1. ņä£ ļĪĀ

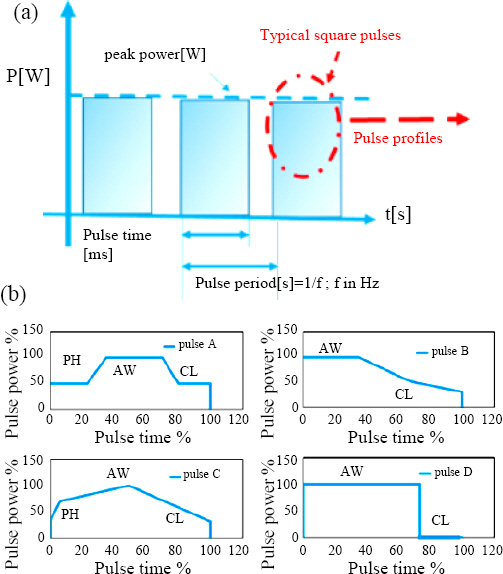

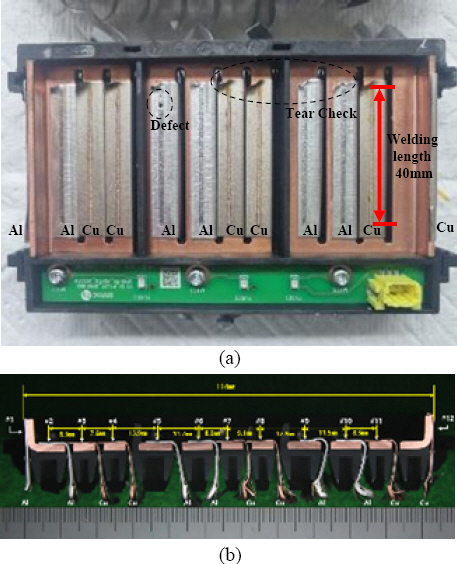

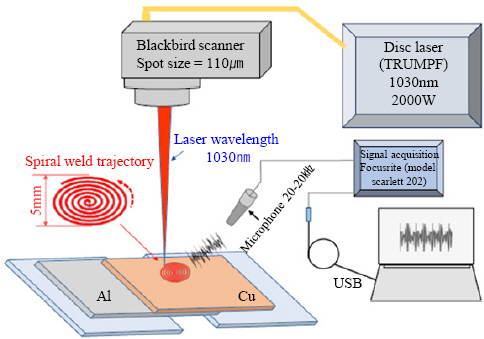

Fig.┬Ā1

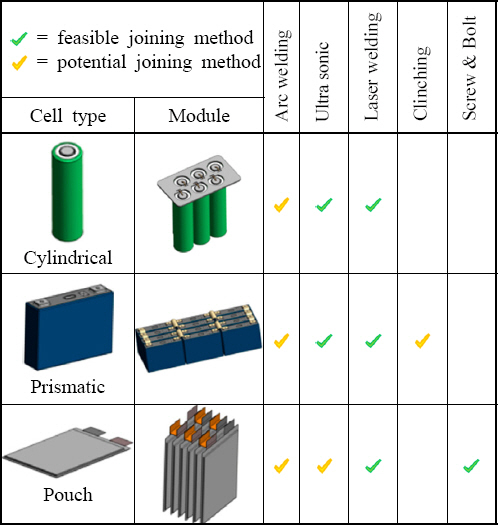

Table┬Ā1

2. ņĢīļŻ©ļ»ĖļŖäĻ│╝ ĻĄ¼ļ”¼ņØś ļĀłņØ┤ņĀĆ ņÜ®ņĀæņä▒

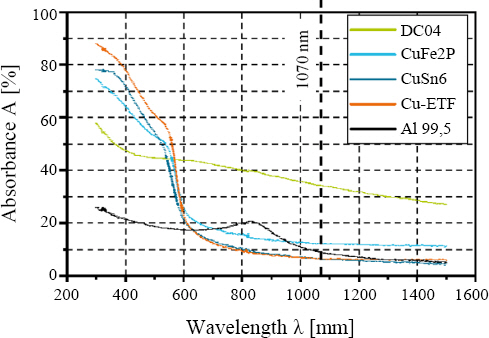

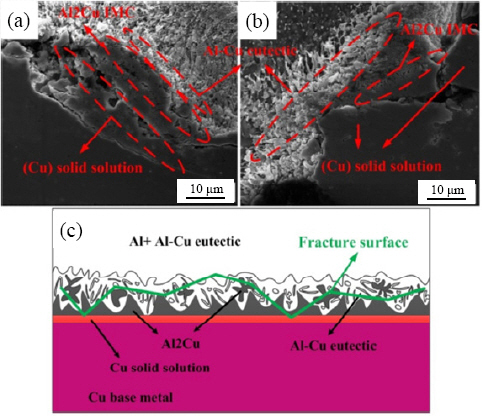

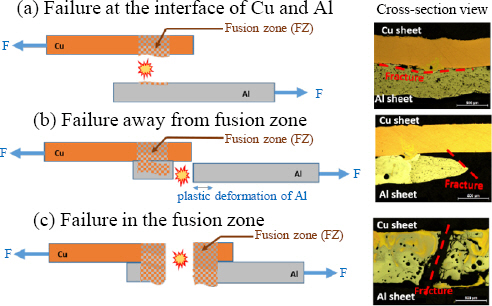

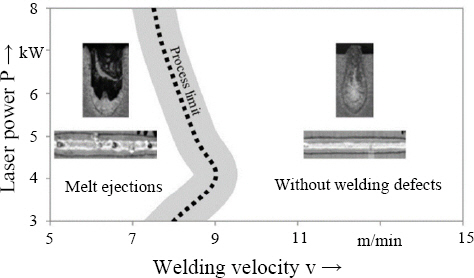

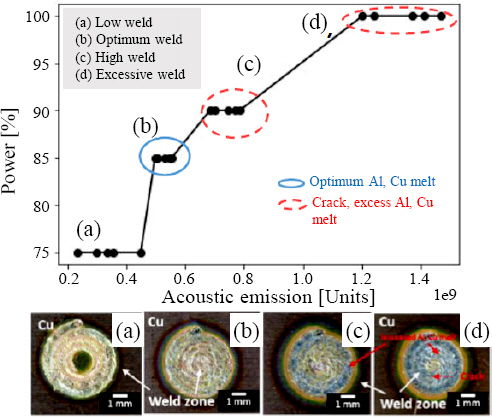

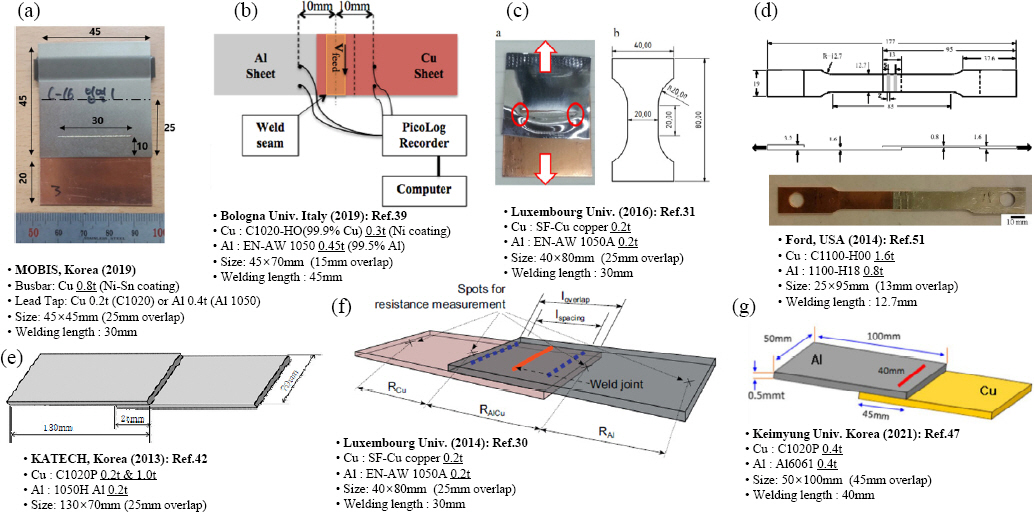

Fig.┬Ā2

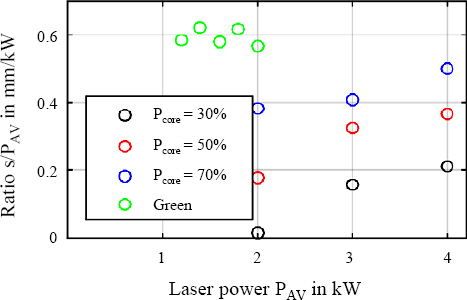

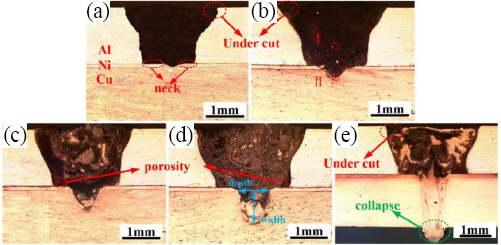

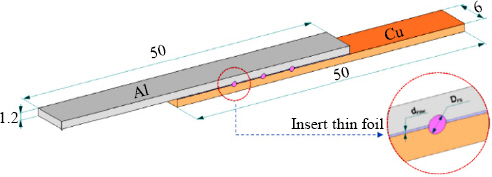

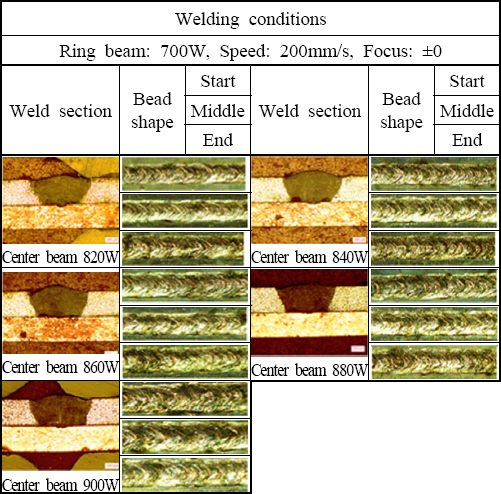

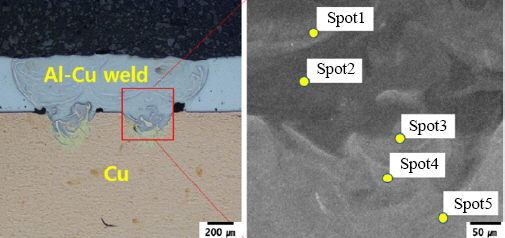

Fig.┬Ā3

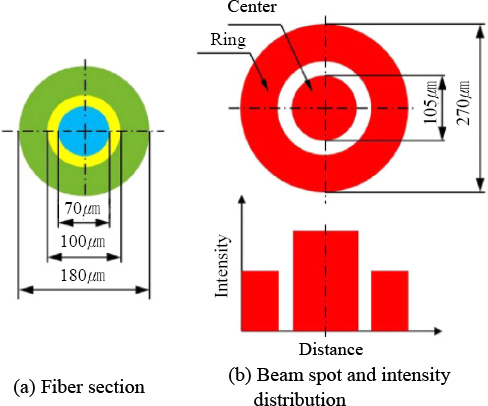

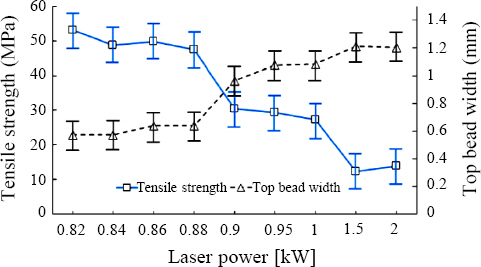

Fig.┬Ā4

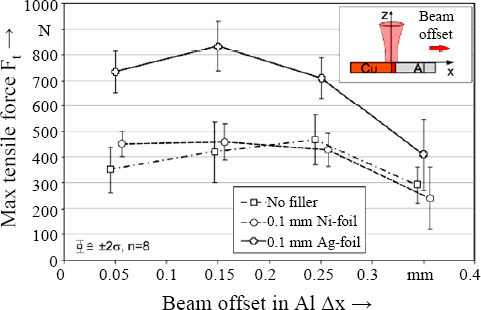

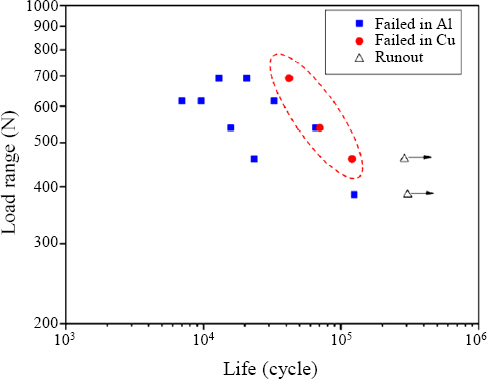

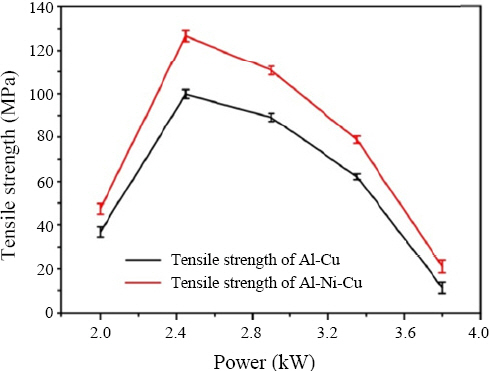

Fig.┬Ā6

3. ļĀłņØ┤ņĀĆ Ļ│ĄņĀĢņŚÉ ļö░ļźĖ ņÜ®ņĀæņä▒ ļ╣äĻĄÉ

3.1 ĒÄäņŖż ļĀłņØ┤ņĀĆ ņÜ®ņĀæ

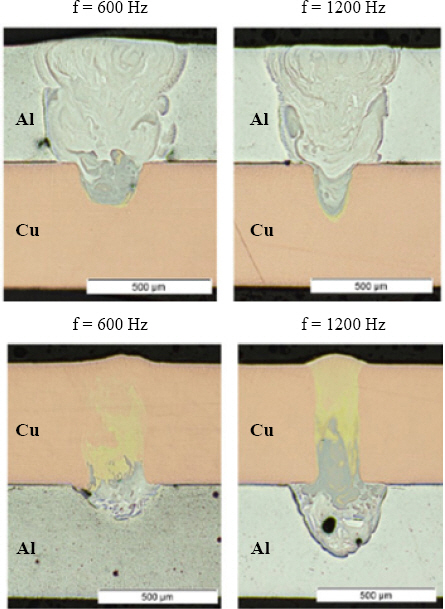

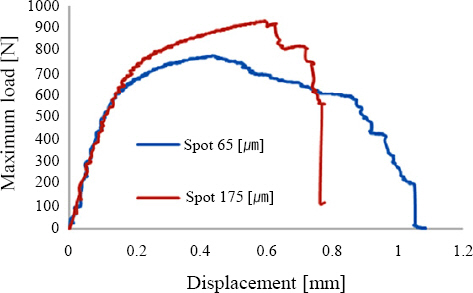

Fig.┬Ā8

Fig.┬Ā10

3.2 ņŗ▒ĻĖĆļ¬©ļō£ ļĀłņØ┤ņĀĆ ņÜ®ņĀæ

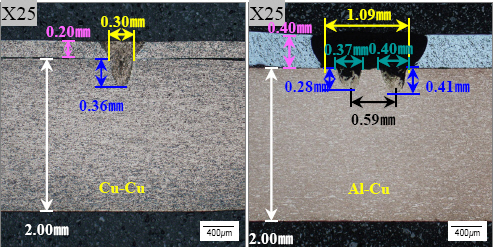

Fig.┬Ā11

Fig.┬Ā13

Fig.┬Ā14

3.3 ļ®ĆĒŗ░ļ¬©ļō£ ļĀłņØ┤ņĀĆ ņÜ®ņĀæ (CW)

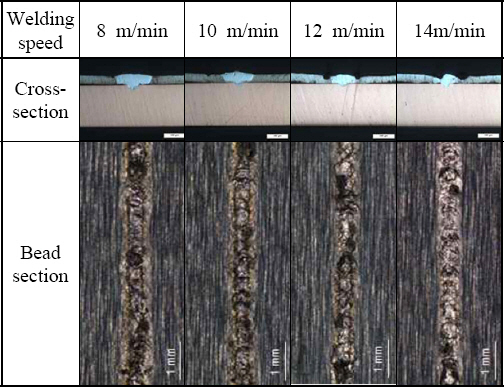

Fig.┬Ā15

Fig.┬Ā16

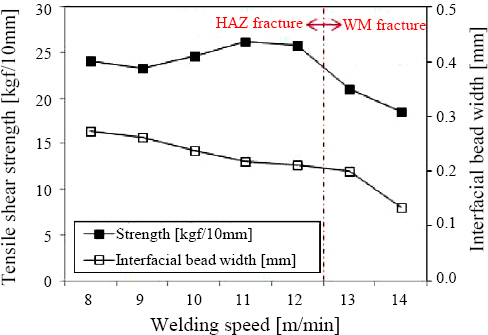

Fig.┬Ā18

Fig.┬Ā19

Fig.┬Ā22

Fig.┬Ā25

3.4 ĻĘĖļ”░ ļĀłņØ┤ņĀĆ ņÜ®ņĀæ

Fig.┬Ā28

4. ļĀłņØ┤ņĀĆ ņÜ®ņĀæļČĆņØś ĒÆłņ¦łĒÅēĻ░Ć

4.1 ņĀæĒĢ®ļČĆ ņØĖņן/ļé┤ĻĄ¼Ļ░ĢļÅä ĒÅēĻ░Ć

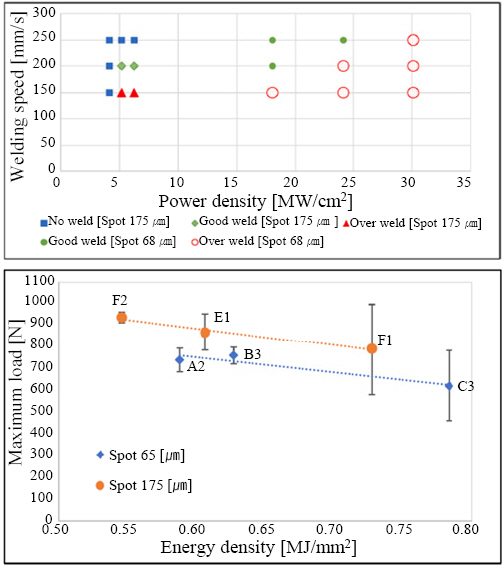

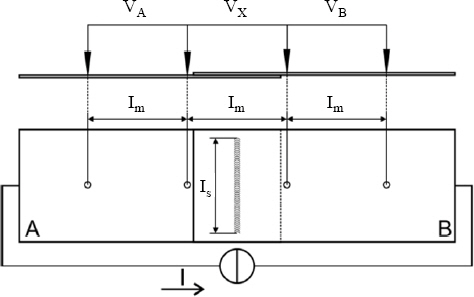

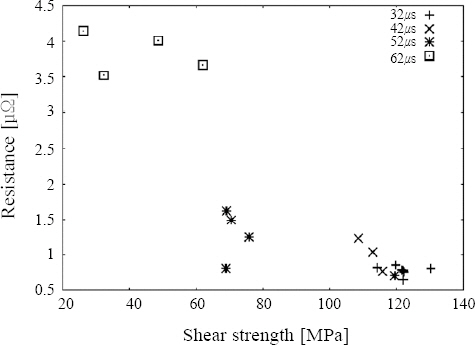

Fig.┬Ā30

Fig.┬Ā31

4.2 ņĀäĻĖ░ņĀäļÅäļÅä

Table┬Ā2

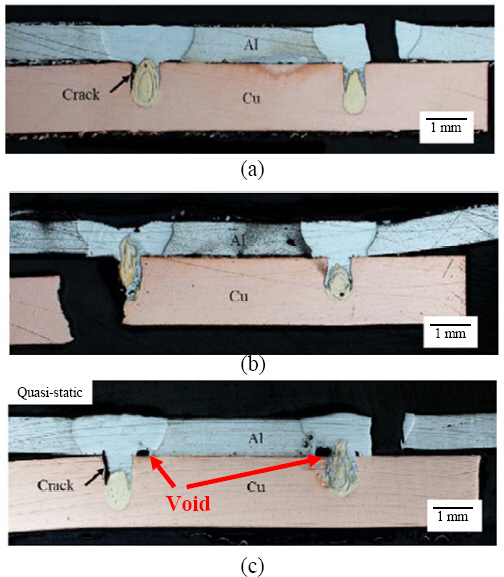

Fig.┬Ā33

Fig.┬Ā34

5. ļ▓äņŖżļ░ö ņĀ£ĒÆł ņÜ®ņĀæļČĆ ĒÆłņ¦ł ļČäņäØ

Fig.┬Ā35

6. Ļ▓░ ļĪĀ

1) AlĻ│╝ Cu Ļ░üĻ░üņØĆ ļ¬©ļæÉ ļĀłņØ┤ņĀĆņŚÉ ļīĆĒĢ£ ļé£ņÜ®ņĀæņä▒ ņ×¼ļŻīļĪ£ ļČäļźśļÉśļ®░, ņØ┤ļōż ņåīņ×¼ņØś ņØ┤ņóģņĀæĒĢ®ņØĆ ņÜ®ņĀæļČĆņŚÉ ļ░£ņāØĒĢśļŖö ņĘ©ņä▒ņØś ĻĖłņåŹĻ░äĒÖöĒĢ®ļ¼╝ļĪ£ ņØĖĒĢ┤ ņÜ░ņłśĒĢ£ ņÜ®ņĀæĒÆłņ¦łņØä ņ¢╗ļŖö Ļ▓āņØ┤ ņ¢┤ļĀĄļŗż. ļö░ļØ╝ņä£ ĒÜ©Ļ│╝ņĀüņØĖ ļĀłņØ┤ņĀĆ ņÜ®ņĀæņØä ņ£äĒĢ┤ņä£ļŖö ņŚÉļäłņ¦Ć ļ░ĆļÅä(ļ╣ö ņé¼ņØ┤ņ”ł), ņÜ®ņĀæ ņ×ģņŚ┤ļ¤ē, ļ╣ö ļ¬©ļōłļĀłņØ┤ņģś ļ░Å ļĀłņØ┤ņĀĆ Ēīīņן ļō▒ņØä Ļ│ĀļĀżĒĢśņŚ¼ ņØ┤ļ¤¼ĒĢ£ Ļ│ĄņĀĢļ│ĆņłśļōżņØ┤ ļ¬©ļæÉ ņĄ£ņĀüĒÖöļÉśņ¢┤ņĢ╝ ĒĢ£ļŗż.

2) AlĻ│╝ CuņØś ļĀłņØ┤ņĀĆņÜ®ņĀæņŚÉ ņĀüņÜ®ĒĢĀ ņłś ņ׳ļŖö Ļ│ĄņĀĢņØĆ ĒÄäņŖż ļĀłņØ┤ņĀĆ, ņŗ▒ĻĖĆļ¬©ļō£ ļĀłņØ┤ņĀĆ, Ļ│ĀņČ£ļĀź ļ®ĆĒŗ░ļ¬©ļō£ ļĀłņØ┤ņĀĆ ĻĘĖļ”¼Ļ│Ā ĻĘĖļ”░ ļĀłņØ┤ņĀĆļĪ£ ĻĄ¼ļČäĒĢĀ ņłś ņ׳ļŗż. ņØ┤ļōżņØś ņŚ░ĻĄ¼Ļ▓░Ļ│╝ļōżņØä Ļ▓ĆĒåĀĒĢ£ Ļ▓░Ļ│╝ ļ¬©ļæÉ Ļ│ĄņĀĢļ│ä ņןļŗ©ņĀÉņØ┤ ņĪ┤ņ×¼ĒĢśĻĖ░ ļĢīļ¼ĖņŚÉ ņ¢┤ļ¢ż Ļ│ĄņĀĢņØ┤ Ļ░Ćņן ņĀüĒĢ®ĒĢ£ Ļ▓āņØĖņ¦Ć ļ¬ģĒÖĢĒĢśĻ▓ī ņĀ£ņĢłĒĢśĻĖ░ļŖö ņ¢┤ļĀĄļŗż.

3) ļĀłņØ┤ņĀĆ ņÜ®ņĀæļČĆņØś ĒÆłņ¦łĒÅēĻ░ĆļŖö ļīĆļČĆļČä ņØĖņןĻ░ĢļÅä ļ░Å ņĀäĻĖ░ņĀäļÅäļÅä Ļ┤ĆņĀÉņŚÉņä£ ņŚ░ĻĄ¼Ļ░Ć ņ¦äĒ¢ēļÉśņŚłļŗż. ĻĘĖļ¤¼ļéś ņØ┤ņŚÉ ļīĆĒĢ£ ļ¬ģĒÖĢĒĢ£ ņŗ£ĒŚśĻĖ░ņżĆ ļ░Å Ēæ£ņżĆĒÖöļÉ£ ĻĘ£Ļ▓®ņØ┤ ņŚåĻĖ░ ļĢīļ¼ĖņŚÉ Ļ┤ĆļĀ© ĻĘ£Ļ▓®ņØś ņĀ£ņĀĢņØ┤ ņŗ£ĻĖēĒĢśļŗż. ļśÉĒĢ£, Al/Cu ņØ┤ņóģņĀæĒĢ®ļČĆņŚÉ ļīĆĒĢ£ Ēö╝ļĪ£ĒŖ╣ņä▒ņØś ļČäņäØ ļ░Å ĒÅēĻ░ĆĻĖ░ņżĆļÅä ļ╣Āļź┤Ļ▓ī ņżĆļ╣äļÉśņ¢┤ņĢ╝ ĒĢ£ļŗż.

4) ĻĄŁļé┤ ņ¢æņé░ ļ░░Ēä░ļ”¼ ļ¬©ļōłņØä ļīĆņāüņ£╝ļĪ£ Ēŗ░ņ¢┤ļŗżņÜ┤ ļČäņäØņØä ņŗżņŗ£ĒĢ£ Ļ▓░Ļ│╝, ņ¢æĒśĖĒĢ£ ņłśņżĆņØś ĒÆłņ¦łņØä ņ£Āņ¦ĆĒĢśĻ│Ā ņ׳ņØīņØ┤ ĒÖĢņØĖļÉśņŚłļŗż. ĻĘĖļ¤¼ļéś ļ│┤ļŗż ļåÆņØĆ ņłśņżĆņØś ĒÆłņ¦łļ│┤ņ”Ø ļ░Å ņāØņé░ņä▒ Ē¢źņāüņØä ņ£äĒĢ┤ņä£ļŖö ņŗĀļó░ņä▒ ņ׳ļŖö ņŗżņŗ£Ļ░ä ļĀłņØ┤ņĀĆņÜ®ņĀæ ļ¬©ļŗłĒä░ļ¦ü ĻĖ░ņłĀņØ┤ Ļ░£ļ░£ ļ░Å ņĀüņÜ®ļÉśņ¢┤ņĢ╝ ĒĢĀ Ļ▓āņØ┤ļŗż.

PDF Links

PDF Links PubReader

PubReader ePub Link

ePub Link Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print