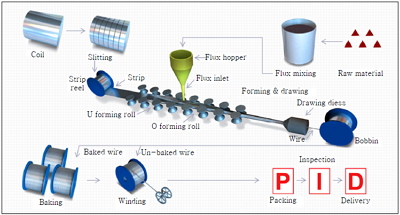

FCWļŖö ĻĖłņåŹ ņÖĖĒö╝ ļśÉļŖö ĒŖ£ļĖī(Metal Sheath or Tube)ņÖĆ ĒŖ£ļĖī ļé┤ļČĆņŚÉ ņČ®ņĀäļÉ£ Ēöīļ¤ŁņŖżļĪ£ ĻĄ¼ņä▒ļÉśņ¢┤ ņ׳ņ£╝ļ®░, ĻĖłņåŹ ĒŖ£ļĖīņØś ļŗ©ļ®┤ ļ¬©ņ¢æņØ┤ļéś Ēöīļ¤ŁņŖż ņĪ░ņä▒ņŚÉ ļö░ļØ╝ ļŗżņ¢æĒĢ£ ĒśĢĒā£ņØś FCWņØś ņĀ£ņĪ░Ļ░Ć Ļ░ĆļŖźĒĢśļŗż. Fig. 1Ļ│╝ 2ļŖö Ļ░üĻ░ü FCWņØś ņä▒ĒśĢ ĒöäļĪ£ņäĖņŖżņÖĆ ņĀ£ņĪ░ Ļ│ĄņĀĢņØä Ļ░£ļģÉņĀüņ£╝ļĪ£ ļ│┤ņŚ¼ņŻ╝ļŖö Ļ▓āņ£╝ļĪ£, ņŖżĒŖĖļ”ĮņØä Uņ×ÉĒśĢņ£╝ļĪ£ ņä▒ĒśĢĒĢśņŚ¼ ļé┤ļČĆņŚÉ ņé¼ņÜ®ļ¬®ņĀüņŚÉ ļö░ļØ╝ ņäżĻ│äļÉ£ Ēöīļ¤ŁņŖżļź╝ ļäŻņØĆ ļŗżņØī Oņ×ÉĒśĢņ£╝ļĪ£ ņä▒ĒśĢĒĢśĻ│Ā, ņä▒ĒśĢļÉ£ Oņ×ÉĒśĢ ĒŖ£ļĖīļź╝ ņøÉĒĢśļŖö ņ¦üĻ▓ĮĻ╣īņ¦Ć ņØĖļ░£ĒĢśņŚ¼ ņāØņé░ĒĢ£ļŗż. Oņ×ÉļĪ£ ņä▒ĒśĢ ņāØņé░ļÉ£ ņÖĆņØ┤ņ¢┤ņØś Ēæ£ļ®┤ņŚÉļŖö ņÖĆņØ┤ņ¢┤ ĻĖĖņØ┤ ļ░®Ē¢źņØä ļö░ļØ╝ ĒśĢņä▒ļÉ£ ņŗ¼(Seam)ļČĆĻ░Ć ļé©Ļ▓ī ļÉśļ®░, ņŗ¼ļČĆņØś ņĄ£ņóģ ļ¦łļ¼┤ļ”¼ ĒśĢĒā£ņŚÉ ļö░ļØ╝ ButtņÖĆ Overlap typeņ£╝ļĪ£ ĻĄ¼ļČäĒĢśĻĖ░ļÅä ĒĢ£ļŗż. ņØ╝ļ░śņĀüņ£╝ļĪ£ Overlap typeņØ┤ Butt typeņŚÉ ļ╣äĒĢ┤ ņŗ¼ļČĆņØś ļ▓īņ¢┤ņ¦ÉņØ┤ ņĀüņ¢┤ ĒØĪņŖĄņŚÉ ļīĆĒĢ£ ņśüĒ¢źņØ┤ ņĀüļŗż(Fig. 3). ņØ┤ņÖĆĻ░ÖņØ┤ Uņ×ÉņŚÉņä£ Oņ×ÉļĪ£ ņä▒ĒśĢ┬ĘņāØņé░ļÉśņ¢┤ ņŗ¼ļČĆļź╝ Ļ░Ćņ¦ĆĻ▓ī ļÉ£ ņÖĆņØ┤ņ¢┤ļź╝ Folded type ņÖĆņØ┤ņ¢┤ļØ╝ ĒĢśĻ│Ā, ņŗ¼ļČĆļź╝ ĒśĢņä▒ĒĢśņ¦Ć ņĢŖĻ▒░ļéś, ņÜ®ņĀæņŚÉ ņØśĒĢ┤ ņŗ¼ļČĆĻ░Ć ņĀ£Ļ▒░ļÉ£ Ļ▓āņØä Seamless(ņŗ¼ļ”¼ņŖż) type ņÖĆņØ┤ņ¢┤ļØ╝ ĒĢ£ļŗż(Fig. 4).

ļ¦łņ¦Ćļ¦ēņ£╝ļĪ£ ņØĖļ░£ņØ┤ ļüØļé£ Ēøä Ēæ£ļ®┤ņŚÉ ļé©ņĢäņ׳ļŖö ņ×öļźś ņ£żĒÖ£ņĀ£ļź╝ ņ▓śļ”¼ĒĢśĻ▓ī ļÉśļŖöļŹ░, 200-400┬░CņØś ņś©ļÅäņŚÉņä£ 1-10ņŗ£Ļ░ä Ļ▒┤ņĪ░ĒĢśņŚ¼ Ēæ£ļ®┤ņŚÉ ņé░ĒÖöĒö╝ļ¦ēņØä ĒśĢņä▒ņŗ£Ēé© Ļ▓āņØä ļ▓ĀņØ┤Ēü¼ļō£ ĒāĆņ×ģ(Baked type)ņØ┤ļØ╝ ĒĢśĻ│Ā, Ļ▒┤ņĪ░ Ļ│ĄņĀĢņØä ņāØļץĒĢśĻ│Ā ņÖĆņØ┤ņ¢┤ Ēæ£ļ®┤ņØś ņ×öļźś ņ£żĒÖ£ņĀ£ļź╝ ļ¼╝ļ”¼ņĀü, ĒÖöĒĢÖņĀüņ£╝ļĪ£ ņĀ£Ļ▒░ Ēøä ļ░®ņ▓Łņä▒Ļ│╝ ņåĪĻĖēņä▒ Ē¢źņāüņØä ļ¬®ņĀüņ£╝ļĪ£ ņĢĪņāü ļśÉļŖö Ļ│Āņ▓┤ņØś ņ▓śļ”¼ņĀ£ļź╝ ļÅäĒżĒĢ£ Ļ▓āņØä ņ¢Ėļ▓ĀņØ┤Ēü¼ļō£ ĒāĆņ×ģ(Unbaked type)ņØ┤ļØ╝ ĒĢ£ļŗż. ļśÉĒĢ£, Seamless FCWņÖĆ Ļ░ÖņØ┤ ĒŖ╣ņłśĒĢ£ Ļ▓ĮņÜ░ņŚÉļŖö ņÖĆņØ┤ņ¢┤ Ēæ£ļ®┤ņØä ĻĄ¼ļ”¼(Copper)ļÅäĻĖłĒĢśļŖö Ļ▓ĮņÜ░ļÅä ņ׳ļŗż.

FCAWļŖö GMAW(Gas Metal Arc Welding)ņÖĆ ņ£Āņé¼ĒĢśļéś ņżæņŗ¼ļČĆņŚÉ Ēöīļ¤ŁņŖż(Flux)Ļ░Ć ņ▒äņøīņĀĖ ņ׳ļŖö FCWļź╝ ņé¼ņÜ®ĒĢśņŚ¼ ņØ╝ņĀĢĒĢ£ ņåŹļÅäļĪ£ FCWļź╝ Ļ│ĄĻĖēĒĢśļ®┤ņä£ ņÜ®ņĀæļ╣äļō£Ļ░Ć ĒśĢņä▒ļÉśļÅäļĪØ ĒĢśļŖö ņÜ®ņĀæ ļ▓ĢņØ┤ļŗż4).

FCAWļŖö ļ│┤ĒśĖĻ░ĆņŖż ņé¼ņÜ® ņŚ¼ļČĆņŚÉ ļö░ļØ╝ Ļ░ĆņŖżļ│┤ĒśĖ(Gas Shielded) FCAWņÖĆ ņ×Éņ▓┤ļ│┤ĒśĖ(Self-Shielded) FCAWļĪ£ ĻĄ¼ļČäļÉśļ®░, ņÜ®ņ£ĄļČĆĻ░Ć ļ│┤ĒśĖĻ░ĆņŖż ļ░Å ņŖ¼ļלĻĘĖņŚÉ ņØśĒĢ┤ ņØ┤ņżæņ£╝ļĪ£ ļ│┤ĒśĖļÉśļŖö Ļ▓āņ£╝ļĪ£ņŹ©, GMAWņØś ņåöļ”¼ļō£ņÖĆņØ┤ņ¢┤(Solid Wire)ņÖĆļŖö ņé¼ņÜ®ĒĢśļŖö ĒśĢĒā£ļ¦ī ļŗżļź╝ ļ┐É ņøÉļ”¼ļŖö ļÅÖņØ╝ĒĢśļŗż. ĻĘĖļ¤¼ļéś ņ×Éņ▓┤ļ│┤ĒśĖ FCAWņŚÉņä£ļŖö ņÖĖļČĆņŚÉņä£ ņČöĻ░ĆņĀüņØĖ ļ│┤ĒśĖĻ░ĆņŖżĻ░Ć Ļ│ĄĻĖēļÉśņ¦Ć ņĢŖĻĖ░ ļĢīļ¼ĖņŚÉ SMAWņØś ņøÉļ”¼ņÖĆ ņ£Āņé¼ĒĢśĻ▓ī Ēöīļ¤ŁņŖżņŚÉņä£ ļ░£ņāØĒĢśļŖö ņ×Éņ▓┤ Ļ░ĆņŖżņÖĆ ņŖ¼ļלĻĘĖņŚÉ ņØśĒĢ┤ ņÜ®ņ£ĄļČĆĻ░Ć ļ│┤ĒśĖļÉ£ļŗż. ņ×Éņ▓┤ļ│┤ĒśĖ FCAWļŖö SMAW ļīĆļ╣ä ņÜ®ņ£ĄņåŹļÅä(Melting Rate)ņÖĆ ņÜ®ņ░®ņåŹļÅä(Deposition Rate)Ļ░Ć ļ¦żņÜ░ ļåÆņØĆ Ļ▓āņØ┤ ĒŖ╣ņ¦ĢņØ┤Ļ│Ā, ļ│┤ĒśĖĻ░ĆņŖżļź╝ ņé¼ņÜ®ĒĢśņ¦Ć ņĢŖņ£╝ļ»ĆļĪ£ ņśźņÖĖņØś ļ░öļ×īņØ┤ ļČĆļŖö Ļ││ņŚÉņä£ļÅä ņÜ®ņĀæņ×æņŚģņØ┤ Ļ░ĆļŖźĒĢśļŗż. ļśÉĒĢ£, ņÜ®ņĀæĒåĀņ╣śĻ░Ć Ļ░Ćļ│ŹĻ│Ā ņĪ░ņ×æĒĢśĻĖ░ ņē¼ņøī ņ×æņŚģņ×ÉņØś Ēö╝ļĪ£ļÅäĻ░Ć ņĀüņ£╝ļ»ĆļĪ£ ņ×æņŚģ ļŖźļźĀņØä Ē¢źņāüņŗ£Ēé¼ ņłś ņ׳ļŗż4).

FCWņŚÉņä£ Ēöīļ¤ŁņŖżļŖö ņÜ®ņ░®ĻĖłņåŹņØś ĻĖ░Ļ│äņĀü ļ¼╝ņä▒ņ╣śņÖĆ ņÜ®ņĀæ ņ×æņŚģņä▒ņØä ņĪ░ņĀĢĒĢśļ®░, ņĢäĒü¼(Arc) ņĢłņĀĢņĀ£, ņŖ¼ļלĻĘĖ ĒśĢņä▒ņĀ£, Ēāłņé░ņĀ£, Ēāłņ¦łņĀ£, Ļ░ĆņŖż ĒśĢņä▒ņĀ£, ĻĘĖļ”¼Ļ│Ā ĒĢ®ĻĖłņä▒ļČä ļō▒ņØä ĒżĒĢ©ĒĢ£ļŗż5) ļīĆĒæ£ņĀüņ£╝ļĪ£ ļŻ©ĒāĆņØ╝(Rutile)ņØä ņŻ╝ņä▒ļČäĻ│äļĪ£ ĒĢśļŖö ņé░ņä▒Ļ│ä ņŖ¼ļלĻĘĖ ņĪ░ņä▒ņØä Ļ░Ćņ¦ł Ļ▓ĮņÜ░ ņ×æņŚģņä▒ņØ┤ ļ¦żņÜ░ ņÜ░ņłśĒĢśĻ│Ā ņĀäņ×ÉņäĖ ņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢśļŗż. ļśÉĒĢ£, ļ╣äļō£ ņÖĖĻ┤ĆņØ┤ļéś ņŖ¼ļלĻĘĖ ļ░Ģļ”¼ņä▒ņØä ņóŗĻ▓ī ĒĢśĻĖ░ ņ£äĒĢ┤ņä£ ņåīļ¤ēņØś ĒŖ╣ņĀĢ ĒÖöĒĢ®ļ¼╝ņØ┤ ņ▓©Ļ░Ć ļÉśĻ│Ā ņ׳ņ£╝ļ®░, ņŖ¼ļלĻĘĖņØś ļ¼╝ļ”¼ņĀü ņä▒ņ¦łņØä ņĪ░ņĀĢĒĢśņŚ¼ ņłśņ¦ü ņāüņ¦ä ļ░Å ĒĢśņ¦ä ņÜ®ņĀæņä▒ņØ┤ ņÜ░ņłśĒĢśļÅäļĪØ ņĀ£ņĪ░ļÉ£ ņĀ£ĒÆłļÅä ņ׳ļŗż. CaOņÖĆ CaF2ļź╝ ņŻ╝ņä▒ļČäĻ│äļĪ£ ĒĢśļŖö ņŚ╝ĻĖ░ņä▒Ļ│ä ņŖ¼ļלĻĘĖ ņĪ░ņä▒ņØä Ļ░Ćņ¦ł Ļ▓ĮņÜ░ ņÜ®ņĀæļČĆ ņØĖņä▒ņØ┤ ņÜ░ņłśĒĢśļéś, ņ×æņŚģņä▒ņØ┤ ņŚ┤ņĢģĒĢśĻ│Ā ņĀäņ×ÉņäĖ ņÜ®ņĀæņØ┤ ņ¢┤ļĀżņøīņ¦äļŗż. ļ¦łņ¦Ćļ¦ēņ£╝ļĪ£ ĻĖłņåŹ ļČäļ¦ÉņØ┤ ņŻ╝ņä▒ļČäņØĖ Ēöīļ¤ŁņŖżļź╝ ņé¼ņÜ®ĒĢĀ Ļ▓ĮņÜ░ņŚÉļŖö ļ®öĒāł ņĮöņ¢┤ļō£ ņÖĆņØ┤ņ¢┤(Metal Cored Wire, ņØ┤ĒĢś MCW)ļØ╝ ĒĢśļ®░, ņŖ¼ļלĻĘĖĻ░Ć ņāØņä▒ļÉśņ¦Ć ņĢŖņĢä ļ│┤ĒśĖĻ░ĆņŖżļź╝ ņé¼ņÜ®ĒĢśņŚ¼ņĢ╝ļ¦ī ĒĢ£ļŗż6). ļ│┤ĒśĖĻ░ĆņŖżļĪ£ļŖö Ar ļśÉļŖö Ar+CO2ņØś Ēś╝ĒĢ®Ļ░ĆņŖżļź╝ ņé¼ņÜ®ĒĢśļŖö Ļ▓āņØ┤ ņØ╝ļ░śņĀüņØ┤Ļ│Ā, ņåöļ”¼ļō£ņÖĆņØ┤ņ¢┤ ļ│┤ļŗż ļŗ©ņ£äļ®┤ņĀüļŗ╣ ņĀäļźśļ░ĆļÅäļź╝ ļåÆņØ╝ ņłś ņ׳ņ¢┤ ņĢĮ 20~30%ņĀĢļÅä ļåÆņØĆ ņÜ®ņ░®ņåŹļÅäļĪ£ ņāØņé░ņä▒ņØä Ē¢źņāüņŗ£Ēé¼ ņłś ņ׳ļŗż4).

3. Flux Cored Wire ņĀ£ņĪ░ ĻĖ░ņłĀ

3.1 Seamless Flux Cored Wire

ņÜ®ņĀæņ×¼ļŻīņŗ£ņןņØĆ ĻĖ░ņĪ┤ Ļ│ĀĻ░ĆņØś Seamless FCWļź╝ ņĀĆļĀ┤ĒĢ£ Ļ░ĆĻ▓®ņ£╝ļĪ£ ļīĆļ¤ē ņāØņé░ņØ┤ Ļ░ĆļŖźĒĢ£ Seamless FCW ņĀ£ņĪ░ ĻĖ░ņłĀ Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż.

Seamless FCWļŖö ĻĖ░ņĪ┤ Folded typeņØ┤ Ļ░Ćņ¦ĆĻ│Ā ņ׳ļŖö ņŗ¼ļČĆļź╝ ņĀ£Ļ▒░ĒĢ©ņ£╝ļĪ£ņŹ©, Fig. 5ņÖĆ Ļ░ÖņØ┤ ļŗżņŖĄĒĢ£ ĒÖśĻ▓ĮņŚÉņä£ļÅä ņןņŗ£Ļ░ä ļé┤ļČĆ Ēöīļ¤ŁņŖżņØś ņłśļČä ĒØĪņŖĄņØ┤ ņŚåņ¢┤ ņÜ®ņ░®ĻĖłņåŹņØś ņłśņåīĒĢ©ņ£Āļ¤ēņØä ļé«ņČöņ¢┤ ņĀĆņś©ĻĘĀņŚ┤ ļ░£ņāØņØä ņżäņØ╝ ņłś ņ׳Ļ│Ā, ļŹöļČłņ¢┤ ņÜ®ņĀæļČĆņØś ņø£ĒÖĆ(Wormhole) ļ░£ņāØļÅä Ļ░Éņåīņŗ£Ēé¼ ņłś ņ׳ļŗż. ļśÉĒĢ£, ĻĖ░ņĪ┤ Folded typeņØś Ļ▓ĮņÜ░ ņÜ®ņĀæ Ēøä ĒØĪņŖĄņØś ņÜ░ļĀżļĪ£ ņØ╝ņĀĢĻĖ░Ļ░ä ņé¼ņÜ® Ēøä ļé©ņØĆ ņÖĆņØ┤ņ¢┤ņØä ĒÅÉĻĖ░ĒĢśņśĆļŗż. ņØ┤ļź╝ ņĄ£ņåīĒÖö ņŗ£ĒéżĻĖ░ ņ£äĒĢ┤ ņåīļ¤ēņØś Folded type ņŖżĒÆĆ ĒśĢĒā£ļĪ£ ņé¼ņÜ®ĒĢśļŖö Ļ▓ĮņÜ░ļÅä ņ׳ņ¦Ćļ¦ī, Seamless FCWņØś Ļ▓ĮņÜ░ ņ×öļ¤ēņØ┤ ļé©ļŹöļØ╝ļÅä ĒØĪņŖĄņØ┤ ļ░£ņāØĒĢśņ¦Ć ņĢŖņĢä ļō£ļ¤╝ņØś ļīĆņÜ®ļ¤ē ĒśĢĒā£ļĪ£ ņé¼ņÜ®ņØ┤ Ļ░ĆļŖźĒĢśĻ│Ā ņé¼ņÜ®ņ×ÉņØś ņ×ģņןņŚÉņä£ļŖö ņÖĆņØ┤ņ¢┤ņØś ļ│┤Ļ┤ĆĻ│╝ Ļ┤Ćļ”¼Ļ░Ć ņē¼ņøīņ¦ĆĻ▓ī ļÉ£ļŗż.

Fig.┬Ā5

Diffusible hydrogen variation of folded and Seam- less type Flux Cored Wire with exposure time

ļ¼╝ļ”¼ņĀü ĒŖ╣ņä▒ņ£╝ļĪ£ļŖö ņŗ¼ļČĆĻ░Ć ņŚåņ£╝ļ»ĆļĪ£, ņÖĆņØ┤ņ¢┤ ņ×Éņ▓┤ņØś Ēæ£ļ®┤ ņØ┤ļ░®ņä▒ņØ┤ Ļ░£ņäĀļÉśņ¢┤ ņÜ®ņĀæ ņ╝ĆņØ┤ļĖöņŚÉņä£ ĒåĀņ╣śļĪ£ Ļ│ĄĻĖēļÉ£ ņÖĆņØ┤ņ¢┤Ļ░Ć ņ╗©ĒģŹĒŖĖ Ēīü(Contact Tip)ņ£╝ļĪ£ ņØ╝ņĀĢĒĢśĻ▓ī ļÅīņČ£ļÉśļŖö ņÖĆņØ┤ņ¢┤ņØś ĒāĆĻ▓¤(Target) ĒŖ╣ņä▒Ļ│╝ ņåĪĻĖē ņä▒ļŖźņØ┤ Ļ░£ņäĀļÉśĻ│Ā, ĻĄĮĒלĻ│╝ ļ╣äĒŗĆļ”╝ņŚÉ ļö░ļźĖ Ēöīļ¤ŁņŖżņØś ņ£ĀņČ£ņØ┤ ņŚåņ£╝ļ®░, Ēæ£ļ®┤ņ£╝ļĪ£ ĒØÉļź┤ļŖö ņĀäļźśĻ░Ć ĻĘĀņØ╝ĒĢśņŚ¼ ņĢäĒü¼Ļ░Ć ņĢłņĀĢĒÖö ļÉśļ»ĆļĪ£ ļĪ£ļ┤ćņÜ®ņĀæĻ│╝ Ļ░ÖņØĆ ņ×ÉļÅÖņÜ®ņĀæ ņŗ£ ņŖżĒī©Ēä░(Spatter) ļ░£ņāØĻ│╝ ņĢäĒü¼ ļČłņĢłņĀĢņŚÉ ļö░ļźĖ ĒÆłņ¦ł ļČłļ¤ēņØä Ļ░£ņäĀ ĒĢĀ ņłś ņ׳ļŗż.

ĻĘĖļ¤¼ļéś ņØ┤ļ¤¼ĒĢ£ ļŗżņ¢æĒĢ£ ņןņĀÉņŚÉļÅä ļČłĻĄ¼ĒĢśĻ│Ā Seamless type FCWļŖö Folded type FCWņŚÉ ļ╣äĒĢ┤ ņØ╝ļ░śĒÖö ļÉśņ¦Ć ļ¬╗ĒĢśņśĆļŖöļŹ░, ĻĘĖ ņØ┤ņ£ĀļŖö ņāØņé░ļ░®ņŗØņØ┤ ņŚ░ņåŹņĀüņØ┤ņ¦Ć ļ¬╗ĒĢśĻ│Ā, Pipe ļé┤ļČĆņŚÉ Ēöīļ¤¼ņŖżļź╝ ņČ®ņĀä Ēøä ņØ┤ļź╝ ļŗżņŗ£ Ļ▒┤ņĪ░ņÖĆ ņØĖļ░£, ĻĄ¼ļ”¼ ļÅäĻĖłĒĢśņŚ¼ ĻČīņĘ©ĒĢśļŖö ĒśĢĒā£7)ļĪ£ ņÖĆņØ┤ņ¢┤ ņ×Éņ▓┤ ņāØņé░ļ╣äņÜ®ņĀüņØĖ ņĖĪļ®┤ņŚÉņä£ ņāüļŗ╣Ē׳ ļČłļ”¼ĒĢ©ņØä Ļ░Ćņ¦ĆĻ│Ā ņ׳ņŚłļŗż(Fig. 6). ņØ┤ļź╝ ĻĘ╣ļ│ĄĒĢśĻĖ░ ņ£äĒĢ┤ Folded typeņ£╝ļĪ£ ņĀ£ņĪ░ĒĢśļŖö Ļ│╝ņĀĢņŚÉņä£ ņĀäĻĖ░ ņĀĆĒĢŁ ņÜ®ņĀæ(Electric Resistance Welding, ERW)ņØ┤ļéś8), ĒöīļØ╝ņ”łļ¦ł(Plasma), GTAW(Gas Tungsten Arc Welding)ļź╝ ņé¼ņÜ®ĒĢśņŚ¼ ņŗ¼ļČĆ ņ×Éņ▓┤ļź╝ ņÜ®ņĀæĒĢśļŖö ĒöäļĪ£ņäĖņŖżĻ░Ć ļÅäņ×ģļÉśņŚłņ£╝ļéś(Fig. 7), ņÜ®ņĀæ ņŗ£ ļé┤ļČĆ Ēöīļ¤ŁņŖżĻ░Ć ņŗ¼ļČĆ ņÜ®ņĀæņŚÉ ņØśĒĢ┤ ļ░£ņāØĒĢśļŖö ņŚ┤ņØ┤ļéś ņĢäĒü¼ņŚÉ ļģĖņČ£ļÉśņ¢┤ ĒŖ╣ņä▒ņØ┤ ļ│ĆĒĢśĻ▒░ļéś ĒĢ©Ļ╗ś ņÜ®ņ£ĄļÉśļŖö ļ¼ĖņĀ£ļĪ£ ņāØņé░ņä▒ņØä ļåÆņØ┤ļŖö Ļ▓āņŚÉļŖö ĒĢ£Ļ│äļź╝ Ļ░Ćņ¦ĆĻ│Ā ņ׳ņŚłļŗż. ņĄ£ĻĘ╝ ņØ┤ļ¤¼ĒĢ£ ĒĢ£Ļ│äļź╝ ĻĘ╣ļ│ĄĒĢ£ Seamless Ļ│ĄņĀĢņØ┤ ĻĄŁļé┤ņŚÉņä£ Ļ░£ļ░£ļÉśņ¢┤ ĒŖ╣ĒŚł ļō▒ļĪØņØ┤ ņÖäļŻī ļÉśņ¢┤ ņ׳ļŗż9). ņØ┤ ļ░®ļ▓ĢņØĆ ņä▒ĒśĢļÉ£ FCWļź╝ ļŗżņŗ£ ĒĢ£ļ▓ł FoldedĒĢśņŚ¼ ņØ┤ņżæĻ┤Ć ĒśĢĒā£ļĪ£ ņĀ£ņ×æĒĢ£ Ēøä ņØ┤ņżæ FoldedņŚÉ ņØśĒĢ┤ ĒśĢņä▒ļÉ£ ņŗ¼ļČĆļź╝ ņÜ®ņĀæĒĢ©ņ£╝ļĪ£ņŹ© ņĢäĒü¼Ļ░Ć ņ¦üņĀæ ļé┤ļČĆ Ēöīļ¤ŁņŖżņŚÉ ņśüĒ¢źņØä ļ»Ėņ╣śņ¦Ć ņĢŖĻ▓ī ĒĢśņŚ¼ ĻĖ░ņĪ┤ņØś ļ¼ĖņĀ£ņĀÉņØä Ļ░£ņäĀĒĢ©ņ£╝ļĪ£ņŹ© ņāØņé░ņä▒ņØä ĒÖĢļ│┤ ĒĢĀ ņłś ņ׳Ļ▓ī ĒĢ£ Ļ▓āņØ┤ļŗż(Fig. 8). ļśÉĒĢ£ ĻĖ░ņĪ┤ņØś SeamlessļŖö Ēæ£ļ®┤ņŚÉ ĻĄ¼ļ”¼ļź╝ ļÅäĻĖłĒĢśņŚ¼ ņĀäĻĖ░ņĀäļÅäļÅäņÖĆ ļ░®ņ▓Łņä▒ņØä ĒÖĢļ│┤ĒĢśĻ│Ā, ļé«ņØĆ ņ╗©ĒģŹĒŖĖ Ēīü ļ¦łļ¬©ļÅäļź╝ Ļ░£ņäĀ ĒĢśņśĆņ£╝ļéś, ņāüĻĖ░ ļ░®ņŗØņ£╝ļĪ£ ņāØņé░ļÉ£ ņÖĆņØ┤ņ¢┤ļŖö ĻĖ░ņĪ┤ Folded typeņŚÉņä£ ņāØņé░ĒĢśļŖö ļ░®ņŗØĻ│╝ ļÅÖņØ╝ĒĢśĻ▓ī Ēæ£ļ®┤ļÅäĻĖł ņŚåņØ┤ Ļ▒┤ņĪ░ĒāĆņ×ģ(Baked Type)ņØ┤ļéś ļ╣äĻ▒┤ņĪ░ĒāĆņ×ģ(Unbaked type)ņ£╝ļĪ£ ņāØņé░ņØ┤ Ļ░ĆļŖźĒĢśĻ│Ā ļ░®ņ▓Łņä▒Ļ│╝ ņ╗©ĒģŹĒŖĖ Ēīü ļ¦łļ¬©ļÅäļÅä ņÜ░ņłśĒĢśļŗż(Fig. 9, 10).

3.2 Flux Core Wire Ēæ£ļ®┤ ņ▓śļ”¼ ĻĖ░ņłĀ

FCWļŖö ņןņŗ£Ļ░ä Ļ│ĀņåŹ ņÜ®ņĀæņŚÉ ņé¼ņÜ®ļÉśļ»ĆļĪ£, ņåĪĻĖēņØ┤ ņøÉĒÖ£ ĒĢśņ¦Ć ļ¬╗ĒĢĀ Ļ▓ĮņÜ░ ļ╣łļ▓łĒĢ£ ņ×æņŚģņżæļŗ©ņØä Ļ░ĆņĀĖņÖĆ ņāØņé░ņä▒ņØä ņĀĆĒĢśņŗ£Ēé©ļŗż. ļśÉĒĢ£, ņÜ®ņĀæņ×¼ļŻī ņĀ£ņĪ░ņé¼ļōżņØĆ ņןņŗ£Ļ░ä ļ│┤Ļ┤Ć ņŗ£ņŚÉļÅä ņÖĆņØ┤ņ¢┤ Ēæ£ļ®┤ņŚÉ ļģ╣ņØ┤ ļ░£ņāØĒĢśņ¦Ć ņĢŖļŖö ĻĖ░ņłĀ Ļ░£ļ░£ņØä ļŗżņ¢æĒĢ£ ļ░®ļ▓Ģņ£╝ļĪ£ ņ¦äĒ¢ēĒĢśĻ│Ā ņ׳ļŗż.

ņāØņé░Ļ│ĄņĀĢņØś ņä▒ĒśĢ ļ░Å ņØĖļ░£ ņŗ£ ņé¼ņÜ®ļÉśļŖö ņ£żĒÖ£ņĀ£ņÖĆ ņÖĆņØ┤ņ¢┤ņØś ņåĪĻĖēņä▒, ļ░®ņ▓Łņä▒, Ēæ£ļ®┤ņĀäĻĖ░ņĀäļÅä Ē¢źņāüņØä ņ£äĒĢ£ ņÖĆņØ┤ņ¢┤ Ēæ£ļ®┤ ņ▓śļ”¼ņĀ£ ļō▒ņŚÉ ļīĆĒĢ┤ ņ¦ĆņåŹņĀüņØĖ ņŚ░ĻĄ¼ļź╝ ņ¦äĒ¢ēĒĢśĻ│Ā ņ׳ļŗż. ņØ┤ļ¤░ Ēæ£ļ®┤ ņ▓śļ”¼ ĻĖ░ņłĀņØĆ Ļ░ü ņĀ£ņĪ░ņé¼ņØś ļ╣äĻ│ĄņŗØņĀüņØĖ ļģĖĒĢśņÜ░ļĪ£ ņÖĖļČĆņŚÉļŖö ņĢīļĀżņĀĖ ņ׳ņ¦Ć ņĢŖņ¦Ćļ¦ī Ļ▓Įņ¤üņĀüņ£╝ļĪ£ ĻĖ░ņłĀ Ļ░£ļ░£ņØä ņ¦äĒ¢ē ņżæņØ┤ļŗż.

4. Flux Cored Wire Type ļ│ä Ļ░£ļ░£ ļÅÖĒ¢ź

4.1 RutileĻ│ä Flux Cored Wire

4.1.1 ĒøäņŚ┤ņ▓śļ”¼(Post Weld Heat Treatment, PWHT)ņÜ®

ņØ╝ļ░śņĀüņØĖ RutileĻ│ä Flux Cored WireļŖö ĒøäņŚ┤ņ▓śļ”¼ Ēøä ņČ®Ļ▓®ņØĖņä▒ņØ┤ ĻĖēĻ▓®Ē׳ Ļ░ÉņåīĒĢśļŖö ĒŖ╣ņ¦Ģņ£╝ļĪ£ ņé¼ņÜ®ņØ┤ ņĀ£ĒĢ£ņĀü ņØ┤ņśĆņ£╝ļéś, 2000ļģäļīĆ ņ┤łļ░ś AWS A5.20 E71T-9XĻ│äņŚ┤ņØś ĒøäņŚ┤ņ▓śļ”¼ ņĀäņÜ® FCWĻ░Ć Ļ░£ļ░£ļÉśņ¢┤ ņĀüņÜ®ļÉśĻĖ░ ņŗ£ņ×æĒĢśņśĆĻ│Ā, Ēśäņ×¼ļŖö ĻĄŁļé┤ņŚÉņä£ļÅä ļ▓öņÜ®ņĀüņ£╝ļĪ£ ņāØņé░ ĒīÉļ¦żĒĢśĻ│Ā ņ׳ļŗż. ņĄ£ĻĘ╝ņŚÉļŖö ĒøäņŚ┤ņ▓śļ”¼ņÜ® AWS A5.29 E81T-K2XņÖĆ E91T-K2XĻ│äņŚ┤ņØś FCWĻ░Ć Ļ░£ļ░£ļÉśņ¢┤ ĒøäņŚ┤ņ▓śļ”¼ ĒøäņŚÉļÅä -60┬░CĻ╣īņ¦Ć ņČ®Ļ▓®ņØĖņä▒ņØä ļ│┤ņ”ØĒĢśĻ│Ā ņ׳ļŗż. Drilling PipeņÜ®ņ£╝ļĪ£ ņé¼ņÜ®ļÉśļŖö ASTM A519 Gr. 4130 ņÜ®ņ£╝ļĪ£ļŖö ņØĖņןĻ░ĢļÅä 720MpaņØ┤ņāü, NACE(National Association of Corrosion Engineers)ņØś ņÜöĻĄ¼ņé¼ĒĢŁņØĖ Max. 1.0%NiņØä ļ¦īņĪ▒ĒĢśļ®┤ņä£ -40┬░C ņČ®Ļ▓®ņØĖņä▒ņØä ļ│┤ņ”ØĒĢ┤ņĢ╝ ĒĢśļŖö Ļ╣īļŗżļĪ£ņÜ┤ ĻĘ£Ļ▓®ņØä ļ¦īņĪ▒ĒĢśļŖö ĒøäņŚ┤ņ▓śļ”¼ņÜ® FCWĻ░Ć ĻĄŁļé┤ņŚÉņä£ Ļ░£ļ░£ļÉśņ¢┤ ĻĄŁļé┤ņÖĖ ņĪ░ņäĀņåīņŚÉ ņĀüņÜ® ņżæņØ┤ļŗż.

4.1.2 Ļ│ĀņåŹ Fillet ņÜ®ņĀæņÜ®

ļ│┤ņłśņÜ®ņĀæņØ┤ ņĀüĻ│Ā, Ļ│ĀņåŹņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢ£ ĒĢäļ”┐(Fillet)ņĀäņÜ® ņÜ®ņĀæņ×¼ļŻīĻ░Ć Ļ░£ļ░£ļÉśņ¢┤ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ņ£╝ļ®░11), ņóģļלņŚÉļŖö ņŗ▒ĻĖĆ ņśżĒåĀņ╝Ćļ”¼ņ¦Ć(Single Auto-Carriage) ĻĖ░ņżĆ 50~80 cpm cm/min)ņØś ņåŹļÅäņŚÉņä£ ņé¼ņÜ®ļÉśņ¢┤ ņÖöņ£╝ļéś, ņĄ£ĻĘ╝ 100~ 20 cpmņØś ņ┤łĻ│ĀņåŹņŚÉņä£ļÅä ļé┤ĻĖ░Ļ│Ąņä▒Ļ│╝ ņ¢æĒśĖĒĢ£ ļō▒Ļ░üņןņØä ĒśĢņä▒ĒĢśļŖö ņÜ®ņĀæņ×¼ļŻīņØś Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż. ĒŖ╣Ē׳ ņäĀļ░ĢņØś Ļ▒┤ņĪ░ Ļ│ĄņĀĢņŚÉņä£ ņĀäņ▓┤ ņÜ®ņĀæļČĆņØś 70%ņĀĢļÅäļź╝ ņ░©ņ¦ĆĒĢśļŖö ĒöäļØ╝ņØ┤ļ©Ė(Primer) ļÅäĒż Ļ░ĢĒīÉņØś ĒĢäļĀø ņÜ®ņĀæļČĆņŚÉ ļīĆĒĢ£ Ļ│ĀņåŹĒÖö, Ļ│ĀĒÜ©ņ£©ĒÖö, Ļ│ĀĒÆłņ¦łĒÖöļź╝ ņÜöĻĄ¼ĒĢśĻ│Ā ņ׳ļŗż.

20ņŚ¼ļģä ņĀäņŚÉļŖö ļŗ©ņØ╝ņĀäĻĘ╣ņØś Flux Cored Wire ņÜ®ņĀæņ×¼ļŻīļź╝ ņØ┤ņÜ®ĒĢ┤ 80 cpm ņĀĢļÅäņŚÉ ļ©Ėļ¼╝ļĀĆļŹś ņÜ®ņĀæņåŹļÅäĻ░Ć TOP (Twin- Tandem One Pool)12) ņÜ®ņĀæļ▓ĢņØś ņĀüņÜ®ņØä ĒåĄĒĢ┤ 150 cpm ņĀĢļÅäļĪ£ ņĢĮ 2ļ░░ ņ”ØĻ░Ć ĒĢśņśĆņ£╝ļ®░, ņĄ£ĻĘ╝ņŚÉļŖö ņÜ®ņĀæņåŹļÅäļź╝ 200 cpm ņØ┤ņāü Ļ│ĀņåŹņ£╝ļĪ£ ņłśĒÅē ĒĢäļ”┐ ņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢśļÅäļĪØ ņÜ®Ļ░ĆņÖĆņØ┤ņ¢┤(Filler Wire)ļź╝ ņäĀ, ĒøäĒ¢ē ņĀäĻĘ╣ ņé¼ņØ┤ņŚÉ ņéĮņ×ģņŗ£ņ╝£ Ļ│ĀņÜ®ņ░® ļ░Å ņÜ®ņ£Ąņ¦Ć ņĢłņĀĢĒÖöļź╝ ļÅäļ¬©ĒĢ£ ņāłļĪ£ņÜ┤ ņŗ£Ļ│Ąļ▓ĢĻ│╝ ļé┤ĻĖ░Ļ│Ąņä▒ņØ┤ ĒāüņøöĒĢ£ Metal Flux Cored WireņØś ņŚ░ĻĄ¼ļÅä ļ│┤Ļ│ĀļÉśĻ│Ā ņ׳ļŗż13,14).

4.2 Metal Cored Wire

ņ×ÉļÅÖņ░©ņØś ļīĆĒæ£ņĀüņØĖ Ēæ£ļ®┤ņ▓śļ”¼Ļ░ĢĒīÉņØĆ GI(Galvanized), GA(Galvannealed), EG(Electro-galvanized)ņØś ņĢäņŚ░ļÅäĻĖłĻ░ĢĒīÉņ£╝ļĪ£ ļĪ£ļ┤ć ņÜ®ņĀæĻ│ĄņĀĢņØä ĒåĄĒĢśņŚ¼ ņÜ®ņĀæņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ņ£╝ļ®░15). ĻĖ░ņĪ┤ AWS A5.18 ER70S-X Ļ│äņŚ┤ņØś ņåöļ”¼ļō£ņÖĆņØ┤ņ¢┤ļź╝ ļīĆļČĆļČä ņé¼ņÜ® ņżæņØ┤ļŗż. ĻĘĖļ¤¼ļéś ņĢäņŚ░ļÅäĻĖłĻ░ĢĒīÉņŚÉ ņÜ®ņĀæ ņŗ£ Si islandĻ░Ć ļ░£ņāØĒĢśņŚ¼ ņÜ®ņĀæ Ēøä ļÅäņןņØä ņ£äĒĢ┤ Si islandļź╝ ņĀ£Ļ▒░ĒĢśļŖö ļČłĒĢäņÜöĒĢ£ ĒøäņåŹĻ│ĄņĀĢņØ┤ ĒĢäņÜöĒĢśĻ▓ī ļÉ£ļŗż. ņØ┤ļź╝ ļ│┤ņÖäĒĢśĻĖ░ ņ£äĒĢ┤ ĻĖ░ņĪ┤ Soild wireļīĆļ╣ä Si island ļ░£ņāØņØä ņĀĆĻ░Éņŗ£Ēé¼ ņłś ņ׳ļŖö Metal Cored WireĻ░Ć Ļ░£ļ░£ļÉśĻ│Ā ņ׳ņ£╝ļ®░, CO2, Ar +CO2 Ēś╝ĒĢ®Ļ░ĆņŖżņŚÉņä£ ņåöļ”¼ļō£ņÖĆņØ┤ņ¢┤ ļīĆļ╣ä ņĀüņØĆ ņŖżĒī©Ēä░ ļ░£ņāØĻ│╝ Ļ│ĀņÜ®ņ░® ņåŹļÅäļź╝ Ļ░Ćņ¦Ćļ»ĆļĪ£ ņāØņé░ņä▒ņØä Ē¢źņāüņŗ£Ēé¼ ņłś ņ׳ļŗż.

ņĪ░ņäĀ ļ░Å ņżæĻ│ĄņŚģļČäņĢ╝ņŚÉ ņ׳ņ¢┤ņä£ļŖö ņ×ĀņłśĒĢ©Ļ│╝ Ļ░ÖņØ┤ ĻĄ░ņé¼ņÜ® ļ¬®ņĀüņ£╝ļĪ£ Ļ│ĀņןļĀź, Ļ│ĀņØĖņä▒ņØä ņÜöĻĄ¼ĒĢśļŖö 760Mpa ņØ┤ņāüņØś ņØĖņןĻ░ĢļÅäļź╝ Ļ░Ćņ¦ĆļŖö Ļ│ĀĻ░ĢļÅä Ļ│ĀņØĖņä▒ MCWļź╝ Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēņżæņŚÉ ņ׳ļŗż.

ļśÉĒĢ£, ļīĆĻĄ¼Ļ▓Į ņÖĆņØ┤ņ¢┤ņØś MCWļĪ£ SAW(Submerged Are Welding) ņÖĆņØ┤ņ¢┤ļź╝ ļīĆņ▓┤ ĒĢĀ ņłś ņ׳ņ£╝ļ®░, ņåöļ”¼ļō£ ĒśĢĒā£ņØś SAWņÖĆņØ┤ņ¢┤ņÖĆ ļŗ¼ļ”¼ Ļ╣īļŗżļĪ£ņÜ┤ Ļ│Ąņé¼ ņÜöĻĄ¼ ņĪ░Ļ▒┤ņØä ļ¦īņĪ▒ņŗ£ĒéżĻĖ░ ņ£äĒĢ£ ņä▒ļČäĻ│ä ņĪ░ņĀłņØ┤ ļ╣äĻĄÉņĀü ņÜ®ņØ┤ĒĢśļŗż. Ēśäņ×¼ļŖö ĒĢśļō£ĒÄśņØ┤ņŗ▒(Hardfcaing) ļČäņĢ╝ņØś wear plate ņĀ£ņĪ░ņŚÉ ņé¼ņÜ®ļÉśļŖö Open Arc typeĻ│╝ SAW Composite WireļĪ£ ļīĆĻĄ¼Ļ▓Į MCWĻ░Ć ņĀ£ĒĢ£ņĀüņ£╝ļĪ£ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ņ¦Ćļ¦ī, HRC 65 ņØ┤ņāüņØś Ļ▓ĮļÅäļź╝ ņÜöĻĄ¼ĒĢśĻ▒░ļéś, ņŚ░ņŻ╝ļĪż ļ│┤ņłśņÜ®ņĀæņŚÉ ņ׳ņ¢┤ ļé┤ĻĄ¼ņä▒ņØ┤ ņÜ░ņłśĒĢ£ ņä▒ļČäĻ│äņØś Ļ░£ļ░£ņŚÉ ņ┤łņĀÉņØ┤ ļ¦×ņČöņ¢┤ņĀĖ ņ׳ļŗż.

4.3 Self-Shielded Flux Cored Wire

ņ×Éņ▓┤ļ│┤ĒśĖ FCWļŖö ļ│┤ĒśĖĻ░ĆņŖżļź╝ ņé¼ņÜ®ĒĢśņ¦Ć ņĢŖņ£╝ļ»ĆļĪ£, ņØ┤ļÅÖņØ┤ ĒÄĖļ”¼ĒĢśĻ│Ā ļ│┤ĒśĖĻ░ĆņŖż ļģĖņ”ÉņØ┤ ĒĢäņÜöĒĢśņ¦Ć ņĢŖņĢä T, K, Y JointņÖĆ Ļ░ÖņØĆ Pipe ņÜ®ņĀæņØ┤ļéś, ĒśæĻ░£ņäĀ(Narrow Gap) ļČĆņ£äņØś ņ┤łņĖĄņÜ®ņĀæņÜ®ņ£╝ļĪ£ ņĀüĒĢ®ĒĢśļŗż(Fig. 12).

ĻĘĖļ¤¼ļéś ņÜ®ņĀæņĪ░Ļ▒┤ņØś ļ▓öņ£äĻ░Ć ņóüĻ│Ā, ĒØĪņŖĄņŚÉ ļīĆĒĢ£ ņĀĆĒĢŁņä▒ņØ┤ ļé«ņĢä ļ│┤Ļ┤ĆņāüņØś ņ¢┤ļĀżņøĆņØ┤ ņ׳ņ¢┤ ĒĢ£ņĀĢļÉ£ ļČĆņ£äņŚÉ ņĀüņÜ®ļÉśĻ│Ā ņ׳ņ¦Ćļ¦ī, ņØ┤ļ¤░ ĒĢ£Ļ│äļź╝ ĻĘ╣ļ│ĄĒĢśĻĖ░ ņ£äĒĢ£ ļģĖļĀźņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳Ļ│Ā, Ē¢źĒøä RutileĻ│ä FCWņÖĆ SMAWņØś Covered Electrodeļź╝ ļīĆņ▓┤ĒĢ┤ ļéśĻ░ł ņÜ®ņĀæņ×¼ļŻīļĪ£ ņśłņāü ļÉ£ļŗż.

5. Ļ░Ģņóģļ│ä, Metalļ│ä Flux Cored Wire Ļ░£ļ░£ ļÅÖĒ¢ź

5.1 ņŚ░Ļ░Ģ ļ░Å Ļ│ĀņןļĀźĻ░Ģ

ņØ╝ļ░ś ņŚ░Ļ░ĢņÜ® RutileĻ│ä ņÜ®ņĀæņ×¼ļŻīļŖö ņĀ£ņĪ░ņé¼ļ│äļĪ£ ņ░©ļ│äĒÖö ļ░Å ņĄ£ņĀüĒÖöĻ░Ć ļÉśņ¢┤ ņ׳Ļ│Ā, AWS A5.20 E71T-12X-JņØś ĻĘ£Ļ▓®ņ£╝ļĪ£ -46┬░CĻ╣īņ¦Ć ņČ®Ļ▓®ņØĖņä▒ņØä ņĢłņĀĢņĀüņ£╝ļĪ£ ļ¦īņĪ▒ņŗ£ĒéżļŖö ņÜ®ņĀæņ×¼ļŻīĻ░Ć ņĀüņÜ®ļÉśĻ│Ā ņ׳ļŗż. ņĄ£ĻĘ╝ Ļ▒┤ņäżņÜ®ņ£╝ļĪ£ ĒĢ┤ņÖĖļź╝ ļ╣äļĪ»ĒĢśņŚ¼ ĻĄŁļé┤ņŚÉļÅä ļé┤ņ¦äĻĘ£Ļ▓®ņØĖ AWS D1.8 Seismic Supplementļź╝ ļ¦īņĪ▒ĒĢśļŖö ņÜ®ņĀæņ×¼ļŻīļź╝ ņÜöĻĄ¼ĒĢśĻ│Ā ņ׳ņ£╝ļ®░, ņØ┤ļź╝ ļ│┤ņ”ØĒĢśļŖö AWS A5.20 E71T-9X-J FCWĻ░Ć ĒÖĢļīĆ ņĀüņÜ®ļÉĀ ņĀäļ¦ØņØ┤ļŗż.

ņ╗©ĒģīņØ┤ļäłņäĀņØś ņ┤łļīĆĒśĢĒÖö(20,000TEU ņØ┤ņāü)ņŚÉ ļö░ļØ╝ ĒĢśņżæņØä Ļ░Ćņן Ēü¼Ļ▓ī ļ░øļŖö Hatch CoamingļČĆņ£äņŚÉņä£ļŖö ļæÉĻ╗ś 80mmt ņØ┤ņāüņØś EH47 ĻĘ╣ĒøäĒīÉ Ļ░Ģņ×¼Ļ░Ć ņé¼ņÜ®ļÉśĻ│Ā16), -10┬░C CTOD(Crack Tip Opening Displacement) ņä▒ļŖźņØä ņÜöĻĄ¼ĒĢśņŚ¼ ņØ┤ļź╝ ļ¦īņĪ▒ĒĢśļŖö AWS A5.29 E81T1- K2XņØś FCWĻ░Ć ņĀüņÜ®ļÉśĻ│Ā ņ׳Ļ│Ā, Ē¢źĒøä CTOD ņä▒ļŖźņØä ļ¦īņĪ▒ĒĢśļŖö ļŹö ļåÆņØĆ Ļ░ĢļÅäņØś ņÜ®ņĀæņ×¼ļŻī ņłśņÜöĻ░Ć ņśłņāü ļÉ£ļŗż.

5.2 Low Alloy Ļ│ä

5.2.1 ņĀĆņś©ņÜ®Ļ░Ģ

ņĀĆņś©ņÜ®Ļ░ĢņØĆ ĻĘ╝ĒĢ┤ ļ░Å ņś©, ņŚ┤ļīĆ ņ¦ĆņŚŁ ĒĢ┤ņ¢æņŚÉņä£ņØś ņ×ÉņøÉ ņ▒äĻĄ┤ņØś ĒĢ£Ļ│äļĪ£ ņŗ¼ĒĢ┤ ļ░Å ĒĢ£ļף ņ¦ĆņŚŁņ£╝ļĪ£ ĻĘĖ ļ▓öņ£äĻ░Ć ĒÖĢļīĆļÉ©ņŚÉ ļö░ļØ╝ Ļ│ĀĻ░ĢļÅä, Ļ│ĀņØĖņä▒ņØä ņÜöĻĄ¼ĒĢśļ®┤ņä£ļÅä Ļ░Ģņ×¼ņØś ļæÉĻ╗śļŖö ļŹöņÜ▒ ņ¢ćņĢäņ¦ĆĻ│Ā ņ׳ņ£╝ļ®░, ņČ®Ļ▓®ņØĖņä▒Ļ│╝ CTOD ņä▒ļŖźņØä ļ│┤ņ”ØĒĢśĻĖ░ ņ£äĒĢ£ ļ░®Ē¢źņ£╝ļĪ£ ņ¦ĆņåŹņĀüņØĖ Ļ░Ģņ×¼ Ļ░£ļ░£ņØ┤ ņØ┤ļŻ©ņ¢┤ņ¦ĆĻ│Ā ņ׳ļŗż.

ņĀĆņś©ņÜ®Ļ░Ģ FCWļÅä Ļ░Ģņ×¼Ļ░£ļ░£Ļ│╝ ļŹöļČłņ¢┤ ņĀĆņś© ņČ®Ļ▓®ņØĖņä▒Ļ│╝ CTODļź╝ ļ│┤ņ”ØĒĢśļŖö ļ░®Ē¢źņ£╝ļĪ£ Ļ░£ļ░£ļÉśĻ│Ā ņ׳ņ£╝ļ®░, ĒĢ┤ņ¢æĻĄ¼ņĪ░ļ¼╝ņÜ® Ļ░Ģņ×¼ņØś Ļ▓ĮņÜ░ -40┬░C CTODņÜöĻĄ¼ ņä▒ļŖźņØä ļ¦īņĪ▒ĒĢśļŖö AWS A5.29 E91T1-Ni2X FCWĻ░Ć ņāüņÜ®ĒÖö ļÉśņŚłĻ│Ā, Ēśäņ×¼ļŖö -60┬░Cļź╝ ļ│┤ņ”ØĒĢśĻĖ░ ņ£äĒĢ£ ņÜ®ņĀæņ×¼ļŻīĻ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż. ņĢäļל Table 120)ņŚÉ -40┬░C CTOD ņä▒ļŖź Ļ░Ģņ×¼ņØś ņÜöĻĄ¼ ĒŖ╣ņä▒Ļ│╝ ņĄ£ņåī CTODņÜöĻĄ¼ņ╣ś(Ļ░Æ)ņØä ļéśĒāĆļé┤ņŚłļŗż.

Table┬Ā1

Target properties for the developed steel

5.2.2 ļé┤ņŚ┤Ļ░Ģ

ļé┤ņŚ┤Ļ░ĢņÜ® ņÜ®ņĀæņ×¼ļŻīļŖö ņĀüņÜ®ļČĆņ£äņŚÉ ļö░ļØ╝ ņÜ®ņĀæļČĆņØś ņČ®Ļ▓®ņä▒ļŖź, Step Cooling Test21), X-factor22)Ļ░ÆņØä ņÜöĻĄ¼ĒĢśĻ│Ā ņ׳ļŗż. ņØ┤ņ▓śļ¤╝ Ļ╣īļŗżļĪ£ņÜ┤ ņÜöĻĄ¼ņé¼ĒĢŁņØä ļ¦īņĪ▒ņŗ£ĒéżĻĖ░ ņ£äĒĢ┤ Ēśäņ×¼Ļ╣īņ¦Ć SMAWņÖĆ GTAW, GMAWņØś ņÜ®ņĀæĒöäļĪ£ņäĖņŖżĻ░Ć ņĀüņÜ®ļÉśņ¢┤ ņÖöļŗż. FCAWņØś Ļ▓ĮņÜ░ MCWņÖĆ ņŚ╝ĻĖ░ņä▒Ļ│äņØś FCWĻ░Ć ņØ╝ļČĆ ņāüņÜ®ĒÖö ļÉśņ¢┤ ņ׳ņ£╝ļéś ņĀäņ×ÉņäĖ ņÜ®ņĀæņä▒ņØä ĒÖĢļ│┤ĒĢĀ ņłś ņŚåĻ│Ā, MCWļŖö ļ│┤ĒśĖĻ░ĆņŖżļĪ£ Ar ļśÉļŖö Ēś╝ĒĢ®Ļ░ĆņŖżļź╝ ņé¼ņÜ®ĒĢ┤ņĢ╝ ĒĢśļ»ĆļĪ£ ņé¼ņÜ®ņāüņŚÉ ĒĢ£Ļ│äļź╝ Ļ░Ćņ¦ĆĻ│Ā ņ׳ļŗż. ņĢäņ¦üĻ╣īņ¦Ć RutileĻ│ä FCWļŖö ņØ┤ļ¤░ Ļ╣īļŗżļĪ£ņÜ┤ ņä▒ļŖźņØä ļ¦īņĪ▒ņŗ£Ēéżņ¦Ć ļ¬╗ĒĢ┤ ņĀ£ĒĢ£ņĀüņ£╝ļĪ£ ņĀüņÜ®ļÉśĻ│Ā ņ׳ļŗż.

ņØ╝ļ░śņĀüņ£╝ļĪ£ 375~575┬░C ļ▓öņ£äņŚÉņä£ Ļ▓░ņĀĢļ”ĮĻ│äņŚÉ P, Sb, Sn, AsņØś ļČłņł£ļ¼╝ņØ┤ ņ¦æņĀü, ĒÄĖņäØļÉśņ¢┤ ņ×ģĻ│äņŚÉņä£ ņØæņ¦æ(Co- hesive)ļĀź ņĀĆĒĢśļĪ£ ņ▓£ņØ┤ņś©ļÅäĻ░Ć ņāüņŖ╣(ņØĖņä▒ņĀĆĒĢś)ĒĢśņŚ¼ ļ░£ņāØĒĢśļŖö Temper EmbrittlementļŖö ņĢäļל ņŗØ (1)Ļ│╝ Ļ░ÖņØ┤ X-FactorļĪ£ Ēæ£ĻĖ░ ļÉśļ®░, P > As > Sb > SnņØś ņł£ņ£╝ļĪ£ ĒÖöĒĢÖņä▒ļČäņØś ņśüĒ¢źņØä ļ░øļŖöļŗż.

ņČ®Ļ▓®ņØĖņä▒, X-FactorņÖĆ Temper Embrittlementļź╝ ĒÅēĻ░ĆĒĢśļŖö Step Cooling Testļź╝ ļ¦īņĪ▒ĒĢśļŖö RutileĻ│ä FCWļŖö ņĢäņ¦ü ņāüņÜ®ĒÖö ļÉśņ¢┤ ņ׳ņ¦Ć ņĢŖņ¦Ćļ¦ī, SMAWļź╝ ļīĆņ▓┤ ņĀüņÜ®ĒĢśĻĖ░ ņ£äĒĢ£ FCWņØś Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż.

ļśÉĒĢ£, Ļ░Ģņ×¼ņØś Ļ░£ļ░£ņŚÉ ļ¦×ņČöņ¢┤ SA 335 P91, P92ņÖĆ ĒĢ©Ļ╗ś ņ┤łņ┤łņ×äĻ│äļź╝ ļäśņ¢┤ņä£ļŖö P122 Ļ░Ģņ×¼ņÜ® FCWĻ░Ć ņāüņÜ®ĒÖö ļÉśņ¢┤ ņ׳ņ¦Ćļ¦ī, X-Factor ļ¦īņØä ņÜöĻĄ¼ĒĢśļŖö ļČĆņ£äņŚÉ ĒĢ£ņĀĢņĀüņ£╝ļĪ£ ņé¼ņÜ®ļÉśĻ│Ā ņ׳Ļ│Ā Ē¢źĒøä ļé┤ņŚ┤Ļ░Ģņ×¼ ņåīņ×¼ņØś Ļ│ĀĻĖēĒÖöņŚÉ ļö░ļØ╝ ņØ┤ļōż Ļ░Ģņ×¼ņÜ® FCWņØś ņłśņÜöļŖö ņ”ØĻ░ĆĒĢĀ Ļ▓āņ£╝ļĪ£ ņĀäļ¦Ø ļÉ£ļŗż.

5.2.3 ļé┤Ēøäņä▒, ļé┤ņŗØĻ░Ģ

ļé┤Ēøäņä▒Ļ░ĢņØ┤ļ×Ć P(ņØĖ), Cr(Ēü¼ļĪ¼), Ni(ļŗłņ╝ł), Cu(ĻĄ¼ļ”¼)ļō▒ņØś ĒĢ®ĻĖłņøÉņåīļź╝ ņ▓©Ļ░ĆĒĢśņŚ¼ ĻĖłņåŹĒæ£ļ®┤ņŚÉ ļ│┤ĒśĖņĖĄņØä ĒśĢņä▒ĒĢśļ»ĆļĪ£ņŹ© ļīĆĻĖ░, ļ╣ä, ĒĢ┤ņłś ļ░Å ĒÖ®ņé░ ļō▒ņŚÉ ņØśĒĢ£ ļīĆĻĖ░ļČĆņŗØņØä ņ¢ĄņĀ£ĒĢśņŚ¼ ļČĆņŗØņåŹļÅäĻ░Ć ļ│┤ĒåĄĻ░ĢņØś ņłśļČäņØś 1ņØ┤ĒĢśĻ░Ć ļÉśļÅäļĪØ ĒĢ£ ņĀĆĒĢ®ĻĖłĻ░ĢņØä ļ¦ÉĒĢ£ļŗż. ļīĆĒæ£ņĀüņ£╝ļĪ£ Ļ│ĀP-Cr-CuĻ│äņÖĆ Cr-CuĻ│äņØś Ļ░ĢņóģņØ┤ ņŻ╝ņóģņØä ņØ┤ļŻ©Ļ│Ā ņ׳ļŗż. ņØ┤ļōż Ļ░Ģņ×¼ņØś ņÜ®ņĀæņ×¼ļŻīļĪ£ļŖö SMAW ĒöäļĪ£ņäĖņŖżņÜ® AWS A5.9 E7018-W1Ļ│╝ E8018- W2Ļ░Ć ņŻ╝ļĪ£ ņé¼ņÜ®ļÉśņŚłņ£╝ļéś, AWS A5.29 E81T1-W2ņØś FCWĻ░Ć ņāüņÜ®ĒÖö ļÉśņ¢┤ SMAWļź╝ ļīĆņ▓┤ ņĀüņÜ®ĒĢśĻ│Ā ņ׳ļŗż.

ļśÉĒĢ£, ĒÖ®ņé░ ļ░Å ņŚ╝ņé░ņŚÉ Ļ▓¼ļööļŖö ļ│ĄĒĢ®ļČĆņŗØ Ļ░Ģņ×¼ņÖĆ ņÜ®ņĀæņ×¼ļŻī Ļ░£ļ░£ņØ┤ ņĄ£ĻĘ╝ ĻĄŁļé┤ņŚÉņä£ ņ¦äĒ¢ē ļÉśņŚłņ£╝ļ®░ Ļ▒┤ņäż, ļ░£ņĀäņäżļ╣äņÜ®ņ£╝ļĪ£ Covered ElectrodeņÖĆ FCWĻ░Ć ņāüņÜ®ĒÖö ļÉśņ¢┤ ņ׳ļŗż.

5.2.4 Stainless Steel

ņŖżĒģīņØĖļ”¼ņŖżĻ░ĢņØĆ ĻĄ¼ņĪ░ļ¼╝ņØś Ļ▓Įļ¤ēĒÖö ļ░Å Ļ░ĆĒś╣ĒĢ£ ņĪ░Ļ▒┤ņØä ļ¦īņĪ▒ĒĢśļŖö Ļ░Ģņ×¼ņØś ņĀüņÜ®ņØä ĒåĄĒĢ£ ņłśļ¬ģ ņŚ░ņןņØä ņ£äĒĢ┤ ļŗżĻ░üļÅäņØś ņäżĻ│äĻ░Ć ņŗ£ļÅäļÉśĻ│Ā ņ׳ņ£╝ļ®░, ĻĘĖņŚÉ ļö░ļØ╝ Ļ░Ģņ×¼ņØś Ļ░£ļ░£ļÅä ĻĖ░ņĪ┤ AusteniteĻ│ä Stainless Steel(ņØ┤ĒĢś STS)ņØĖ STS 316LņŚÉņä£ Duplex Stainless Steel(ņØ┤ĒĢś DSS)ņÖĆ Super Duplex Stainless Steel(ņØ┤ĒĢś SDSS)ļĪ£ ņ¦äĒ¢ēļÉśņŚłĻ│Ā, ņĄ£ĻĘ╝ņŚÉņä£ļŖö ļé┤ņŗØņä▒ņØ┤ ļŹöņÜ▒ Ē¢źņāüļÉ£ Super Austenite Stainless Steel (ņØ┤ļØ╝ SASS)Ļ│╝ Hyper Duplex Stainless Steel(ņØ┤ĒĢś HDSS)ļĪ£ ļ░£ņĀäĒĢśĻ│Ā ņ׳ļŗż.

Duplex Stainless SteelņØĆ ļåÆņØĆ ņØĖņןĻ░ĢļÅäņÖĆ ĒĢ┤ņłśņŚÉņä£ ņÜ░ņłśĒĢ£ ļé┤Ļ│ĄņŗØ(Pitting Corrosion) ņĀĆĒĢŁņä▒ ļ░Å ņÜ░ņłśĒĢ£ ļé┤ĻĄ¼ņä▒ņØä ĒŖ╣ņ¦Ģņ£╝ļĪ£ ļŗ┤ņłśņäżļ╣ä, ĒĢ┤ņ¢æĻĄ¼ņĪ░ļ¼╝ņØä ļ╣äļĪ»ĒĢśņŚ¼ ĻĖ░ņĪ┤ STS 316LņØ┤ ņØ┤ņÜ®ļÉśļŹś ņśüņŚŁņŚÉ ĒÖ£ļ░£Ē׳ ļīĆņ▓┤ ņĀüņÜ®ļÉśĻ│Ā ņ׳ļŗż. ĒŖ╣Ē׳ ĒĢ┤ņ¢æĒöīļ×£ĒŖĖĻ│Ąņé¼ņŚÉ DSS ņÜ®ņĀæņ×¼ļŻīļź╝ ņĀüņÜ®ĒĢśĻĖ░ ņ£äĒĢ┤ņä£ļŖö -46┬░CņØś ņČ®Ļ▓®Ļ░ÆņØä ļ│┤ņ”ØĒĢ┤ņĢ╝ ĒĢśļŖöļŹ░, ĻĖ░ņĪ┤ RutileĻ│ä FCWļŖö -46┬░CņØś ņČ®Ļ▓®Ļ░Æ ļ│┤ņ”ØņŚÉ ņāüļŗ╣ĒĢ£ ņ¢┤ļĀżņøĆņØä Ļ░Ćņ¦ĆĻ│Ā ņ׳ņŚłļŗż. ĻĘĖļ¤¼ļéś ņĄ£ĻĘ╝ -46┬░C ņĀĆņś© ņČ®Ļ▓® ņØĖņä▒ņØä ļ¦īņĪ▒ĒĢśļŖö AWS A5.22 E2209T1-1ņØś RutileĻ│ä ņĀäņ×ÉņäĖņÜ® FCWĻ░Ć ĻĄŁļé┤ņŚÉņä£ Ļ░£ļ░£ļÉśņ¢┤ ņØ╝ļČĆ ļīĆĒśĢņĪ░ņäĀņåīņŚÉ WPS(Welding Procedure Specification) ļō▒ņ×¼Ļ░Ć ņÖäļŻīļÉśņŚłļŗż.

ļŹöļČłņ¢┤ Ļ│ĄņŗØ ņĀĆĒĢŁ ļŗ╣ļ¤ē ņ¦Ćņłś(Pitting Resistance Equi- valent Number, PREN, ņŗØ (2)) Ļ░Ć ņĄ£ņåī 45~50ņØ┤ņāüņØĖ SDSSņØĖ UNS S32254, S32654ņØś ņłśņÜöĻ░Ć ņ”ØĻ░ĆĒĢśĻ│Ā ņ׳ņ£╝ļ®░, ņØ┤ļź╝ ņ£äĒĢ£ SDSSņÜ® FCWĻ░Ć ņĄ£ĻĘ╝ ĻĄŁļé┤ņŚÉņä£ Ļ░£ļ░£ ļ░Å ņāüņÜ®ĒÖö ļÉśņ¢┤ ņĀüņÜ® ņżæņŚÉ ņ׳ļŗż.

(2)

SASSļŖö ļåÆņØĆ PRENĻ░ÆņØä Ļ░Ćņ¦Ćļ®░, NiĻ│ä ĒĢ®ĻĖł ļīĆļ╣ä ņĀĆļĀ┤ĒĢśĻ│Ā ļÅÖļō▒ĒĢ£ ņłśņżĆņØś ļé┤Ļ│ĄņŗØ ĒŖ╣ņä▒ņØä Ļ░Ćņ¦Ćļ»ĆļĪ£ ņøÉņ×ÉļĀź ļ░£ņĀäņåīņØś ĒĢ┤ņłś Ļ│äĒåĄ, ļŗ┤ņłś ņäżļ╣ä, ĒÖöļĀźļ░£ņĀäņåīņØś ĒāłĒÖ®ņäżļ╣ä ļ░Å ņäØņ£ĀĒÖöĒĢÖ ņäżļ╣ä ļō▒ņŚÉ ņĀüņÜ®ĒĢśĻ│Ā ņ׳ļŗż. ĻĘĖļ¤¼ļéś ņÜ®ņĀæ ņŗ£ ļ░£ņāØĒĢśļŖö ļé┤ņŗØņä▒ ņĀĆĒĢś, ĻĘĀņŚ┤ļ░£ņāØ ļō▒ņØś ļ¼ĖņĀ£ļĪ£ ņØĖĒĢśņŚ¼ NiĒĢ®ĻĖłĻ│äņØĖ Inconel 625ļź╝ ņÜ®ņĀæņ×¼ļŻīļĪ£ ņŻ╝ļĪ£ ņé¼ņÜ®ĒĢśĻ│Ā ņ׳ņ£╝ļ®░, Ē¢źĒøä SASSĻ│ä Ļ░Ģņ×¼ņØś ņåīņÜöļ¤ēņØ┤ ļŹöņÜ▒ ņ”ØĻ░ĆĒĢĀ Ļ▓ĮņÜ░ SASSņÖĆ ļÅÖļō▒ĒĢ£ ņä▒ļČäĻ│äļź╝ Ļ░Ćņ¦ĆļŖö FCWņØś Ļ░£ļ░£ņŚÉ ļīĆĒĢ£ ņłśņÜöĻ░Ć ņ”ØĻ░ĆĒĢĀ Ļ▓āņ£╝ļĪ£ ņśłņāü ļÉ£ļŗż.

ļ¦łņ¦Ćļ¦ēņ£╝ļĪ£ 400┬░C ņØ┤ņāüņØś Ļ│Āņś©ņÜ®, 500┬░C ņØ┤ņāüņØś ĒøäņŚ┤ņ▓śļ”¼ļź╝ ņŗżņŗ£ĒĢśļŖö Ļ░Ģņ×¼ņÜ®ņ£╝ļĪ£ ņĀüņÜ®ļÉśļŖö STS FCWņØś Ļ▓ĮņÜ░ Bi ĒĢ©ņ£Āļ¤ēņØä 20ppm ņØ┤ĒĢśļĪ£ ņĀ£ĒĢ£ĒĢśļÅäļĪØ AWS A2.2ņŚÉ ļ¬ģĻĖ░ļÉśņ¢┤ ņ׳ļŗż. BiļŖö FCWņØś ņŖ¼ļלĻĘĖ ļ░Ģļ”¼ņä▒ņØä Ļ░£ņäĀņŗ£ņ╝£ ņŻ╝ļŖö ņøÉņåīļĪ£ ņØ╝ļ░śņĀüņ£╝ļĪ£ ļ¦ÄņØ┤ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ņ£╝ļéś, ņÜ®ņĀæĒøäņŚ┤ņ▓śļ”¼ļÅÖņĢł BiņØś ņ×ģĻ│äĒÖĢņé░ņŚÉ ņØśĒĢ┤ ņ×¼ņŚ┤ĻĘĀņŚ┤ ļ░£ņāØņØś ņøÉņØĖņ£╝ļĪ£ ņ×æņÜ®ĒĢśĻ▓ī ļÉ£ļŗż23). ļ»ĖĻĄŁĻ│╝ ņ£Āļ¤Į ļō▒ņØś ņäĀņ¦äĻĄŁņŚÉņä£ļŖö ņÜ®ņĀæņ×¼ļŻīņØś Bi ĒĢ©ļ¤ēņØä Ēæ£ĻĖ░ĒĢśļÅäļĪØ ĻČīņןĒĢśĻ│Ā ņ׳ņ£╝ļ®░, Bi Free ņÜ®ņĀæņ×¼ļŻīņŚÉ ļīĆĒĢ£ Ļ┤Ćņŗ¼ņØ┤ ļåÆņĢäņ¦ĆĻ│Ā ņ׳ļŗż. ĻĄŁļé┤ņŚÉļÅä ņØ┤ļ»Ė ņāüņÜ®ĒÖöļÉ£ Bi free FCWĻ░Ć ņāØņé░ ļÉśĻ│Ā ņ׳ņ£╝ļ®░, Biļź╝ ņ▓©Ļ░ĆĒĢśņ¦Ć ņĢŖĻ│Āņä£ļÅä ļÅÖļō▒ĒĢ£ ņŖ¼ļלĻĘĖ ļ░Ģļ”¼ņä▒ņØä ĒÖĢļ│┤ĒĢĀ ņłś ņ׳ļŖö ĻĖ░ņłĀĻ░£ļ░£ņØä ņ¦äĒ¢ē ņżæņØ┤ļŗż.

5.2.5 ļ╣äņ▓ĀĻĖłņåŹ

Al, Mg, Cu, TiĒĢ®ĻĖłĻ│äņÖĆ Ļ░ÖņØĆ ļ╣äņ▓ĀĻĖłņåŹņØś ņÜ®ņĀæņŚÉļŖö ņĢäņ¦üĻ╣īņ¦Ć ņŻ╝ņÜö ņÜ®ņĀæ ĒöäļĪ£ņäĖņŖżļĪ£ Solid WireņØś ņÜ®ņĀæņ×¼ļŻīļź╝ ņé¼ņÜ®ĒĢśļŖö GTAWņÖĆ GMAWļź╝ ņĀüņÜ®ĒĢśĻ│Ā ņ׳ņ£╝ļ®░, GMAWļŖö MIGņÜ®ņĀæņØ┤ ņŻ╝ļź╝ ņØ┤ļŻ¼ļŗż.

ļśÉĒĢ£, Al, CuĒĢ®ĻĖłĻ│äņØś Ļ▓ĮņÜ░ ņåīļ¤ēņØś SMAW ĒöäļĪ£ņäĖņŖżĻ░Ć ņĀüņÜ®ļÉśĻ│Ā ņ׳ņ¦Ćļ¦ī, Ēśäņ×¼Ļ╣īņ¦Ć Solid Wireļź╝ ļīĆņ▓┤ĒĢśĻ│Āņ×É ĒĢśļŖö ņŗ£ņןņØś ņÜöĻĄ¼Ļ░Ć ņŚåņ¢┤ ņØ┤ļōż ļ╣äņ▓ĀĻĖłņåŹņÜ® FCWņØś Ļ░£ļ░£ņØĆ ļŗ©ĻĖ░Ļ░äņŚÉ ņØ┤ļŻ©ņ¢┤ ņ¦Ćņ¦ĆļŖö ņĢŖņØä ņĀäļ¦ØņØ┤ļŗż.

NiĒĢ®ĻĖłĻ│äļŖö Ēśäņ×¼Ļ╣īņ¦Ć ņŻ╝ņÜö ņÜ®ņĀæ ĒöäļĪ£ņäĖņŖżļĪ£ SMAWņÖĆ GTAW, GMAWņØś MIGĻ░Ć ņĀüņÜ®ļÉśĻ│Ā ņ׳ņ£╝ļéś, SAMWņÖĆ GTAWļŖö ņāØņé░ņä▒ņØ┤ ļé«Ļ│Ā, MIGņØś Ļ▓ĮņÜ░ ņĀäņ×ÉņäĖ ņÜ®ņĀæņØ┤ ņ¢┤ļĀĄņÜ░ļ®░, ĻĖ░Ļ│Ą ļ░£ņāØļźĀņØ┤ ļåÆņĢä ņé░ņŚģĒśäņןņŚÉņä£ļŖö ļ╣äņÜ®Ļ│╝ ĒÆłņ¦łļ¼ĖņĀ£ļĪ£ ņ¢┤ļĀżņøĆņØä Ļ▓¬Ļ│Ā ņ׳ļŗż. ņØ┤ļź╝ ĒĢ┤Ļ▓░ĒĢśĻĖ░ ņ£äĒĢ┤ RutileĻ│äņØś ņĀäņ×ÉņäĖņÜ® FCWĻ░Ć Ļ░£ļ░£ ļ░Å ņĀüņÜ®ļÉśĻ│Ā ņ׳ņ£╝ļ®░ ĻŠĖņżĆĒĢ£ ņŗ£ņןņä▒ņןņØ┤ ĻĖ░ļīĆļÉ£ļŗż. ĒŖ╣Ē׳ ĒÄäņŖż(Pulse) ĻĖ░ļŖźņØä ņé¼ņÜ®ĒĢśņ¦Ć ņĢŖĻ│Āņä£ļÅä ņĀäņ×ÉņäĖ ņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢśĻ│Ā, ņØ╝ļ░śņĀüņ£╝ļĪ£ GMAWņØś 1.5~2ļ░░, SAMWņŚÉ ļ╣äĒĢ┤ 2~3ļ░░ņØś ļåÆņØĆ ņÜ®ņ░®ņåŹļÅäļź╝ Ļ░Ćņ¦ł ņłś ņ׳ļŗż. ļśÉĒĢ£ ļ│┤ĒśĖĻ░ĆņŖżļĪ£ Ar, CO2, Ēś╝ĒĢ®Ļ░ĆņŖż ļ¬©ļæÉ ņé¼ņÜ®ĒĢĀ ņłś ņ׳ņ¢┤ ĒÖ£ņÜ®ņä▒ņØ┤ ļŹöņÜ▒ ļåÆļŗż24). Table 2ņŚÉ ņāüņÜ®ĒÖö ļÉśņ¢┤ ņ׳ļŖö NiĻ│ä FCWņØś ņóģļźśļź╝ ļéśĒāĆļé┤ņŚłļŗż.

Table┬Ā2

List of commercialized Ni alloy Flux Cored Wire

6. Ļ▓░ ļĪĀ

ļ│Ė ļģ╝ļ¼ĖņŚÉņä£ļŖö Flux Cored WireņØś ņĄ£ņŗĀĻĖ░ņłĀ ļÅÖĒ¢źņŚÉ ļīĆĒĢ┤ ņåīĻ░£ ĒĢśņśĆļŗż.

ņĀ£ņĪ░ĻĖ░ņłĀ ņĖĪļ®┤ņŚÉņä£ Seamless type FCWļŖö ĻĖ░ņĪ┤ Folded Type FCWņŚÉ ļ╣äĒĢ┤ ņŚ¼ļ¤¼Ļ░Ćņ¦Ć ņןņĀÉņØä Ļ░ĆņĪīņ¦Ćļ¦ī ļ╣äņÜ®ņĀüņØĖ ļ¼ĖņĀ£ļĪ£ ļ▓öņÜ®ĒÖöĻ░Ć ļÉśņ¦Ć ņĢŖĻ│Ā ņ׳ņ¢┤, ņāØņé░ļ╣äņÜ®ņØä ļé«ņČöĻĖ░ ņ£äĒĢ£ ņŚ░ĻĄ¼ļōżņØä ņ¦äĒ¢ēĒĢśĻ│Ā ņ׳ļŗż. ļīĆĒæ£ņĀüņØĖ ĻĖ░ņłĀļĪ£ ņØ┤ņżæĻ┤Ć ĒśĢĒā£ļĪ£ ņĀ£ņ×æĒĢ£ Ēøä ņŗ¼ļČĆļź╝ ņÜ®ņĀæĒĢ©ņ£╝ļĪ£ņŹ© ņĢäĒü¼Ļ░Ć ņ¦üņĀæ ļé┤ļČĆ FluxņŚÉ ņśüĒ¢źņØä ļ»Ėņ╣śņ¦Ć ņĢŖĻ▓ī ĒĢśņŚ¼ ĻĖ░ņĪ┤ņØś ļ¼ĖņĀ£ņĀÉņØä Ļ░£ņäĀĒĢśĻ│Ā, ļ¼┤ļÅäĻĖłņØś ĒśĢĒā£ļĪ£ ļŹöņÜ▒ ņāØņé░ļ╣äņÜ®ņØä ļé«ņČś ĒöäļĪ£ņäĖņŖżļź╝ ņåīĻ░£ ĒĢśņśĆļŗż.

ļśÉĒĢ£, FCW typeļ│äļĪ£ļŖö RutileĻ│äņŚÉņä£ ĒøäņŚ┤ņ▓śļ”¼ Ēøä Ļ│ĀņØĖņä▒ņØä ļ¦īņĪ▒ņŗ£ĒéżĻĖ░ ņ£äĒĢ£ ĻĖ░ņłĀ Ļ░£ļ░£ņØ┤ ņ¦ĆņåŹņĀüņ£╝ļĪ£ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ņ£╝ļ®░, Ļ│ĀņåŹņÜ®ņĀæņÜ®ņ£╝ļĪ£ļŖö ņāØņé░ņä▒ Ē¢źņāüņØä ņ£äĒĢ┤ ņŗ▒ĻĖĆ ņśżĒåĀņ╝Ćļ”¼ņ¦Ć ņĀüņÜ®ņŗ£ ņÜ®ņĀæņåŹļÅä 100 cpmņØ┤ņāü, ĒŖĖņ£łĒāäĒģ£ 200 cpmĻ╣īņ¦Ć ņÜ®ņĀæĻ▓░ĒĢ© ņŚåņØ┤ ņÜ®ņĀæņØ┤ Ļ░ĆļŖźĒĢ£ ņ×¼ļŻīĻ░£ļ░£ņØ┤ ņØ┤ļŻ©Ļ│Ā ņ¦ĆĻ│Ā ņ׳ļŗż.

MCWļŖö ņ×ÉļÅÖņ░©ļČĆļČäņŚÉņä£ ļé┤ņŗØņä▒ņØä ĒÖĢļ│┤ĒĢśĻĖ░ ņ£äĒĢ┤ ņĢäņŚ░ļÅäĻĖłĻ░ĢĒīÉņ£╝ļĪ£ ļīĆņ▓┤ ļÉ©ņŚÉ ļö░ļØ╝ ĻĖ░ņĪ┤ ņåöļ”¼ļō£ ņÖĆņØ┤ņ¢┤ņØś Si island ĒśĢņä▒ņØä ļé«ņČöĻĖ░ ņ£äĒĢ£ ļ░®Ē¢źņ£╝ļĪ£ Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż.

Ļ░Ģņóģļ│ä ĒŖ╣ņ¦Ģņ£╝ļĪ£ -40┬░C CTODļź╝ ļäśņ¢┤ -60┬░CĻ╣īņ¦Ć CTODņä▒ļŖźņØä ļ│┤ņ”ØĒĢśļŖö ņ×¼ļŻīĻ░£ļ░£ņØ┤ ņ¦äĒ¢ē ņżæņØ┤ļ®░, ņŖżĒģīņØĖļ”¼ņŖżĻ░Ģ FCWļŖö ļé┤ļČĆņŗØ Ļ░Ģņ×¼ņØś Ļ│ĀĻĖēĒÖöņŚÉ ņØśĒĢ┤ ņŖłĒŹ╝ņśżņŖżĒģīļéśņØ┤ĒŖĖĻ│ä Ļ░£ļ░£ņØä ņ¦äĒ¢ē ņżæņØ┤ļŗż.

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print